17 Types of Milling Operations That You Should Know

- By: HDCMFG

Are you looking for the right milling operations to get components with your desired shape and finish? If yes, then you have come to the right place. Here we’ll provide an in-depth analysis of almost 17 types of milling, discussing their working and uses. Also we’ll tell which factors you have to consider before choosing any milling type. So, keep reading!

Understanding the basics of milling operations

“Milling is actually a type of subtractive manufacturing in which a milling cutter removes material from the workpiece to achieve the required shape.”

For your information, the first milling machine was invented by Eli Whitney in 1818 to manufacture rifles for the U.S. government. Well! The working principle of all types of milling machines is generally the same, like just the cutter being rotated against the stationary or moving workpiece. Thus the material is removed layer by layer to shape it as you wish.

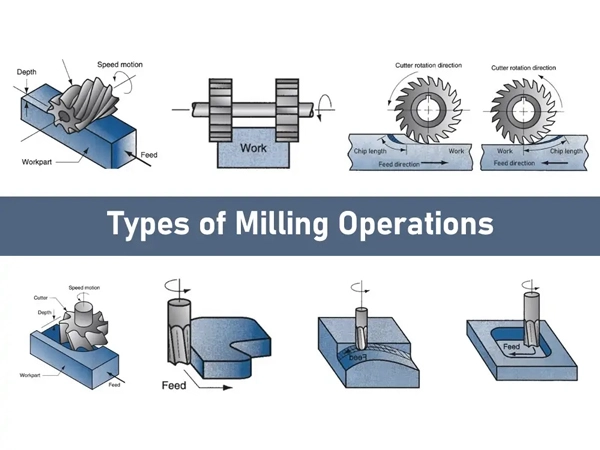

Common Types of milling

Alright! There are different types of milling operations, each gives you a specific shape component. Here, I have categorized all based on their working operations and cutters. So, it doesn’t create a mess, and you easily understand all and choose one according to your needs.

Trust me! Most of the milling types’ names are self-explanatory, like showing what they do or how they work. So, let’s get started!

Types of Milling Based on Cutters and Movements

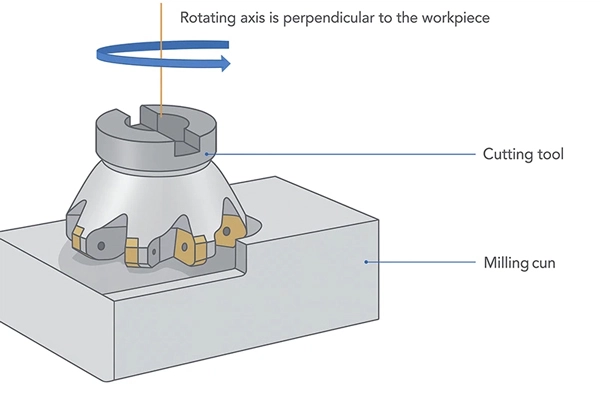

1. Face Milling

Face milling is a beloved process in manufacturing industries as it is actually used to smooth the uneven surfaces. Here actually, the cutter moves in an axis perpendicular to the workpiece ( stationery or slowly moving). You can also control the depth & feed rate of this cutter.

As a result, when the cutter spins, its sharp teeth remove the workpiece material from the top layer, thus efficiently producing a flat surface.

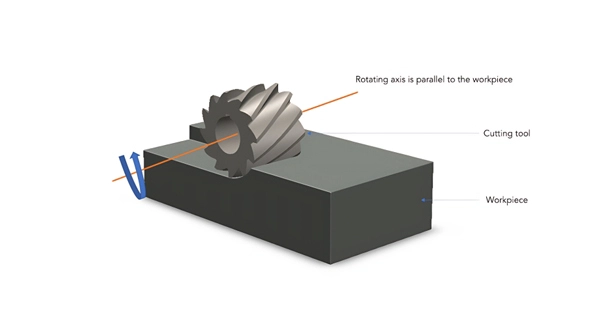

2. Peripheral (or Plain) Milling

Next, if we talk about the peripheral milling, then you can say it’s the opposite of the face milling. This is because, unlike face milling, here the cutter is placed in an axis parallel to the workpiece. As a result when the cutter rotates then it would actually remove material from the sides or edges of the workpiece, not the top one. Okay!

Thus, you can say that this milling operation is best for making grooves or slots along the workpieces.

