Enhance Your Ride with Custom Billet Motorcycle Parts

Explore the benefits of billet motorcycle parts, known for their strength, durability, and customizable design. Learn about the manufacturing techniques, materials, and finishes used to create these high-performance components. Discover why billet parts are a popular choice for motorcycle enthusiasts looking to upgrade their bikes.

Explain For Billet Motorcycle Parts

Billet motorcycle parts are components of a motorcycle that are manufactured from solid blocks of metal, typically aluminum. The term “billet” refers to a solid piece of material that is machined or CNC-milled to create a specific motorcycle part, such as handlebar risers, brake levers, foot pegs, or engine covers.

Advantages of Billet Motorcycle Parts

- Strength and Durability: Billet parts are known for their high strength and durability, making them suitable for withstanding the rigors of motorcycle use.

- Precision: The CNC machining used to create billet parts ensures precise and accurate dimensions.

- Aesthetics: Billet parts often have a distinctive, high-quality appearance that can enhance the overall look of a motorcycle.

- Customization: Billet parts can be customized with unique designs, colors, and finishes.

The Improvement of Performance or Handling by Billet Motorcycle Parts

CNC-machined motorcycle billet part (made of monolithic blocks of aluminum or steel) improve the following features of bikes — performance and handling. Built with high resilience, these components display enhanced hardness and resilience especially in corners like suspension components and triple clamps, in addition to reduction in weight which goes a long way in improving a vehicle’s handling, acceleration and all-round performance. Rigidity is the key factor, which creates firmness of chassis and ensures perfect transmission of force while applying pressure to the brake pedal. Thus, the vehicle becomes more handled dynamically. Besides these, billet parts enable riders to customize their motorcycles exactly in their preferred way, simultaneously the sleek finishes make both the functionality and the design better, which is to say, more beautiful. Wrapping it up billet parts combine all the qualities of strength, good design and the ability for modification that are fundamental for driving performance and control.

Types of Motorcycle Parts Can Be Made From Billet

From the selection of various types of motorcycle parts done in billet, lay the options of performance, durability and aesthetics in the trough. The list is comprehensive: single clamp, triple clamps, swingarm, footpegs with rear sets, and so on. Each of them is for better steering precision, suspension performance, and riders grip respectively. Similar to that, one can also incorporate something like billet handlebar risers as well as clip-ons to be able to customize their riding styles, and brake calipers and master cylinders provide consistent braking power along with superior heat dissipation. The shrouds is not only a protective measure, but it also smartens the look of the motorbike, while the billet levers simultaneously enhance the clutch and brake operation out of the motorbike. Other emmacisations do apart with the frame sliders, fuel caps, and wheels that play a role in enhancing the bike’s performance and aesthetics. One can see that near their inherent structural sturdiness and perfection machining, billet components continue to be the most wanted upgrades among people fascinated with motorcycles and opt for maximum performance options and variety of customizations.

