5 axis milling services

5 axis milling services provide a unique level of freedom in the preparation of complex and intricate custom parts. 5-axis machines have the option of working on the part from 5 different axes. The 5 axes of the machine consist of three linear axes i.e. X, Y, and Z axes, and two rotary axis A (parallel to the X axis), and B (parallel to the Y axis) on which you can rotate the part.

The major application of 5 axis milling services are:

- Aerospace Industry

Manufacturing of hydraulic blocks, engine parts, control surfaces, aerodynamic surfaces, etc.

- Medical Industry

Used for manufacturing of surgical tools, MRI/CT Scan machine parts, Hemodialysis machine parts, etc.

- Military

Used in manufacturing of gun parts, missile parts, projectile parts, ammunitions, locomotives, etc.

- Energy Equipment

For manufacturing of Gas turbines, Steam turbines, Boiler parts, Fuel Tank parts, etc.

Advantages of Using 5 axis milling machine

5 axis milling machines provide a variety of advantages over 3 axis machines as follows:

Provides higher machining accuracy

with the advanced tools and 5 axes available for work, the accuracy of the final product increases manifolds.

Can work effectively on hard surfaces

for instance, the Cubic Boron Nitride (CBN) and Polycrystalline diamond (PCD) tools, coupled with the higher cutting speeds, make it possible for the machine to work on surfaces as hard as 60 HRC with a precision of 5 microns and that too with keeping the surface roughness level to 15 microns.

Cost-effective

5-axis machines provide a cost-effective solution by reducing the production time and requirement for refining and reworking of the products.

Possibility to create complex custom parts

because of the ability to produce complex designs with the 5-axis machines, it is possible to produce complex custom parts that are not easy to produce otherwise. Furthermore, the enhanced designing options enable to the production of parts that are minute in size and require a separate setup for manufacturing.

Saves time

5 axis machining saves considerable time in the manufacturing of complex parts. Also, since there is minimal involvement of manual labor, the efficiency is higher and the process is more effective.

Specification and usage of 5-axis milling services

In comparison to the 3-axis machines, 5-axis milling machines provide higher accuracy and efficiency when creating complex custom parts.

5-axis milling machines can be configured in 3 + 2, 4 + 1, and full 5-axis configurations. Depending on the complexity of the design and the level of precision required the final configuration is selected.

5 axis milling services provide high precision and accuracy for the products. The service works perfectly well on materials made from Stainless Steel, Aluminum, Titanium, Inconel, and other metallic alloys. With 5 axis milling machine, it is possible to create complex designs in short times that will take a very long time for manufacturing otherwise.

The 5-axis milling machines are ideal for working on parts with slopes, contours, cavities, and other complex areas where normal CNC machines cannot operate.

Why choose HDC?

HDC has a vast experience in manufacturing with 5-axis milling machines. Therefore, HDC’s 5-axis milling services are top of the line. Furthermore, we have a dedicated team that works with the CAD/CAM section. Here we produce unique and exquisite designs that enable us to prepare high-quality custom parts for the market.

We at HDC fully understand the importance of compliance with regulatory standards. Therefore, we will ensure that the custom part you get fully complies with the regulatory standards of the industry, be it Aerospace, Military, or Medical industry.

5-Axis Milling Services FAQS

It’s rare to find manufacturers that offer 5-axis milling services perfectly and flawlessly, simply because of the fact that this process is extremely complex and comprehensive – not for us here at HDC Manufacturing, though! We’re able to help you produce whatever part or component you need via 5-axis milling and processing!

Not sure what 5-axis milling services means? Or do you have related questions to that? Don’t worry, we present to you this quick and easy FAQ guide to help you with what you need!

What Does 5-Axis Milling Mean?

5-axis milling is one of the types of complex machining processes where the number of “axes” or directions the cutting tool follows would be five (5). In milling, usually, the cutting tool will flow and follow a single axis, moving from the X and Y planes.

With 4 other additional axes, it can move across an X, Y, and Z linear axes and can even rotate and move into a different one depending on the program set.

How Do 5-Axis Milling Machines Function?

The working principle of a 5-axis milling machine wholly relies on A, B, X, Y, and Z rotations and movements. So, for instance, if you were to machine or process a workpiece and you need it to be 3-dimensional in size, form, and shape, you can use a 5-axis milling machine in order to capture every angle there is on a milling machine.

