OEM-Hersteller von Motorradschmiedeteilen in China

HDC verfügt über Schmiede- und CNC-Bearbeitungskenntnisse und fertigt hochwertige OEM- und Modifikations-Motorradteile für Motorradhersteller auf der ganzen Welt.

- Große Auswahl an Materialien

- Konkurrenzfähiger Preis

- ISO- und IATF-zertifizierte Fabrik

Warum Schmieden für Motorradteile?

Für Motorradteile, die auf hohe Leistung und ein außergewöhnliches Verhältnis von Festigkeit zu Gewicht abzielen, ist Schmieden die ideale Methode.

Leistung optimieren

Geschmiedete Aluminiumteile vereinen Stärke und Leichtigkeit und wurden für das Hochleistungsmodell entwickelt.

Konstante Qualität

Sobald eine Form gebaut ist, können Sie konstant hochwertige Produkte mit hoher Produktionsrate schmieden.

Kosteneffizient

Trotz der höheren Vorlaufkosten ist Schmieden in der Massenproduktion im Vergleich zu CNC und Guss weitaus kostengünstiger

Optimiert für Sicherheit

Geschmiedete Teile können hohen Belastungen und heftigen Stößen standhalten und sorgen so für Sicherheit bei Hochgeschwindigkeitsrennen.

Arten des Schmiedens von Motorradteilen

Etwa 801 unserer Schmiedeteile werden für den Motorsport hergestellt. Hier sind einige typische Teile, die wir für ein Motorrad herstellen.

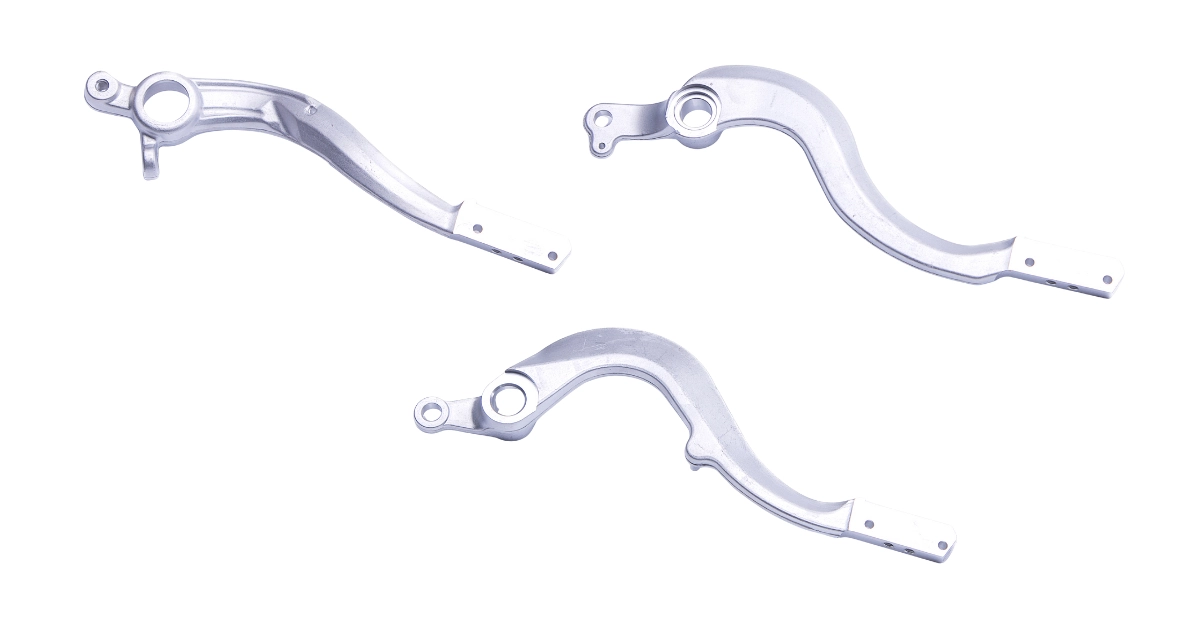

Steuerung & Bedienung

Lenker, Bremsgriff

Für Motorradteile mit komplexer Struktur und Kurven zur Umsetzung eines ergonomischen Designs ist das Gesenkschmieden ein sehr empfehlenswertes Verarbeitungsverfahren.

Da es sich um ein Near-Net-Shape-Verfahren handelt, können Sie die Nachbearbeitung reduzieren und gleichzeitig eine hohe Formpräzision beibehalten.

