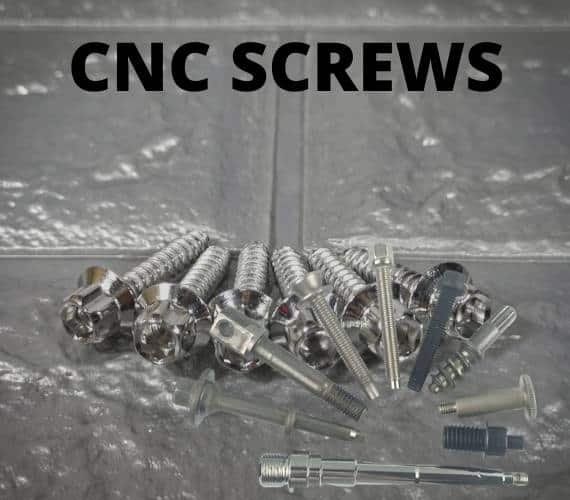

HDC is Your Reliable CNC Screws Supplier in China.

HDC, as an ISO9001 certificated CNC Screws manufacturer in China, we can provide a one-stop solution for your requirements. More than 13 years of OEM CNC screw experience, HDC can support your new product development. Ask for a quick quote now.

- More than 50 certified materials in-stock

- 10+ Anodized surface treatment for your CNC screw

- Tailored CNC screws based on your design

- Free samples provided for your approval

- 100% quality guarantee before shipment

HDC- Expert CNC Screws Manufacturer

If you are looking for the most reliable CNC screws manufacturer in China, HDC is here for you. We manufacture and supply all types of CNC screws worldwide. HDC CNC screws are also available in custom designs, rest assure your design is protected. Samples are provided for free.

We are already engaged in manufacturing CNC screws since 2006, therefore we can guarantee you high-end CNC screws for a competitive cost. Whether you need it for business or personal needs, HDC is the name you can surely trust.

Custom Your CNC Screws with HDC

Applicable in multiple industries like manufacturing plants, machinery repair shops, etc. Features excellent reliability, rigidity, durability. ISO9001 certificated parts. Length can be customized as per request.

Made of stainless steel material. HDC lead screw CNC comes with a lifetime warranty. There is more than 10 surface treatment you can choose from. Get high-accuracy lead screw CNC to support your business.

Ideal for use in manufacturing plants, machinery repair shops, retail, and home use. CNC ball screw can be pre-produced for you to check quality. We will protect your own design CNC ball screw from others.

HDC CNC screw rod offers long operating life, highly precise. We offer OEM customize service includes material selection, surface treatment, and more. Free samples are provided for your approval.

CNC screw drive can be used for building material shops and manufacturing plants. We offer minimum order quantity for as low as 50 pcs CNC screw drive. One-stop solution will be provided.

As an expert manufacturer, HDC offers a one-stop solution for your CNC screw machine needs. Components offered at a consistent competitive cost. Pre-production of your cast iron CNC screw are provided for quality checking.

HDC 5mm lead screw CNC can be customized to your unique business requirement. You can get your logo etching on your component. We will deliver your product from 7-14 days according to quantity.

HDC manufacture and supply 100mm CNC router ball screws for a variety of industry use., including manufacturing plant, machinery repair shops. Free samples of your design are available.

This CNC racing titanium screw comes with a lifetime quality guarantee. All parts are strictly inspected before leaving the factory. We will keep your design protected.

Why HDC CNC Screws

HDC is composed of skilled engineers that focused on the balance of the quality and cost of our CNC screws. As an ISO 9001 certified company, we can make sure that we produce top-quality products with guaranteed performance.

We are supplying CNC screws for more than 50 countries around the world. Our skilled team will give full support to skyrocket your business sales.

HDC Capabilities on Custom Your CNC Screws

Comprehensive FAQ section dedicated to Custom CNC Screws.

Custom CNC screws are precision-engineered fastening solutions that cater to unique requirements across various industries. These screws are manufactured using Computer Numerical Control (CNC) machining, a precise and automated method that ensures exceptional accuracy and reliability in their design and production.

Q1: What are custom CNC screws?

Custom CNC screws are specialized fasteners manufactured using Computer Numerical Control (CNC) machining techniques. They are tailor-made to meet specific requirements in terms of dimensions, materials, threads, and features, catering to unique applications.

Q2: What are the advantages of custom CNC screws compared to purchasing bulk standard production screws?

Custom CNC screws provide precise measurements, special features, and materials tailored to boost performance and efficiency. This results in a superior fit, improved functionality, and overall better product quality when compared to standard screws.

Q3: How are custom CNC screws designed and manufactured?

Custom CNC screws are designed using computer-aided design (CAD) software, allowing precise specifications to be defined. These designs are then translated into machine-readable code for CNC machining, where automated tools carve out the intricate details of the screws from raw materials.

Q4: What industries benefit from using custom CNC screws?

Custom CNC screws find applications in a wide range of industries, including aerospace, automotive, electronics, medical devices, robotics, and more. Any field requiring precise and specialized fasteners can benefit from custom CNC screws.

Q5: What materials can be used to manufacture custom CNC screws?

Custom CNC screws can be manufactured from various materials, such as stainless steel, aluminum, brass, titanium, and engineering plastics. The material choice depends on factors like strength requirements, environmental conditions, and regulatory considerations.

Q6: Can custom CNC screws accommodate unique thread profiles and features?

Yes, one of the main advantages of custom CNC screws is their ability to incorporate unique thread profiles, head styles, and features such as knurling, fluting, or specialized coatings, providing tailored solutions for specific applications.

Q7: How does the precision of CNC machining impact custom screw quality?

CNC machining ensures high precision and consistency in custom screw production. This accuracy leads to reliable thread engagement, consistent dimensions, and minimal tolerances, enhancing overall quality and performance.

Q8: Are custom CNC screws compliant with industry standards and regulations?

Yes, custom CNC screws can be designed and manufactured to meet industry-specific standards and regulations, making them suitable for applications that require adherence to strict guidelines, such as medical devices or aerospace components.

Q9: How can I order custom CNC screws for my project?

To order custom CNC screws, you can work with manufacturers or machining shops that offer CNC services. Provide them with your design specifications, quantity requirements, and any specific features needed for your application.

Conclusion:

One of the standout advantages of custom CNC screws is their ability to enhance efficiency and performance. Whether it’s optimizing load distribution, reducing wear and tear, or ensuring compatibility with unique structures, these screws deliver tailored solutions that translate to improved overall product quality.

HDC CNC Screws

HDC has been manufacturing CNC screws for more than 13 years. We have a wide range of CNC screws in different sizes, shapes, and sales. HDC can provide small to large orders for CNC screws. If you need CNC screws to add to your current line, this one from HDC is your best choice.

You can choose more than 10 different surface treatments for CNC screws. Our advanced manufacturing allows us to produce CNC screws that have the capability to showcase your company in the market.

With our years of experience in OEM services, we have been tested by our customers in more than 50 countries; trusted us for many years. All parts of CNC screws are carefully checked by our skilled workers before shipment.

HDC CNC screws can be designed according to your specific ideas. We can assure you that your designs are safe and secure. Our advanced manufacturing system maintains the quality of our products consistently.

We provide free samples for you to check the product’s quality first then add your orders afterward. HDC aims to be your most reliable manufacturer of CNC screws. We are one-stop solutions in this field.

You can send us your inquiries anytime.

Our assigned engineers’ consultants will help you find your ideal CNC screws. For shipment, whether it’s air shipping or sea shipping, you are free to choose.