- Home

- Capabilities

- CNC Milling Service

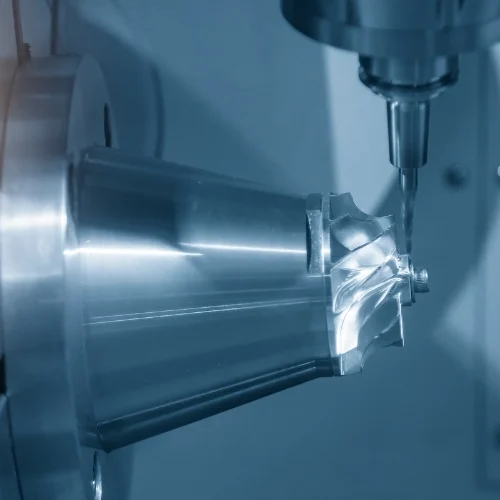

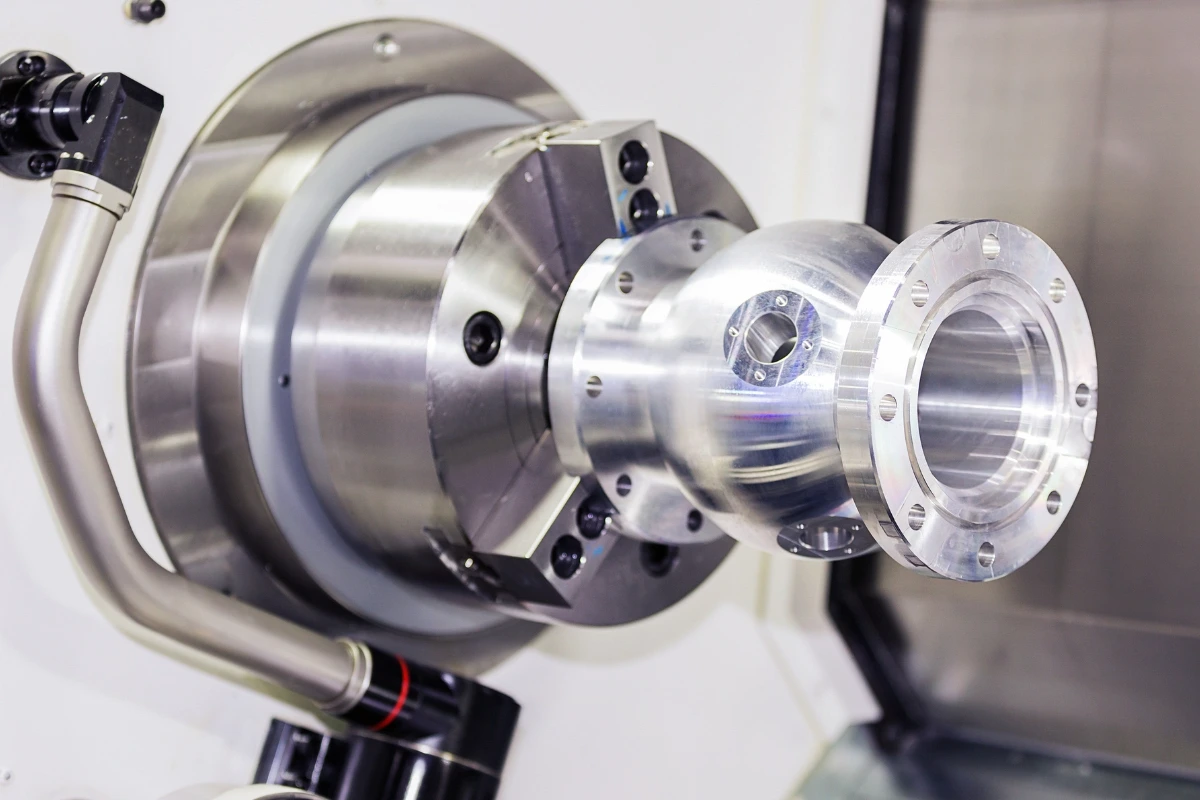

CNC Milling Service Provided By HDC

Discover how HDC leverages state-of-the-art CNC milling technology to produce precision parts that meet the highest standards of quality and performance.

Benefits of CNC Milling

Explore the key advantages of CNC milling, from high precision and repeatability to flexibility in manufacturing complex parts.

Why Choose HDC CNC Milling

- Advanced Equipment: We operate state-of-the-art CNC milling machines, including both four-axis and five-axis machining centers, enabling us to handle complex and precise manufacturing tasks.

- Experienced Team: Our team consists of highly experienced designers and operators who bring expertise and meticulous attention to every project, ensuring top-quality results.

- Quality Assurance: With rigorous quality control measures in place, we guarantee that all parts meet the highest standards of precision and performance.

- Comprehensive Support: We provide full-scale support to our clients, from initial design consultation to final production, ensuring a seamless manufacturing process.

- Tailored Solutions: Our ability to customize services according to client needs makes us a versatile partner in CNC milling, capable of adapting to diverse industry requirements.

- Reliability and Efficiency: We are committed to delivering projects on time and within budget, making us a reliable choice for businesses looking for efficient and effective CNC milling solutions.

Materials We Provides For CNC Milling

Explore the wide range of high-quality materials provided by HDC for CNC milling, including stainless steel, aluminum alloys, and more, tailored to enhance your manufacturing needs.

HDC provides a range of certified stainless steel materials, including 304, 316L, and 410, which offer excellent corrosion resistance and strength, making them ideal for parts exposed to harsh environments.

HDC offers lightweight and easily machinable aluminum alloys such as 6061, 7075, and 2024, perfect for aerospace and automotive applications where weight reduction is crucial.

