- بيت

- Capabilities

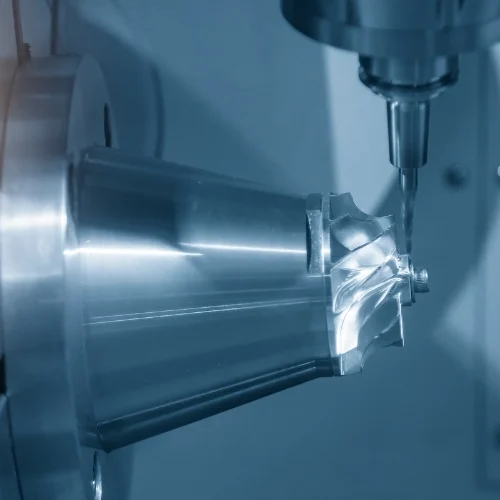

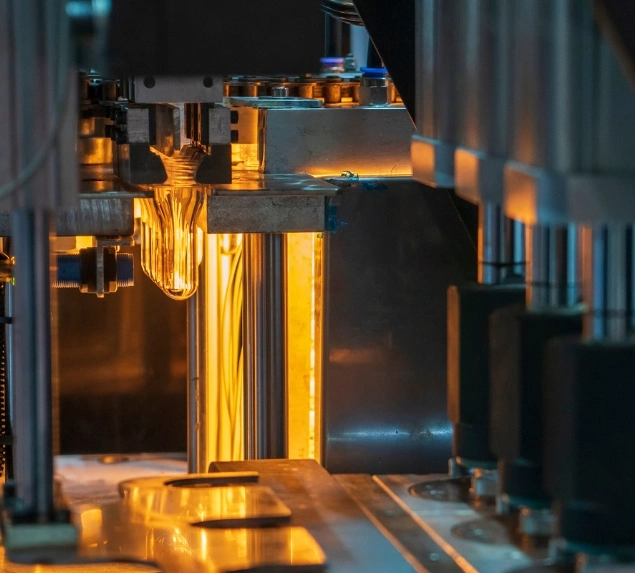

- Plastic Blow Molding

Professional Custom Plastic Blow Molding Services

HDC Manufacturing delivers exceptional custom plastic blow molding services for small batch production and large-scale manufacturing. With advanced technology and a professional team, we provide high-quality, precision products to help your business stand out in the market.

Benefits of Plastic Blow Molding

Discover the numerous advantages of plastic blow molding to enhance your product development.

Efficient Production

Design Flexibility

Cost Efficiency

Lightweight Products

High Durability

Consistency and Precision

Why Choose HDC Plastic Blow Molding Service

Cutting-Edge Technology

Comprehensive Services

Rigorous Quality Control

Competitive Pricing

Sustainability Commitment

Customer-Centric Approach

Materials HDC Offers for Blow Molding

Versatile and High-Quality Material Options Tailored to Your Specific Requirements

Polyethylene (PE)

Exceptional durability, flexibility, and chemical resistance.

Polypropylene (PP)

Excellent stiffness, heat resistance, and chemical resistance.

Polyethylene Terephthalate (PET)

High strength, clarity, and excellent barrier properties.

Polyvinyl Chloride (PVC)

High strength, abrasion resistance, and chemical resistance.

Acrylonitrile Butadiene Styrene (ABS)

Combines strength, toughness, and rigidity.

High-Density Polyethylene (HDPE)

Excellent impact resistance, strength, and environmental stress crack resistance.

Understanding Plastic Blow Molding

Explore the technology, applications, and innovations of plastic blow molding, a versatile manufacturing process for creating hollow plastic parts.