To help and guide you with how 5-axis milling machines work, here’s a quick and simple step-by-step procedure on how it operates and works:

- The workpiece is mounted onto the 5-axis milling machine.

- Then, the program or the software is set according to the wanted and/or needed results.

- After that, the machine is set for a dry run to test and check if it will follow through the program.

- Then, lastly, ensure that the workpiece is properly secured onto the chuck of the milling machine and then proceed to continue the program.

NOTE: These aren’t the usual steps that are followed by ALL manufacturers and companies. Of course, you will find and encounter some suppliers that follow different sets of steps to be able to accomplish it.

What Are the Different Types of 5-Axis Milling Machines?

There are a few different types of 5-axis milling machines that manufacturers make use of to build their projects and components. Some find it difficult to identify, but there are a couple of experts that know these by heart.

So, the different types and categories of 5-axis milling machines include:

- Drop Swivel Head

- Drop Table

- Double Swivel Head

- Double Swivel Table

- One-Swing, One-Rotate

The primary differences between these 5-axis milling machines would be in terms of the location of where the rotational axes on the machines appear. They’re highly different, but mostly, the results they have would be similar and the same.

What Materials Can 5-Axis Milling Machines Work On?

Different 5-axis milling machines are capable of working on a wide range of materials; especially since most 5-axis milling machines (if not all), are CNC or computer numerically controlled machines.

The most common materials and workpieces that are accepted by 5-axis milling machines to be worked on include, but are not limited to:

Aluminum

Aluminum is the easiest and the fastest alloy that 5-axis milling machines can work on. They have excellent strength-to-weight ratio, and they have decent electrical and thermal conductivity.

Stainless Steel

These are alloys that are decent to machine due to the fact that they are extremely resistant to wear, corrosion, warping, and distortion.

Carbon Steel

Typically, carbon steel is the type of steel that is used for fasteners, therefore, carbon steel is also commonly referred to as “tool steel.”

Titanium

Titanium has excellent levels of corrosion, abrasion and temperature resistance. It is the perfect package and is ideally part of the best materials for various machines and equipment.

Nylon

Lastly, nylon, Nylon is a multi-purpose material that can be used for varying purposes, and one of this would be as an alternative to metal and steel.

What Industries Require 5-Axis Milling Machines For Their Components?

There are many different industries and sectors where 5-axis milling machines are used for. Typically, though, the industries where they are most used include, but are not limited to:

- Automotive Industry

- Aerospace and Aeronautical Sectors

- Oil and Gas Industries

- Medical, Medicinal, and Pharmaceutical Sectors

- Tools Manufacturing and Production

- Industrial Sector

- And Many More!

What Parts and Components Can You Produce With 5-Axis Milling Machines?

5-axis milling machines are specifically used for the purpose of manufacturing highly complex parts and components. Naming them would be endless, especially in the medical and pharmaceutical sectors. To cite some of the concrete products, they include: –

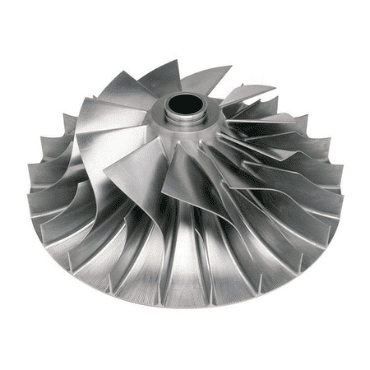

- Turbine Blades

- Engine Parts

- Defense Industry Weapons

- Automotive Industries

- And Many More!

Where Can You Get Premium 5-Axis Milling Machine Services?

Here in China, you will never get a shortage of 5-axis milling machines, especially if you require quality, precision, and accuracy. But out of all the many different types and kinds of manufacturers and suppliers, no other manufacturer was able to top our quality here at HDC Manufacturing.

We have produced many different types of products using our 5-axis milling services to various industries and sectors there is. Whether you need services for one-swing rotate, drop table, drop swivel head, or many more, you can place your full and complete trust in us!

Besides 5-axis milling services, our experts and professionals here at HDC Manufacturing are also skilled and capable of helping you with metal stamping services, CNC rapid prototyping, sheet metal fabrication services, laser cutting, and many others more!

Drop a message and send over the question or concern you have together with a sketch so we can give you an instant estimate of how much budget you’ll be needing for this project.

Contact us today and get a quote within a few hours!

[toc]