- Casa

- Capabilities

- Aluminum Forging Service

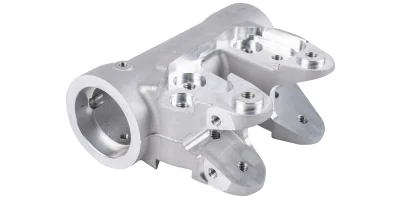

High-Performance Aluminum Forgings for Automotive & Industrial Applications

HDC specializes in precision 6061-T6 and 7075 aluminum forgings with ±0.15mm dimensional accuracy. Equipped with 1500-ton hydraulic presses and CNC machining centers, we deliver:

✓ ISO 9001-certified forged aluminum structural components

✓ Custom automotive suspension parts & engine mounts

✓ High-strength aluminum forged products for industrial machinery

✓ Heat-treated aluminum alloy forgings (T6 tempering)

Trusted by global manufacturers for critical aluminum forging solutions

6 Technical Advantages of Forged Aluminum Alloys

Why Forged Aluminum Outperforms Casting & Machining

Superior Strength-to-Weight Ratio

Forged aluminum achieves 30% higher tensile strength than cast counterparts, with 6061-T6 alloy reaching 310 MPa yield strength – ideal for structural aerospace components.

Precision Grain Structure

Directional grain flow in die forging enhances fatigue resistance by 25%, critical for automotive suspension arms and robotic joint assemblies.

Corrosion Resistance

Natural oxide layer provides 5x better corrosion resistance vs. steel, meeting ASTM G85 standards for marine applications.

Thermal Conductivity

205 W/m·K heat dissipation in 6061 alloy outperforms titanium, essential for EV battery trays and power electronics.

Mass Production Consistency

Closed-die forging ensures ±0.2mm dimensional tolerance across 10,000+ unit batches.

Material Utilization

95%+ material yield rate reduces waste compared to CNC machining.

Trusted Aluminum Forging Partner Since 2011

13 Years of Precision Engineering Expertise

Advanced Manufacturing Capabilities

🔹1500T Hydraulic Forging Presses with Real-Time Monitoring

🔹Integrated CNC Machining & Surface Treatment Centers

🔹ISO 9001-Certified Quality Management System

Multi-Stage Quality Assurance

🔹Material Analysis: Spectrometer chemical verification

🔹Process Monitoring: Infrared temperature control

🔹Precision Validation: CMM dimensional inspection

Operational Excellence

🔹15% Higher Production Efficiency vs Industry Average

🔹90% On-Time Delivery Rate (2021-2023 Average)

🔹Material Recycling Program: 75% Scrap Metal Reuse

Environmental Commitment

🔹Energy-Efficient Induction Heating Systems

🔹Closed-Loop Water Cooling Circuits

🔹Continuous Improvement in Waste Reduction

Materials Offered by HDC for Custom Aluminum Forging

Explore the high-quality aluminum alloys we provide for superior die forging results.

6061-T6 Aluminum

✓ 310 MPa Yield Strength | 27% Elongation

✓ Automotive Control Arms | Drone Frames

✓ Weldable & Anodizable

7075-T6 Aluminum

✓ 503 MPa Tensile Strength | AMS-QQ-A-365 Certified

✓ Helicopter Rotor Hubs | Flight Control Systems

✓ Stress-Corrosion Resistant

5083-H32 Aluminum

✓ 215 MPa Yield Strength | ASTM B928 Compliant

✓ Shipbuilding Components | Offshore Platforms

✓ Seawater Corrosion Resistance

6082-T6 Aluminum

✓ 340 MPa Ultimate Strength | EN 573-3 Standard

✓ Railway Bogies | Construction Machinery

✓ Machining-Friendly

2024-T3 Aluminum

✓ 470 MPa Ultimate Strength | AMS 4037 Certified

✓ Aircraft Wing Ribs | Hydraulic System Parts

✓ 100,000+ Cycle Durability

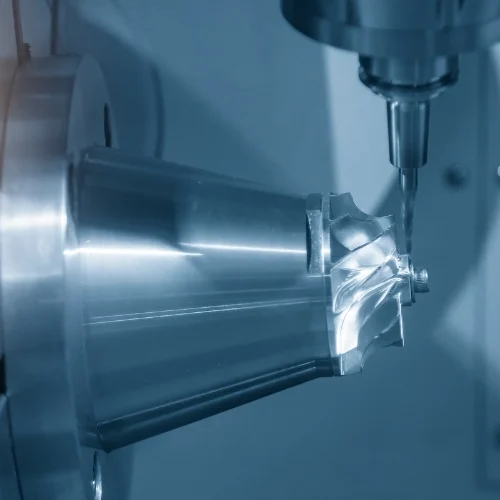

Aluminum Die Forging: Process Innovations & Engineering Solutions

Balancing Performance with Production Realities

Standard Aluminum Die Forging Process

- Material Certification: Aerospace-grade alloys (6061/7075 series) undergo spectrochemical analysis.

- Billet Conditioning: Precision induction heating systems achieve optimal forging temperature (400-500°C range) with ±25°C uniformity, preparing homogeneous grain structures.

- Die System Preparation: High-grade tool steel dies with conformal cooling channels undergo finite element analysis (FEA) to optimize material flow patterns and die longevity.

- Precision Forging: Closed-die forging under 50-200MPa pressure achieves near-net-shape forming with directional grain alignment for enhanced mechanical properties.

- Flash Control: Automated trimming removes excess material while maintaining ≤5% scrap rate, followed by non-destructive testing for dimensional compliance.