HDC supplies various grades of carbon steel including A36, 1018, and 1045, known for their robust strength and impact resistance, suitable for creating durable components.

HDC provides versatile polymeric materials like Nylon, ABS, and Polycarbonate, enabling the production of complex, lightweight parts that are tailored for specific applications.

HDC offers high-performance titanium alloys such as Grade 5 (Ti6Al4V) and Grade 2, which are highly valued for their superior strength-to-weight ratio and excellent corrosion resistance, essential in aerospace and medical sectors.

HDC supplies a variety of copper alloys, including C110, Brass, and Bronze, renowned for their outstanding electrical and thermal conductivity, ideal for electrical components.

Deep Dive into CNC Milling

Explore why CNC milling is a critical manufacturing technique, its unique

capabilities, suitable applications, and the latest advancements.

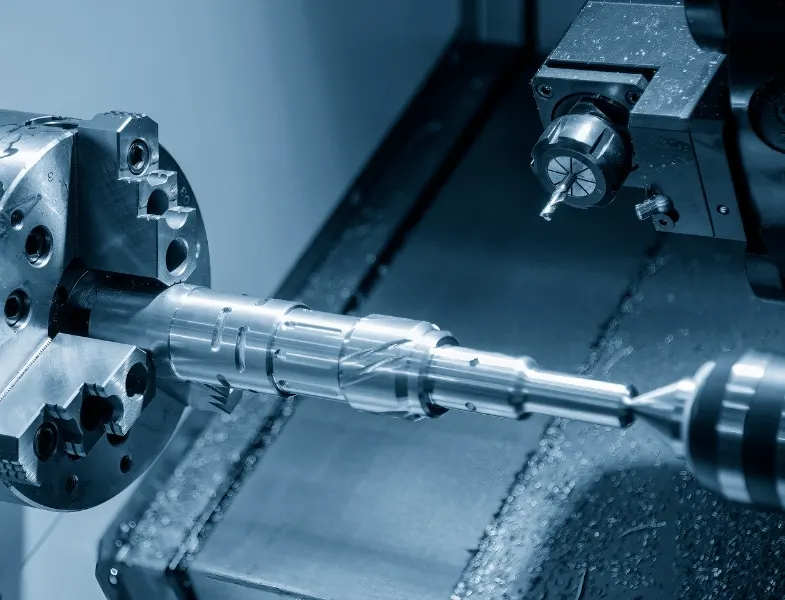

CNC Milling, named for the “milling” process, involves the use of rotary cutting tools to remove material from a workpiece, achieving precise shapes and features. Here’s a closer look at the specifics of CNC milling:

- Why “Milling”?: The term “milling” refers to the process of grinding or cutting material with a rotating tool, which differs from turning where the part is rotated. In milling, the tool rotates at high speeds to cut materials into the desired form and dimensions.

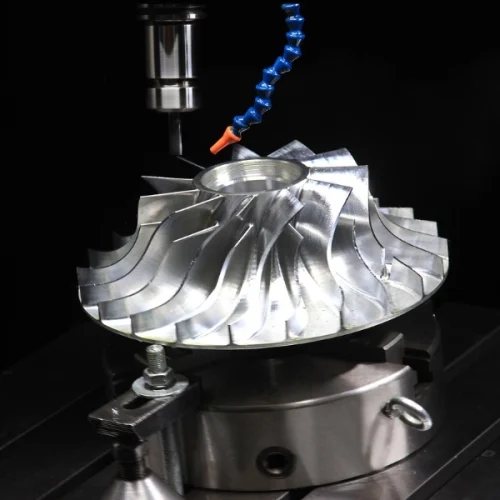

- Characteristics of Milling: CNC milling machines can operate on multiple axes (3-axis, 4-axis, or 5-axis mills), providing versatility to create complex geometries and deep cuts with high precision. The multi-axis setup allows the machine to move the tool in various directions, offering detailed and intricate machining capabilities.

- Suitable Shapes and Parts: This process is ideal for producing parts with detailed features such as slots, holes, notches, and contours. CNC milling is highly effective for functional prototypes, engine components, and complex mechanisms, which require precise and repeatable cuts.

- Limitations: Despite its capabilities, CNC milling has limitations, including the initial setup cost, which can be high. The process also requires expert programming and operation to maximize efficiency and quality. Additionally, the geometry of a part may limit tool access, making certain areas challenging to machine.

- Recent Developments: Advances in CNC technology include improvements in software algorithms that enhance tool paths for faster and more efficient milling. There is also a growing integration of automation and AI to optimize the milling process further, reducing waste and increasing production speeds.

Applications of CNC Milling Across Industries

Explore how CNC milling shapes critical components in various sectors, driving innovation and precision in manufacturing.

Automotive Industry

Aerospace Industry

Medical Industry

Electronics Industry

Defense Industry

Prototyping

Precision Capabilities of CNC Milling

Discover the exceptional precision that CNC milling can achieve, ensuring parts meet exact specifications for diverse applications.

| Feature | Typical Tolerance | Description |

|---|---|---|

| General Dimension | ±0.005 inches | Standard tolerance for general features in most milling operations. |

| Critical Dimension | ±0.0005 inches | Higher precision for critical dimensions in specialized applications. |

| Surface Finish | 16-125 microinches | Indicates the surface roughness achievable with standard milling tools. |

| Hole Diameter | ±0.001 inches | Precision for hole diameters, important in high-requirement fittings. |

| Positional Accuracy | ±0.0002 inches | Alignment accuracy of features relative to each other on a part. |

Get an Instant Quote!

Get a quick quote for your project with just a click! Request an instant quote now!

Contact With Us

for any inquiry