Im Folgenden sind die zehn größten Schmiedeunternehmen für Aluminiumlegierungen aufgeführt …

Feinguss-Service für Präzisionstechnik

Feinguss-Service aus einer Hand – von Design, Fertigung und Endbearbeitung bis hin zum Versand. Wir liefern Präzisionsgussteile an Kunden weltweit.

• ISO-zertifiziert

• Komplettlösung

• Konkurrenzfähiger Preis

Feinguss-Dienstleistungen

Führende Feingussgießerei in China, die Gusslösungen für komplexe und präzise Komponenten liefert.

Vakuumfeinguss

Das Gießen in einer sauerstofffreien Umgebung führt zu Gussteilen mit hoher Präzision und Qualität.

- Vakuumumgebung verhindert Defekte

- Saubere und glatte Oberflächenbeschaffenheit

- Hohe Maßgenauigkeit

- Geeignet für komplexe Dünnwandstrukturen

Lern mehr

Feinguss aus Superlegierungen

Mit Superlegierungen gegossen, hochfeste Gussteile für anspruchsvolle Anwendungen gebaut.

- Materialspektrum: Inconel, Hastelloy, etc.

- Geeignet für hohe Temperaturen und korrosive Umgebungen

- Perfekt für Turbinen- und Motorkomponenten

Lern mehr

Wärmebehandlung

Präzise Kontrolle von Temperatur und Abkühlgeschwindigkeit verbessert die Gussleistung und eliminiert Defekte

- Prozesse: Glühen, Normalisieren, Abschrecken und Anlassen

- Beseitigt Gussspannungen, stabilisiert Abmessungen und Form und verbessert die mechanischen Eigenschaften

Lern mehr

Materialien und Oberflächen

Über 30 Metallmaterialien sind in HDC verfügbar, um die Anforderungen in verschiedenen Anwendungen zu erfüllen

Oberflächenbehandlung

Sand-/Perlstrahlen

Entfernt Oberflächenablagerungen, Rost und Rückstände und sorgt für ein gleichmäßiges mattes oder satiniertes Finish

Mechanisches Polieren

Entfernen Sie Grate und Grate für eine gleichmäßige, glatte und hochglänzende Oberfläche

Galvanik

Verbessern Sie die Verschleiß- und Korrosionsbeständigkeit durch Chrom- oder Nickelbeschichtungen

Pulverbeschichtung

Die Balance zwischen Umweltfreundlichkeit und herausragender Beschichtungsleistung

Malerei

Reichhaltige Farboptionen, verbesserte Korrosionsbeständigkeit

Benötigt man ein anderes Material oder eine andere Verarbeitung?

Finden Sie Ihre gewünschten Optionen nicht in der obigen Liste? Kein Problem! Die Möglichkeiten von HDC gehen über die Standardoptionen hinaus. Bitte kontaktieren Sie uns für Ihre speziellen Material- und Oberflächenanforderungen.

Von uns bediente Branchen

Vielfältige Feingusslösungen für unterschiedliche Branchen mit unserer über 15-jährigen Expertise

Luft- und Raumfahrt

Turbinenschaufeln, DüsenleitschaufelnAutomobil

Turbolader, Getriebekomponenten, HalterungenMedizinisch

Chirurgische Instrumente, Zahnimplantate, orthopädische GeräteEnergie

Turbinenkomponenten, Ventilkörper, PumpengehäuseIndustrie

Ventilkörper, Pumpenkomponenten, Maschinenteile

Strenge Qualitätskontrolle

Unsere Qualitätskontrolle umfasst den gesamten Gussprozess, vom Material bis zum Endprodukt, und stellt sicher, dass jedes Produkt Ihren Erwartungen entspricht.

Zertifizierungen:

✓ ISO 9001:2015

✓ ISO 14001:2015

✓ AS9100

Materialzusammensetzung Analysieren

Analysieren Sie die chemische Zusammensetzung des Rohmaterials mit einem Spektrometer

Mechanische Leistungsprüfung

Härte- und Zugfestigkeitsprüfungen, um sicherzustellen, dass die mechanischen Eigenschaften den Normen entsprechen

Gießprozesssteuerung

Überwacht wichtige Parameter während des gesamten Feingussprozesses, um eine gleichbleibende Qualität sicherzustellen

Fluoreszierende Eindringprüfung

Erkennt Defekte in Gussteilen mithilfe eines fluoreszierenden Farbstoffs und ultraviolettem Licht zur hochempfindlichen Fehleridentifizierung

Warum HDC wählen

Wir liefern außergewöhnliche Gussteile durch kundenspezifische Lösungen und Präzisionsfertigung

Komplettlösung

- End-to-End-Lösungen vom Entwurf bis zur Lieferung

- Integrierte interne Kapazitäten (Werkzeugbau, Gießen, Endbearbeitung, Qualitätssicherung)