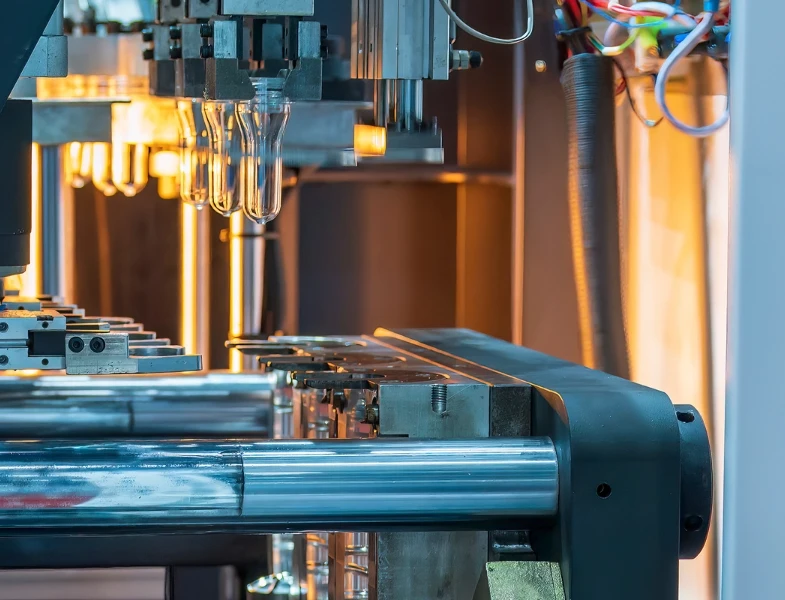

What is Plastic Blow Molding?

Plastic blow molding is a manufacturing process used to create hollow plastic parts by inflating a heated plastic tube until it fills a mold and forms the desired shape. Developed in the 1930s, this technique has evolved significantly and is now a cornerstone of modern manufacturing.

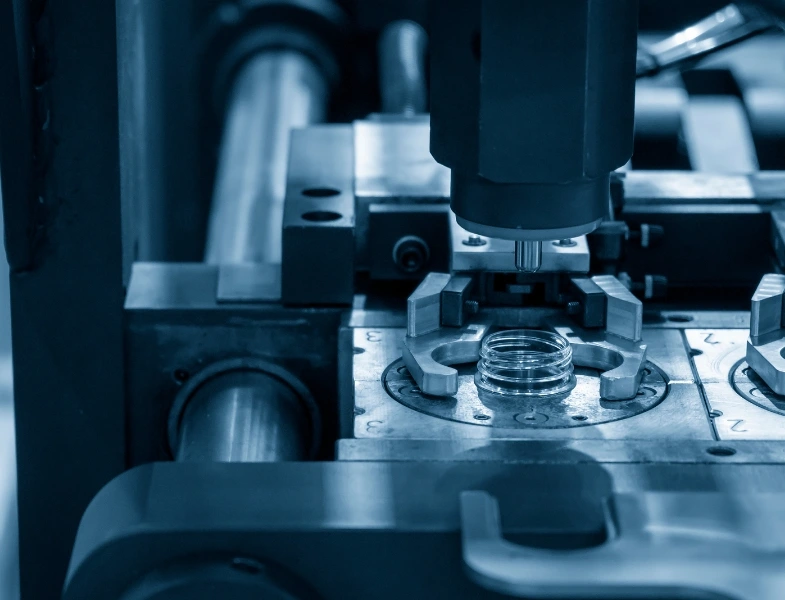

Key Features of Blow Molding

- Tight Tolerances: Typically within ±0.25% to ±1% of specified dimensions.

- Consistency: Ensures uniform quality across large production runs.

- High-Volume Output: Ideal for mass production needs.

- Automation: Modern systems enhance efficiency and quality control.

Challenges and Solutions

1. Uniform Wall Thickness

- Challenge: Maintaining consistent thickness in complex designs.

- Solution: Advanced mold design and real-time monitoring systems.

2. Complex Shapes

- Challenge: Producing intricate geometries.

- Solution: Innovations in mold cooling and material flow control.

3. Material Shrinkage

- Challenge: Managing shrinkage during cooling.

- Solution: Optimized cooling technologies and material selection.

