Unlocking the Potential of CNC Milling Services

Dive into the world of CNC milling services, exploring their significance, applications, and benefits. Learn about the different types of CNC milling machines, materials, tolerances, and post-processing options. This guide will help you understand how to leverage CNC milling for your manufacturing needs.

Understanding CNC Milling

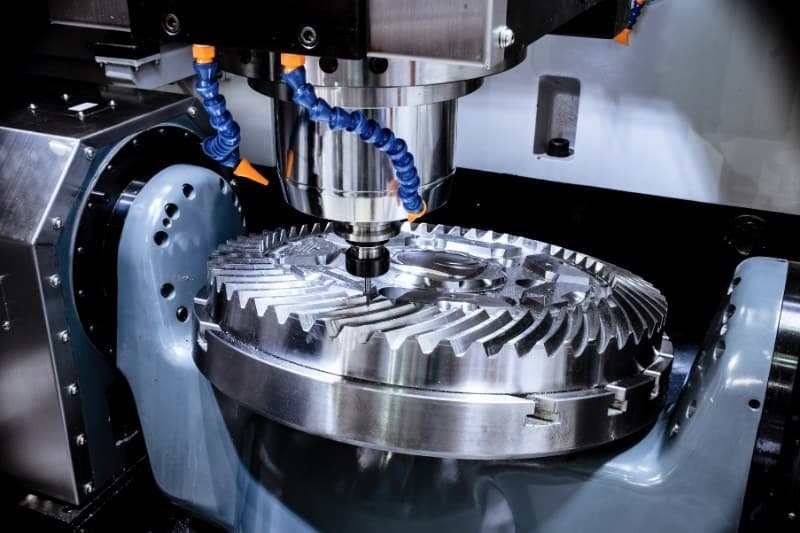

CNC milling is a machining process used to remove material from a workpiece to create a desired shape, part, or product. In CNC milling, a computer program governs the movement and operations of a cutting tool, commonly a rotating, multi-point cutter, as it eliminates material from a workpiece that is usually secured to a worktable. This precise and automated process allows for the creation of intricate and highly accurate components used in a wide range of industries, from aerospace and automotive to manufacturing and electronics. CNC milling offers exceptional repeatability and the ability to produce complex geometries with precision.

Components Make Up a CNC Milling Machine

- Worktable

- Spindle

- Tool Holder

- Control Panel

- Axis Movement System (X, Y, Z axes)

- Drive Motors

- CNC Controller

- Coolant System

CNC Milling Vs. CNC Turning Vs. CNC Grinding

CNC Milling:

- Involves a cutting tool moving to shape a stationary workpiece.

- Used for complex parts with various shapes and holes.

CNC Turning:

- Uses a rotating workpiece and a stationary cutting tool.

- Ideal for cylindrical parts with rotational symmetry.

CNC Grinding:

- Employs a rotating grinding wheel to achieve high precision.

- Used for extremely accurate parts with a fine surface finish.

Types of CNC Milling Machines

There are various types of CNC milling machines, including vertical and horizontal machining centers, and gantry mills for different machining tasks and workpiece sizes. 5-axis machines enable intricate part milling while micro-milling machines excel in precision for small components. The choice of machine depends on the specific job requirements, including material, part complexity, size, and production volume, with each type offering unique features and capabilities.

Distinguish CNC Milling Machines With Varying Axis Numbers

The number of axes in a CNC milling machine determines its flexibility and the complexity of parts it can create. 3-axis machines move in three directions (X, Y, and Z), while 4-axis and 5-axis machines can also rotate the workpiece, allowing for more intricate cuts.

Primary Applications of CNC Milling in Various Industries

- Aerospace: Aircraft components, engine parts, and structural elements.

- Automotive: Engine blocks, transmission components, and intricate parts.

- Manufacturing: Molds, dies, and custom components.

- Medical: Implants, prosthetics, and surgical instruments.

- Electronics: PCB fabrication.

- Defense: Military equipment and weapon parts.

- Woodworking: Furniture, cabinetry, and crafts.

- Mold Making: Molds for plastic injection molding.

- Energy: Parts for renewable energy systems.

- Custom Fabrication: Unique, highly detailed pieces in art and custom fabrication.

- Marine: Ship components in shipbuilding.

- Packaging: Custom packaging molds and prototypes for the packaging industry.

Types of Materials Can Be Processed Using CNC Milling

- Metals: Aluminum, steel, stainless steel, brass, and copper.

- Plastics: ABS, acrylic, polycarbonate, nylon, and more.

- Wood: Hardwood, softwood, and wood-based materials like plywood.

- Composites: Carbon fiber, fiberglass, and Kevlar.

- Ceramics: Advanced CNC milling can machine ceramics.

- Foam and Foam-like Materials: Polyurethane foam, EPS, and polyethylene foam.

- Glass: Specialized CNC machines can be used for glass milling.

Tolerances and Precision Achievable With CNC Milling

The achievable tolerances and precision typically depend on various factors, including the machine’s capabilities, tool quality, and the material being machined. CNC milling can often achieve tolerances within the range of ±0.005 to ±0.001 inches (0.127 to 0.0254 mm). These are suitable for most common applications.

Limitations in Terms of Part Size or Complexity for CNC Milling

CNC milling machines come in various sizes, from small tabletop units to large industrial machines. The choice of machine depends on the size and complexity of the part. Large and complex parts may require specialized equipment.

Post-processing and Finishing Options Are Available for CNC-Milled Parts

CNC-milled parts can undergo various post-processing and finishing techniques, including sanding, polishing, anodizing, or painting, depending on the material and the desired appearance of the final product.

Aspects Should Be Considered When Customizing CNC Milling Parts

When customizing CNC-milled parts, factors such as material selection, design, tolerances, and post-processing should be carefully considered. Collaborating with experienced engineers can help ensure your project’s success.

Find a Reliable CNC Milling Service

For a dependable CNC milling service, turn to HDC. With a rich history of over 13 years in customized metalwork, we offer samples to guarantee quality. What sets us apart is our commitment to assisting you in the design process, material selection, and the whole process of customizing, ensuring your project’s success. Our in-house facility, experienced engineers, and various manufacturing techniques, including CNC processing, make us a reliable choice. Additionally, we have 4-axis and 5-axis CNC capabilities for intricate projects.

Conclusion

CNC milling services play a vital role in modern manufacturing, enabling the production of precise and complex parts across various industries. By understanding the basics and nuances of CNC milling, you can make informed decisions and leverage this technology for your specific needs.