- Heat Treatment: T6 tempering process (solution heat treatment + artificial aging) enhances yield strength by 20-30% while maintaining ductility.

- Surface Engineering: Standard finishing options include anodizing (MIL-STD-171), mechanical polishing (Ra≤3.2μm), or protective coatings for application-specific performance.

Aluminum Forging Advantages

| Factor | Forging | Casting | Machining |

|---|---|---|---|

| Strength | ★★★★★ | ★★☆ | ★★★☆ |

| Tolerance | ±0.1mm | ±0.5mm | ±0.05mm |

| Lead Time | 4-6 Weeks | 2-4 Weeks | 1-3 Weeks |

Design Challenges and Solutions

| Limitation | Engineering Solution |

|---|---|

| High Tooling Cost | Shared tooling program |

| Complex Geometry | Hybrid forging+CNC |

| Thin Walls | Multi-stage forging |

| Lead Time | Rapid tooling service |

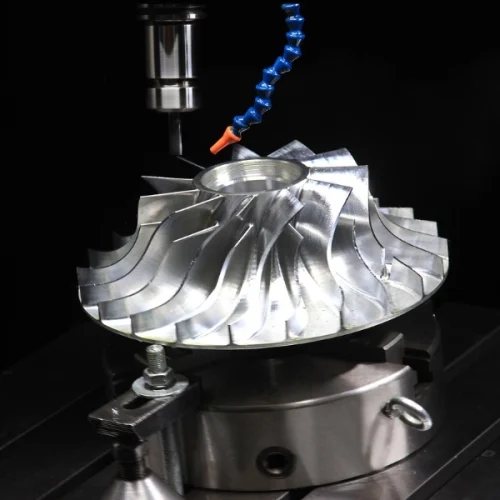

Engineered Aluminum Forgings Powering Modern Industries

Explore the diverse applications of aluminum die forging in multiple sectors.

Automotive Industry

Core Components

• Suspension control arms • EV battery trays • Turbocharger housings

Technical Value

40% weight reduction vs steel | ±0.2mm dimensional stability

Material Standards

AMS 4117 | ASTM B247

Aerospace Industry

Critical Parts

• Wing spars • Engine mounts • Flight control linkages

Performance Benchmark

7075-T6 @503MPa UTS | AMS 4037 compliance

Testing Protocols

NASM 1312-7 fastener testing

Energy Industry

Core Applications

• Wind turbine hubs • Solar tracker joints • Nuclear fixtures

Corrosion Resistance

ASTM B928 compliance | 1000hr salt spray tested

Environmental Ratings

NORSOK M-501 certified coatings

Electronics Industry

Precision Solutions

• 5G base station heat spreaders • Server cold plates • IGBT modules

Thermal Performance

205 W/m·K conductivity | Ra1.6μm surface finish

Industry Certifications

IPC-6012 packaging standards

Marine Industry

Critical Components

• Hull reinforcements • Propulsion shafts • Deck machinery

Marine Durability

ASTM G85 compliant | 30% weight reduction

Medical Industry

High-Precision Assemblies

• MRI components • Surgical robotics • Sterilization vessels

Surface Requirements

Ra0.8μm medical-grade polish | ISO 13485 compliance

Precision of Aluminum Forging

Understand the high precision achievable with aluminum die forging technology.

| Parameter | Precision Level | Description |

|---|---|---|

| Dimensional Tolerance | ±0.1 mm to ±0.5 mm | High dimensional accuracy for critical components |

| Surface Finish | 3.2 to 6.3 µm Ra | Smooth surface finish reducing the need for additional machining |

| Weight Tolerance | ±1% to ±5% | Consistent weight control for uniformity across parts |

| Geometric Tolerance | ±0.5° to ±2° | Precise control over angles and shapes |

| Roundness | 0.05 mm to 0.1 mm | Accurate roundness for cylindrical parts |

| Flatness | 0.05 mm per 25 mm | Ensuring flat surfaces meet stringent requirements |

| Parallelism | 0.1 mm per 100 mm | Maintaining parallelism in forged parts |

FAQ About HDC Custom Aluminum Die Forging Service

Find answers to common questions about our custom aluminum die forging services.

The lead time typically ranges from 4 to 8 weeks, depending on the complexity and quantity of the order. We strive to meet your deadlines and will provide an estimated timeline during the consultation.

Yes, our experienced engineering team can assist with the design and optimization of your forged parts to ensure they meet your specifications and performance requirements.

We accommodate both small and large orders. The minimum order quantity is usually 200 pieces, but we are flexible and can discuss your specific needs. There is no maximum order quantity; we can handle large-scale production runs.

We offer a wide range of aluminum alloys, including 6061, 7075, 2024, 5083, and 6082. Our team can help you select the best alloy for your application based on strength, corrosion resistance, and other factors.

We have a rigorous quality control process that includes material inspection, dimensional verification, and mechanical testing. Our quality assurance team ensures that every part meets industry standards and your specific requirements.

Yes, we offer comprehensive services including CNC machining, heat treatment, surface finishing, and assembly to provide you with a complete, ready-to-use product.

Absolutely. We can create prototypes to validate the design and functionality of your part before moving into full-scale production. This helps to ensure the final product meets your expectations.

We serve a variety of industries including automotive, aerospace, industrial machinery, construction, marine, and electronics. Our versatile capabilities allow us to meet the unique needs of each sector.

Get an Instant Quote!

Get a quick quote for your project with just a click! Request an instant quote now!

Contact With Us

for any inquiry