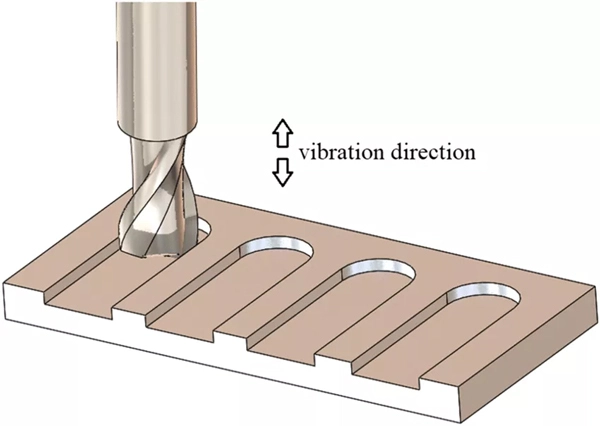

3. End Milling

End milling is the most versatile milling operation among all, as the cutter used has actually cutting edges on both ends or sides. Thus, you can use it to produce pockets, slots, or even contours in the workpieces. Well! You can imagine it like a drilling machine, but the difference is that a drilling machine just cuts straight down, but it can cut sideways too.

4. Shoulder Milling

In this type of milling cutter is usually placed vertically or slightly angled compared to the workpiece. Thus it moves horizontally alongside the workpiece and as the name suggests, the material is actually removed from the sides of the workpiece ( say, its shoulder) to create the 90-degree flat vertical surfaces.

5. Side Milling

Side milling is similar to shoulder milling, which both cut the materials from the sides of workpieces. But the difference here is that in side milling, our main purpose is to cut the material along the sides to make grooves, slots or shape edges.

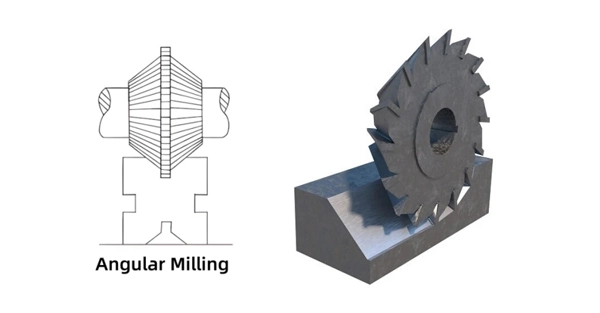

6. Angle (Angular) Milling

On the other hand, in angle milling, you use the specialized milling cutters like tapered one that are flare or cone-shaped but can be adjusted to the desired angle. So, here, you would actually place such cutter at a specific angle relative to the workpiece ( not parallel, not perpendicular). So, when the cutter rotates, it would remove the material from the angled surface, thus used to create precise slanted, bevel, or chamfered edges.

7. Slot Milling

As the name suggests, you can use the slot milling operation to carve a channel of any size in the material, which you say like grooves or slots. You can do this job with a slot cutter, which basically looks like a circular saw blade, allowing you to cut the sides of material from the workpiece.

8. Form Milling

As compared to the above types mentioned above, in form milling the shape of the cutter actually demons on the pattern you want to create on your workpiece. So as this cutter rotates, it carves its exact shape onto the material. You know form milling is the most popular cutting technique deployed in the automotive, aerospace or mold-making.

9. Profile Milling

So, if you want to create complex shapes on your workpiece material, then profile milling would be your go-to. This is because it uses a tool that has multiple cutting edges, which can cut the material along the side or angle according to your desired pattern. Also it has ball tip that moves around to smooth the surface.

Thus, profile milling is an ideal or more practical choice for creating dies, mold or other things with more detailed work.

10. Saw (SAW) Milling

Similarly, in saw milling, the cutter used is very large, thin, and lot of teeth just like a saw blade. Well! The blade can cut the material straight down vertically or rotate along the workpiece to create different types of precise cuts or grooves in the materials.

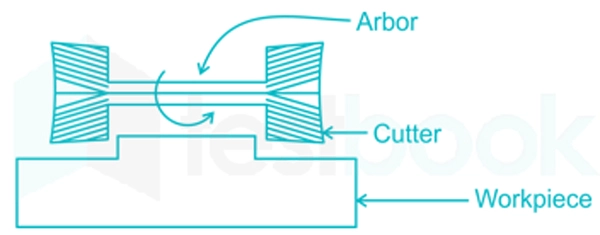

11. Straddle Milling

However, in straddle milling, there are actually two cutters that are attached to the same arbor on opposite sides of the workpiece. Thus owing to this setup up they have the capability to cut even two parallel surfaces at the same time while maintaining a uniform distance between them.

Types of Milling Based on Machine Operation

12. Conventional Milling

Conventional milling, also called up milling, is actually a traditional cutting method deployed in older machines. Here actually, the cutter rotates in the opposite direction to the workpiece material movement.

Well! At the start, it cuts slightly, but by the end it becomes aggressive and cuts out the thicker material to produce smooth finishes even in the hard materials. However, this aggressive scraping may wear out the cutter eventually.

13. Climb Milling

On the other hand, climb milling ( down milling) is somehow a modern alternative to up milling that works totally opposite to conventional milling. For instance here the cutter moves in the same direction as of workpiece movement.