Applications of Blow Molding Across Various Industries

Exploring the Versatile Uses of Blow Molding Technology in Different Sectors

Automotive Industry

Food Industry

Medical Industry

Industrial Applications

Consumer Goods

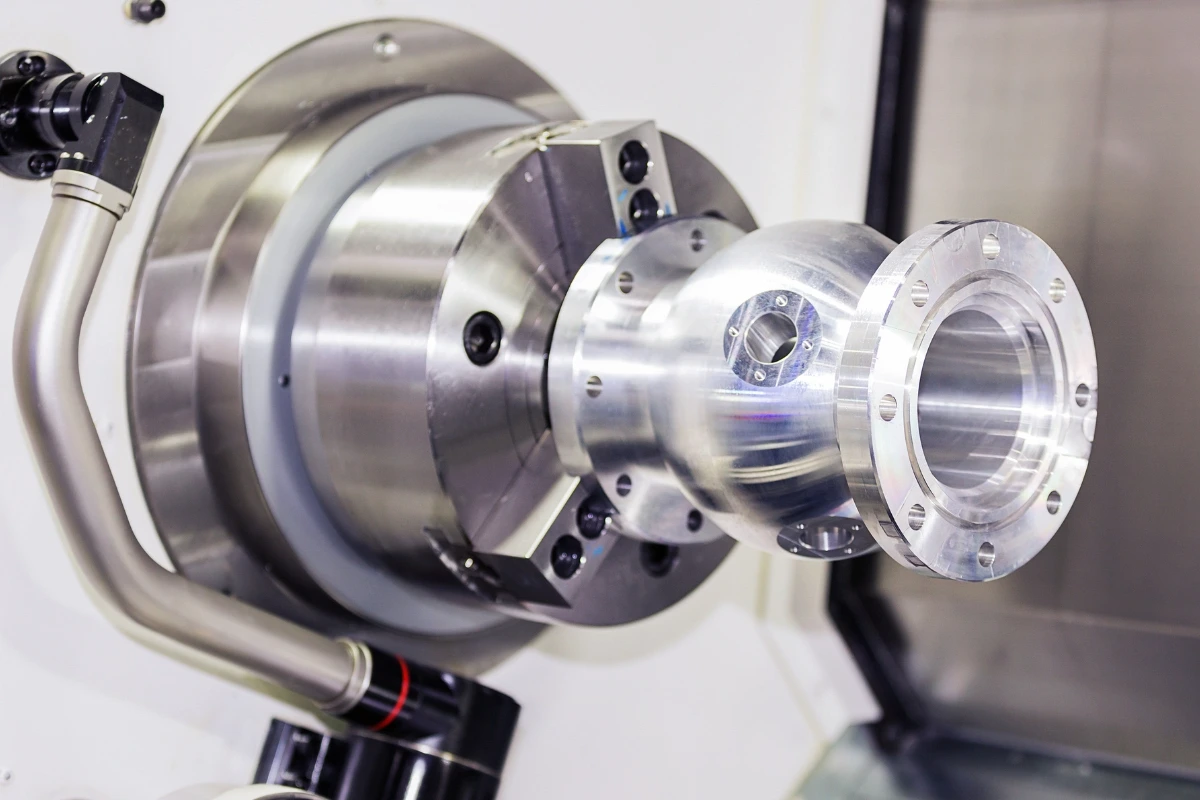

Precision in Blow Molding

Blow molding technology achieves high precision, ensuring each product meets strict dimensional and quality standards.

| Parameter | Typical Precision |

| Dimensional Tolerance | ±0.25% to ±1% |

| Wall Thickness | ±0.1 mm to ±0.5 mm |

| Weight Variation | ±1% to ±5% |

| Surface Finish | Ra 0.8 to Ra 1.6 μm |

| Roundness | ±0.5% |

| Concentricity | ±0.5% |

Blow Molding Technical Specifications

| Specification | Details |

| Wall Thickness Range | 0.5 mm to 2 mm |

| Material Compatibility | PE, PP, PET, PVC, ABS, HDPE |

| Mold Clamping Force | Up to 500 kN |

| Blow Pressure | 2 to 6 bar |

| Production Speed | Up to 1500 units per hour (varies with product size) |

| Tolerance | Dimensional tolerance: ±0.25% to ±1% |

| Surface Finish | Ra 0.8 to Ra 1.6 μm |

| Automation Level | Fully automated with real-time monitoring and control |

| Max Part Size | Up to 1 meter in length and 0.7 meters in diameter |

FAQs About HDC Plastic Blow Molding Service

Find answers to common questions about HDC’s plastic blow molding services, from customization to quality assurance, and ensure your project meets exact specifications.

We work with a wide range of materials including PE, PP, PET, PVC, ABS, and HDPE. Each material offers unique properties suited for different applications, ensuring we can meet your specific needs.

The lead time varies depending on the complexity and volume of the order. Typically, it ranges from 6 to 8 weeks from the finalization of the design to the completion of production.

We offer assistance with design and prototyping, but we require customers to provide detailed drawings or samples. While we can guide and support the design process, understanding your specific needs fully necessitates your input and initial designs.

We can produce products up to 1 meter in length and 0.7 meters in diameter.

We implement rigorous quality control measures at every stage of production, including real-time monitoring, precise dimensional checks, and thorough inspections to ensure each product meets our high standards.

While blow molding is highly versatile and can create complex shapes, there are some limitations with extremely intricate designs and very small details. Our team can help optimize your design for the best results.

Costs vary based on material, complexity, size, and volume of the order. We provide competitive pricing and will work with you to find cost-effective solutions that meet your budget.

Get an Instant Quote!

Get a quick quote for your project with just a click! Request an instant quote now!

Contact With Us

for any inquiry