Umfangreiche Anpassungsoptionen

- Über 30 Materialien und Oberflächen verfügbar

- Maßgeschneiderte Legierung für spezielle Anwendungen

- Projektspezifische Prozessoptimierung

Weltweiter Service

- Kompilieren nach internationalen Qualitätsstandards

- Mehrsprachiger technischer Support

- Lokale Compliance-Expertise

Wettbewerbsfähige Preisanpassung

- Kontinuierliche Optimierung des Gießprozesses zur Senkung der Fehlerquote

- Nutzen Sie ausgereifte Lieferketten für kosteneffiziente Beschaffung

Mehr über HDC

Sehen Sie sich unsere Anlagen- und Ausrüstungsliste an und erfahren Sie mehr über die Casting-Kapazitäten von HDC

| Ausrüstung | Spezifikationen | Menge |

| Wachsinjektionsmaschinen | – | 5 |

| Vakuumschmelzöfen | 50 kg, 100 kg Kapazität | 2 |

| Mittelfrequenz-Induktionsöfen | 250 kg (2 Einheiten), 100 kg (1 Einheit) | 3 |

| Schalenbacköfen | – | 2 |

| Wärmebehandlungsöfen | – | 2 |

| Strahlanlagen | – | 5 |

| Sandstrahlmaschinen | – | 2 |

| Spektrometer | SPECTRO Deutschland, 5. Generation Direktablesung | 1 |

| Zugprüfmaschine | – | 1 |

| Stromversorgungssystem | 630 kVA Kastentransformatoren | 2 |

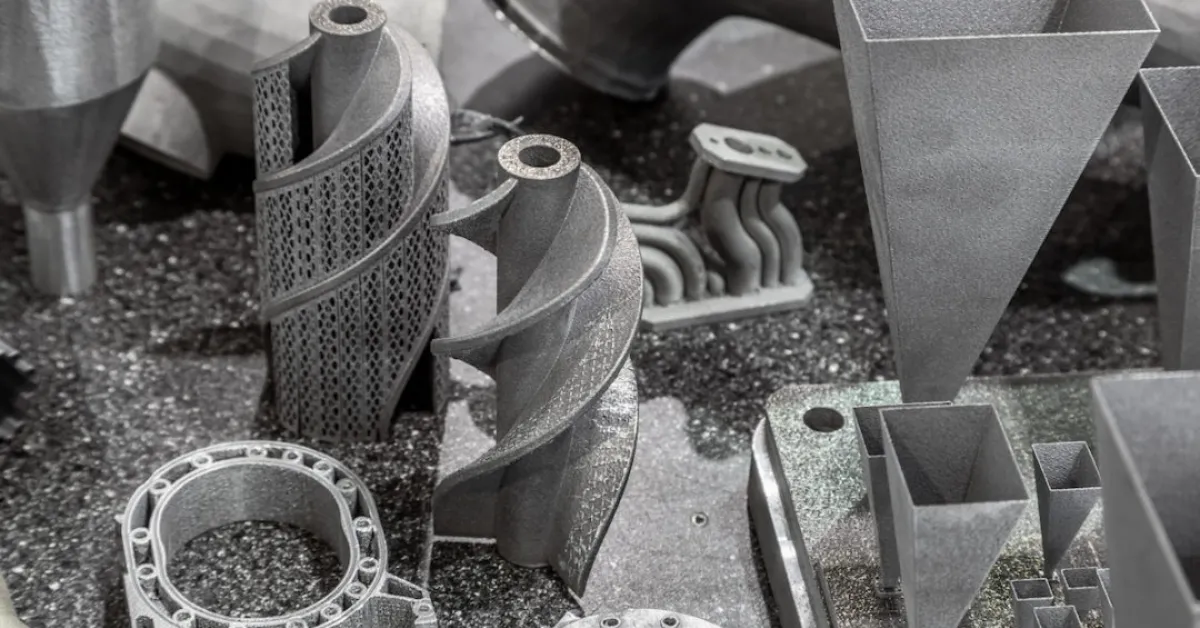

Was ist Feinguss

Feinguss ist ein Präzisionsgussverfahren, auch bekannt als „Wachsausschmelzverfahren“. Es zeichnet sich durch die Herstellung von Metallgussteilen mit extrem komplexen Formen, hoher Maßgenauigkeit und guter Oberflächengüte aus, insbesondere bei hochschmelzenden Legierungen oder komplexen Teilen, die mit anderen Verfahren nur schwer zu bearbeiten sind.

Der Prozess des Feingusses

Der Hauptprozess des Feingusses kann in die folgenden sechs Schritte unterteilt werden:

- Wachsmodellherstellung: Erstellen Sie eine Metallform basierend auf der endgültigen Form des Teils und spritzen Sie dann niedrigschmelzendes Wachs unter Druck in die Form, um ein präzises Wachsmuster zu erhalten.

- Rohbau (Investment): Das Wachsmodell wird wiederholt in die Keramikaufschlämmung eingetaucht, und nach jedem Eintauchen wird eine Schicht feinen Sandes aus feuerfestem Material aufgestreut, und dieser Vorgang wird mehrmals wiederholt, bis sich auf der Oberfläche der Wachsform eine Keramikschale mit ausreichender Dicke (normalerweise 5-15 mm) und ausreichender Festigkeit gebildet hat

- Entwachsen (Entwachsung / Wachsausschmelzverfahren): Nachdem die Keramikschale getrocknet und ausgehärtet ist, wird sie in einen Hochtemperaturdampfofen gelegt, damit die Wachsform im Inneren schmilzt und herausfließt, was auch der Ursprung des Namens „Wachsausschmelzverfahren“ ist.

