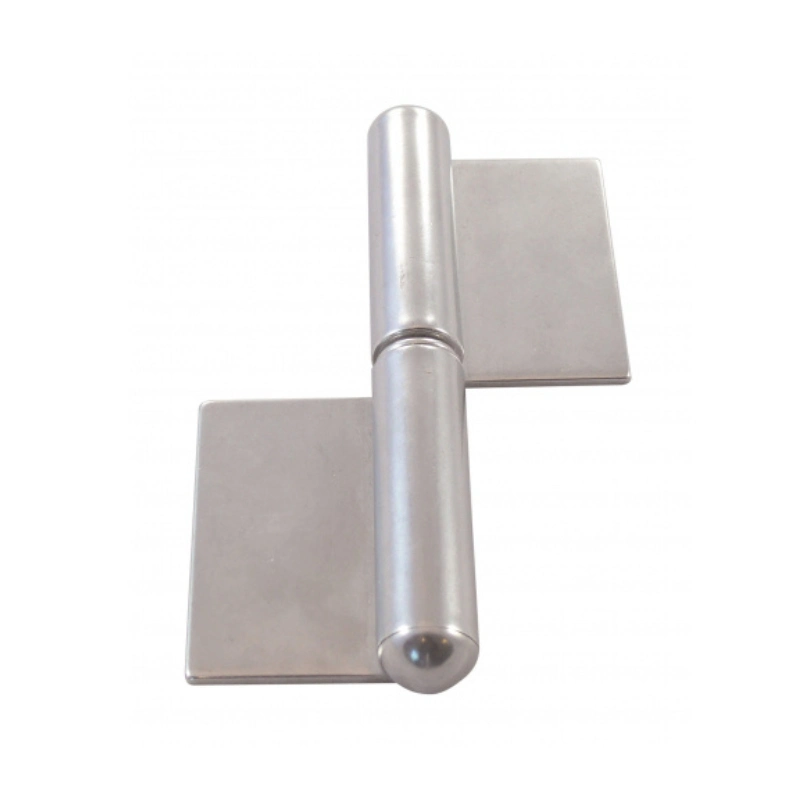

Heavy Duty Aluminum Weld-on Hinge with Stainless Steel Pin&Bushing and Brass Grease Fitting

Reference FOB Price:

US $1.50-9.00

/Piece | 500 Pieces (Min Order.)

Type:

Bullet Hinge

Samples:

US$ 30/Piece

Customization:

Available

Shipping Cost:

Negotiate with us about Details.

Payment Method:

Product Details

Basic Info

| Model NO. | HDCTWBH001 |

| Style | Weld-On Bullet Hinge |

| Material | Aluminum Alloy |

| Finish Type | Plain |

| Available Size |

|

| MOQ | 500 Pcs |

| Custom Logo | / |

| Origin | China |

Packaging & Delivery | |

| Shipping Option | Courier, Air, Sea, Railway Express, EXW, FOB, CIF, DDU, DDP |

| Delivery Date | 25-30 days |

| Transport Package | Customized, Carton, Pallet |

Custom Options

| Size | Custom dimensions |

| Material Grade | 6061, 7075, 5052, etc. |

| Finish | Natural, Polished, Brushed |

| Pivot Mechanism | Standard, Greased, Sealed Bearings |

| Custom Marking | Text, Logos, Patterns |

Check out our Customization Support & Service Policy for detailed information on our customization services, including design, prototyping, and payment options.

Key Features

- Application: Suitable for aluminum doors in residential, commercial, industrial, and vehicle applications

- Material: Corrosion-resistant aluminum alloy

- Finish: Metal’s natural color, with no additional coating

- Features: Streamlined bullet shape for wear-free rotation and smooth opening and closing

- Installation: Designed for weld-on application to ensure a secure attachment to the door

- Durability: Highly weather-resistant for use in various climatic conditions

- Place of Origin: Wuxi, China

- Brand Name: HDC