Thus, here by the end material cutting becomes thinner, which reduces the heat or friction. This minimizes the chances of the cutter wearing out and produces even smoother finishes.

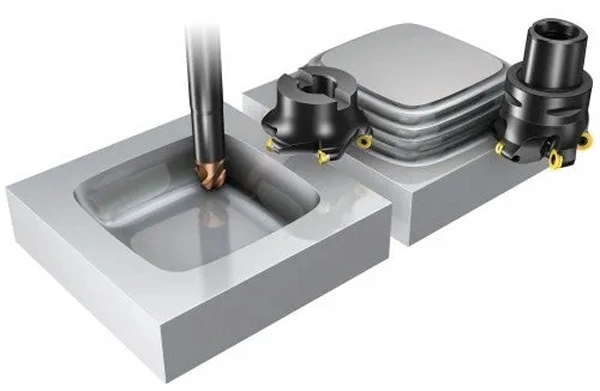

14. CNC Milling

CNC milling is today’s modern operation in which computer-controlled machines are actually used to automatically perform the cutting processes. Thus you would get highly accurate or precisely shaped complex components, eliminating the chances of any human error.

For your information, we at HDC MFG offer customized CNC milling services using four-axis and five-axis machines to handle complex manufacturing tasks with 16-125 microinches surface finishing. So, get in touch with us today for effective CNC milling solutions at an affordable price.

Special Types of Milling

15. Gang Milling

Just like its name, yes in this milling type, there is actually a gang of cutters that are placed on the same arbor, each performing its own special task. Thus, I must say that this is the best if you want to get high productivity and save time, as it does multiple tasks simultaneously.

16. Rotary milling

Just like gang milling in rotary milling, there are also several cutters, but all of these are attached to the rotary table or head. Also here the workpiece rotates continuously instead of linear movement, thus each cutter removes the material from different areas. Thus, this method is best for mass production as it saves time.

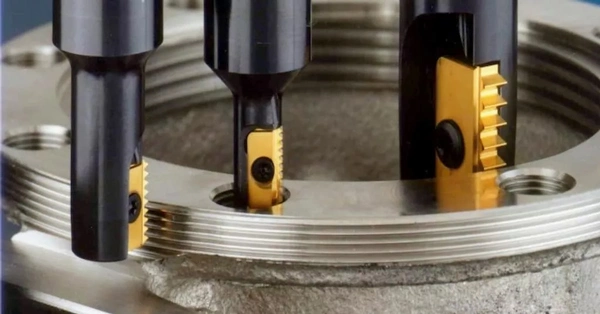

17. Thread Milling

Last but not least, thread milling, as the name suggests, is used to create the thread (internal or external spiral ridges) in the workpiece. So, to do this, it uses the roating cutters instead of tapping, thus the cutter moves circularly and downward and produces large threads in the workpiece.

How to Choose the Right Milling Type?

Now, you are aware of almost all types of milling operations, right? So, if you want to choose between any of the above-mentioned types, then you should consider some factors in mind before making a decision. So for your convenience, here I’m going to discuss these factors so you may better choose what suits your needs.

- Material Type: First of all, you should consider the properties of your workpiece material, like its hardness, toughness, or thermal conductivity. This is because all such properties actually influence a lot how easily would material can be machined. For instance, if the material is hard like tool steel, then conventional milling would be fail here.

- Desired Finish: Next you should pause and think about the surface finishing required for your desired material. This is because each operation produces a surface with different roughness levels. Look at the table below!

Face milling End milling Slot milling Thread milling Shoulder milling Form milling Profile milling Typical Roughness Ra (μm) 0.8 – 3.2 0.8 – 6.3 1.6 – 6.3 1.6 – 3.2 1.6 – 3.2 0.8 – 3.2 0.8 – 3.2 - Geometric Complexity: Furthermore, keep in mind that not all milling operations produce complex shapes. For instance, plain, face and slot techniques actually produce simpler shapes. On the other hand, end or thread milling is best at producing complex shapes with precision.

- Production Volume: Similarly, if your main concern is mass production at a faster rate then CNC or gang milling would be the best.

- Select the Right Cutter: Lastly, it’s worth noting that each of the above-mentioned milling types gives you the best results with a specific type of cutter. For instance;

- Face mills for large flat surfaces

- T-slot cutters for grooves

- Thread mills for threaded parts

- End mills for pockets, slots, and contours

Conclusive Remarks

From all the above discussions, we have concluded that there are various types of milling operations available, each producing specific shapes. However, before choosing any type, you should consider different factors like type of material, cutter, the desired finish, etc in this way, you could get the best results that suit your project needs.

If you want customized CNC milling services for producing complex shapes required for your project then look no further than HDC MFG. We offer services for 50+ metals and plastics at affordable prices. So, contact us today. We have years of experience in

Discover more with our blog posts.

Recent Posts

Discover more about our products

HDC Products

Instant Quote!