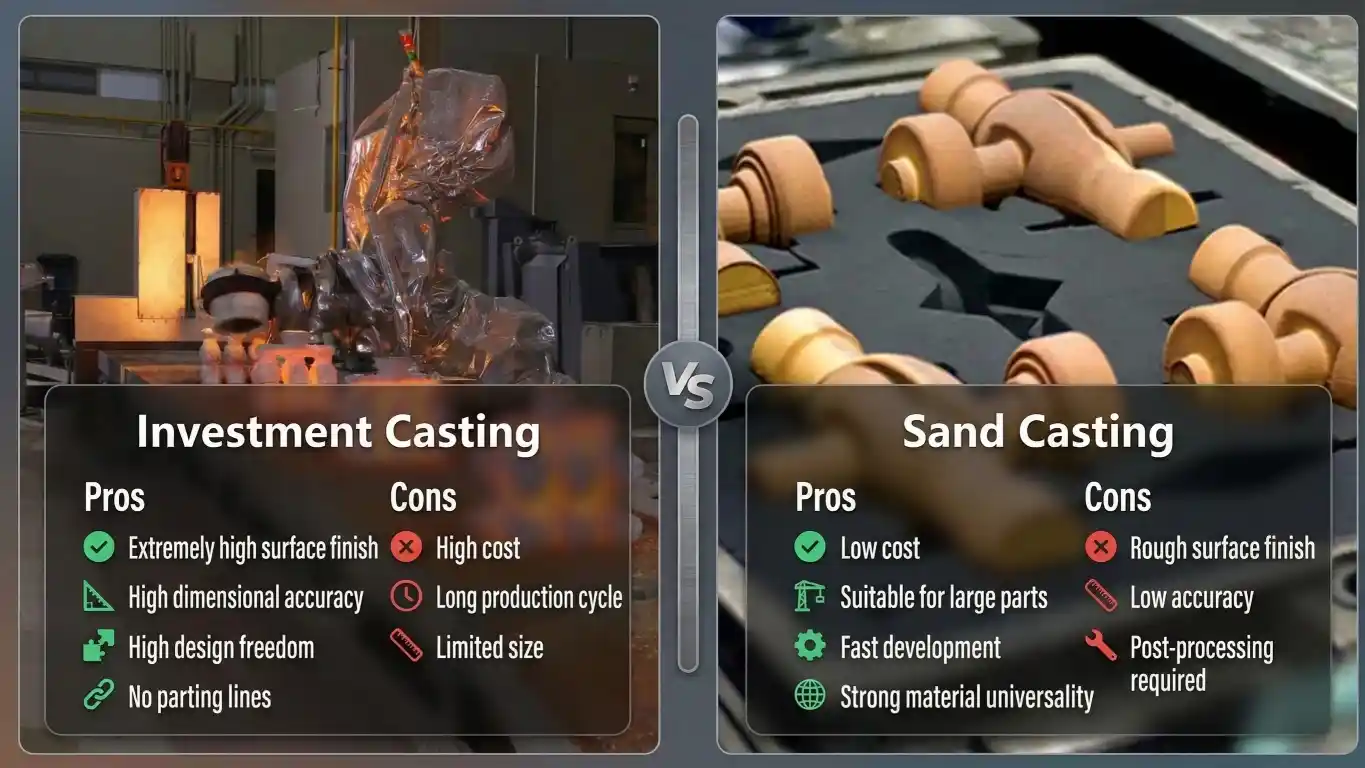

Manufacturing Techniques Can Be Used to Create Billet Motorcycle Parts

With many methods of the ways they are made for the motorcycle billings, each with its own set of benefits, revolves around the bikel-al industry. CNC machines are mostly used to produce detailed shapes and in creating customized spare parts while forging is mostly used in developing high-strength spare parts. Through die-casting, the creation of complex components is possible, and if parts resemble a tube or a rod, extrusion will be the chosen manufacturing method. With these production techniques, we may be able to achieve different levels of strength, difficulty, and expense. This would imply that the end product could be made of quality billet components for motorcycles.

Materials Typically Used for Billet Motorcycle Parts

Billet parts on a motorcycle are usually made of better materiels like aluminum or steel. Aluminum is a common pick apparently because of the weight feature it presents, corrosion resistance, and the machines can easily handle the metal. It gives a very good stiffness-to-weight ratio, this therefore makes it appropriate for various applications where weight is a key factor, like leg shields, steering stems and footrest. Steel however not only is resilient but also tough and within the high stressed regions such as frame section, mounts, and suspension system, it is mostly preferred. Whilst the steel billet parts may weigh heavier than their corresponding aluminum parts, they ensure toughness and ruggedness, which are both indispensable for the long-lasting performance of the precision-built components under the arduous and rigorous working conditions. Options between aluminum and steel are depend on propertier of the motorcycle part – weight, strength and performance.

Finishes Typically Used for Billet Motorcycle Parts

Billet motorcycle parts include all the machining processes from forging, heat treatment, polishing or anodizing, which add to the parts good look, durability, or resistance to corrosion. The finishing options include anodizing which creates an oxide layer that shields the surface. It offers customization via dyeing. Powder coating comes next and it ensures durability by having the capability of providing colorful finishes that do not easily chip or fade. Polishing comes in with smooth shiny finishes that can be further protected with clear coating or wax. The brushed finishes help to conceal imperfections and provide Finish options are selected based on factors like design tastes, product performance demands and cost restrictions, hence ensuring quality level over appeal and durability of billet motorcycle parts.

The Price Comparison of Billet Parts Versus Other Types of Motorcycle Parts

Billet motorcycle parts generally come at a higher price compared to other types of parts due to their CNC machined construction from solid blocks of premium materials. While cast or stamped parts are more affordable due to lower production costs, they may lack the strength, durability, and customization options of billet components. Ultimately, the choice between billet and other parts depends on factors such as budget, desired performance improvements, and aesthetic preferences.

Replacing Billet Motorcycle Parts and Its Impact on Warranty

Another essential factor to include when buying aftermarket parts for motorbikes is their influence on the guarantee. Normally, engine tuning with the help of aftermarket options such as billet parts, will terminate the warranty or alter the warranty terms stipulated by the OEM. Again, this is due to the reason that aftermarket parts may not meet the equivalend quality and safety guidelines as OEM (Original Equipment Manufacturer) parts. Yet, some producers could provide extended warranty for brand parts that are exclusively designed and approved by their manufacturers. It is important to look at the warranty policy provided by the motorcycle maker and discuss the possible effects of replacing billet parts if the warranty agreement is damaged with retailers or service providers. Moreover, keeping a maintenance log and a record of after-market installations will assist in the warranty claims, as well as to ensure the compliance with warranty rules.

Customize Billet Motorcycle Parts

- Determine your requirements, including design, finish, and any unique features.

- Find a reputable CNC machining shop or manufacturer experienced in custom billet part production.

- Provide detailed design specifications and requirements.

- Collaborate with the manufacturer to create the custom part.

- Ensure quality control and testing.

- Install the customized part on your motorcycle.

- Enjoy the personalized and enhanced performance or aesthetics of your motorcycle.

Conclusion

Billet Motorcycle Parts are an excellent choice for riders looking to enhance their motorcycle’s performance and appearance. The ability to customize these parts ensures that your bike is a true reflection of your style and preferences. So, why wait? Upgrade your ride and hit the road with confidence, knowing you’ve chosen the best for your motorcycle.

The most ideal surface finish is available here in HDC, you can choose from anodizing, hard anodizing, powder coating, etc. We make sure to give the strictest inspections in every part for you to have faultless billet motorcycle parts.

Here in HDC, We also produce lots of billet parts for Cars, racing karts,bikes and so much more!

We provide one stop solution for metal parts, we also offer CNC machining services, turning services, sheet metal fabrication services for your metal parts.

With all the processes and services, we will also let you pick and custom your packaging according to your requirements. We provide shipping methods such as land, sea, and air. The payments will go through Paypal, T/T, or L/C depending on your choice. Trade terms will never be an issue for we have FOB, CFR, and DDP.

Experience the best services for billet motorcycle parts here in HDC!

Discover more with our blog posts.

Recent Posts

Discover more about our products

HDC Products

Instant Quote!