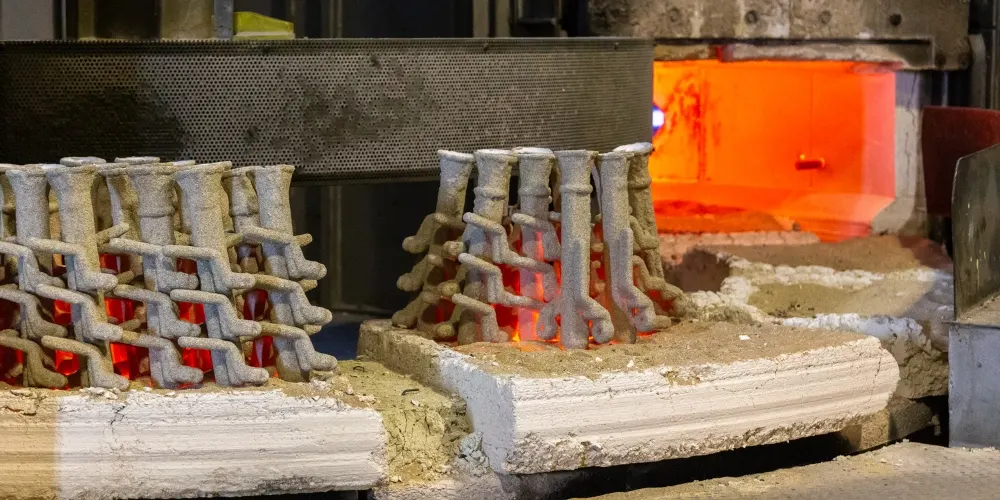

- Schalensintern: Legen Sie die entwachste Keramikschale zum Brennen in einen Hochtemperaturofen, um ihre Festigkeit zu erhöhen.

- Casting: Gießen Sie das geschmolzene Metall in den Hohlraum der Schalenform.

- Schalenentfernung und Nachbearbeitung: Nachdem das Metall vollständig ausgehärtet ist, wird die äußere Schicht der Keramikschale durch mechanische Vibration, Sandstrahlen usw. entfernt. Anschließend wird das Angussloch abgeschnitten und nachfolgende Prozesse wie Wärmebehandlung, Sandstrahlen, Polieren, Bearbeiten und Oberflächenbehandlung werden nach Bedarf durchgeführt.

Feingussfluss

Nachfolgend finden Sie unseren umfassenden Prozessablauf beim Feingießen

FAQ

Antworten auf häufig gestellte Fragen zu unserem Feinguss-Service

Ja, mit unseren erfahrenen Ingenieuren und unseren hauseigenen CNC-Bearbeitungskapazitäten können wir Formen entwerfen und herstellen und so schnelle Unterstützung bei Designänderungen bieten.

Ja, wir bieten skalierbare Produktionsdienstleistungen, vom Prototyp bis zur Massenproduktion von über 2.000 Einheiten pro Monat. HDC kann alle Ihre Anforderungen erfüllen.

Ja, wir stellen Prototypen zur Qualitätsüberprüfung und für Funktionsanpassungstests vor der Massenproduktion bereit.

Wir können Teile mit einem Gewicht von 0,1 kg bis 100 kg und einer Größe von 500 mm x 500 mm x 500 mm gießen.

Ja, wir bieten einen Kundendienst an und sind für Qualitätsprobleme verantwortlich, die durch den Herstellungsprozess und das Material verursacht werden.

Wir bieten Luft-, See- und Schienentransporte sowie Expresslieferungen an. Sollten Sie andere Anforderungen haben, kontaktieren Sie uns bitte für weitere Informationen.

Kostenloses Angebot einholen

Möchten Sie Ihre Anforderungen besprechen? Unser Engineering-Team steht Ihnen mit kompetenter Beratung und wettbewerbsfähigen Preisen zur Verfügung.

Kostenloses Angebot anfordern

Verwandte Ressourcen

Gesenkschmieden vs. Freiformschmieden

Gesenkschmieden vs. Freiformschmieden sind Metallschmiedeverfahren ...

Vergleich von Metall-3D-Druck, Schmieden und Feinguss

Entdecken Sie die Unterschiede zwischen 3D-Metalldruck, Schmieden und Investitionen ...

Aluminiumschmieden: Herstellung von Haltbarkeit und Effizienz in allen Branchen

Das Schmieden von Aluminium ist ein wichtiger Bestandteil der modernen Fertigungsindustrie ...

Metallfeinguss vs. Metallschmieden: 8 Dinge, die Sie beachten sollten

Die Wahl zwischen Feinguss und Schmieden hängt von Ihren spezifischen Anforderungen ab.