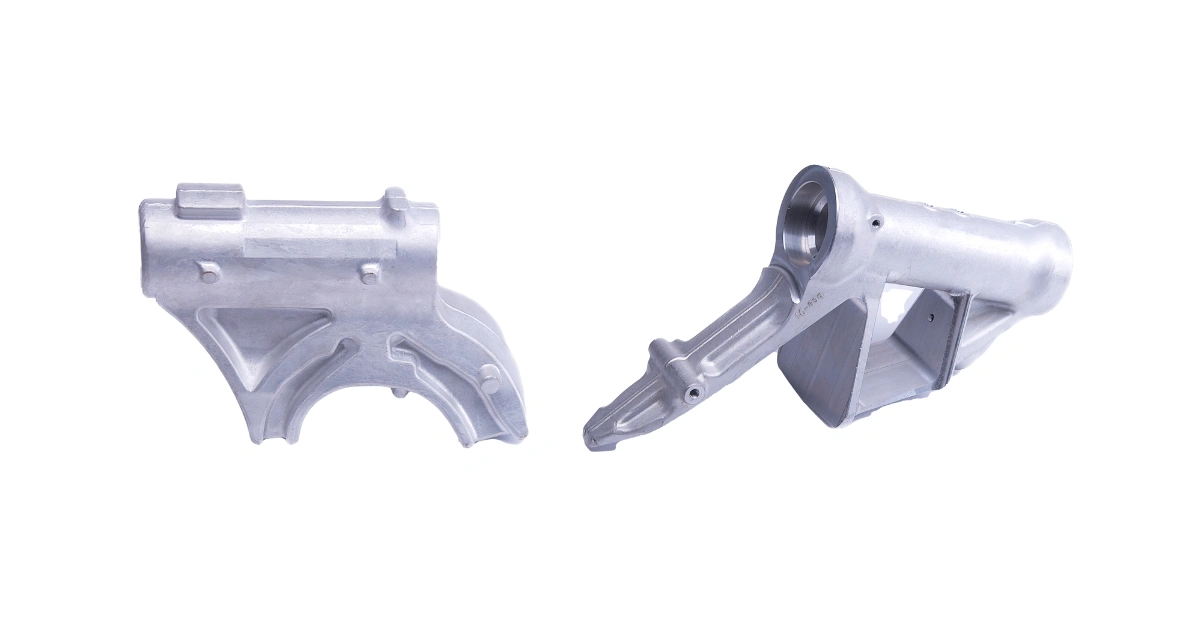

Bremsen & Getriebe

Radnabe, Bremskomponenten

Brems- und Getriebekomponenten sind für eine bessere Leistungsentfaltung unerlässlich. Bei HDC schmieden wir für eine solide, hochfeste Basis und führen anschließend CNC-Bearbeitung für kritische Abmessungen und Befestigungslöcher durch.

Gewährleistet eine reibungslose Übertragung und flexible Steuerung nach Belieben.

Struktur & Montage

Gabelbrücke, Karosserierahmen

Strukturen und Halterungen müssen sehr robust sein, um Stößen standzuhalten und ihre strukturelle Vollständigkeit und Zuverlässigkeit bei intensiven Rennen aufrechtzuerhalten.

HDC erfüllt alle Ihre Leistungsanforderungen durch Schmieden aus Aluminium in Luft- und Raumfahrtqualität und bietet erstklassige Produkte, die Ihnen einen Wettbewerbsvorteil verschaffen.

HDC – Komplettanbieter für Schmiedelösungen für Motorradteile

Als Metallverarbeitungsfabrik mit ISO- und IATF-Zertifizierung bietet HDC Ihnen eine Komplettlösung für die Herstellung von Motorradteilen.

Von DFM, Formenbau, Prototyping, Massenproduktion, Wärmebehandlung, CNC-Finishing bis hin zur Oberflächenbehandlung wickeln wir den gesamten Prozess mit unseren bemerkenswerten internen Bearbeitungskapazitäten und einer soliden Lieferkette ab, die wir in jahrelanger Arbeit aufgebaut haben.

Mit jahrelanger Erfahrung in der Motorsportbranche und über 500 Kunden weltweit versteht HDC genau, wonach Sie suchen und was Ihre Anliegen sind. Egal, ob es sich um Modifikationsteile in Kleinserie oder OEM-Teile in Massenproduktion handelt, HDC ist für Sie da – ohne Kompromisse bei der Qualität.

Materialien zum Schmieden von Motorradteilen

HDC kann über 40 Metallarten schmieden. Hier sind die am häufigsten verwendeten Materialien.

Aluminiumlegierung

Serie 2000

Serie 6000

Serie 7000

Größen- und Gewichtsbereich

0,1 kg

Mindestgewicht

30 kg

Max. Gewicht

±0,05 mm

Toleranz (nach der Bearbeitung)

Ra 1,6 ~ 3,2 μm

Oberflächenveredlung

Benötigen Sie maßgeschneiderte Motorradteile?

Unsere Ingenieure entwickeln kundenspezifische Teile für Motorsport, Dirtbikes und Rennsport. Kontaktieren Sie uns für technische Beratung oder ein individuelles Angebot.

FAQ

Unterstützen Sie Kleinbestellungen?

Ja. Kleinserienbestellungen werden für Muster, den Kundendienst oder Nischenmärkte angenommen. Die Mindestbestellmenge hängt von der Spezifikation ab. Bitte kontaktieren Sie uns für weitere Informationen.

Wie läuft der Anpassungsprozess ab?

Sie senden Spezifikationen oder Zeichnungen → Wir bestätigen die Details und erstellen ein Angebot → Muster- oder Serienproduktion → Inspektion und Versand.

Wie lange dauert es normalerweise?

Muster benötigen in der Regel 5–7 Tage. Großbestellungen dauern je nach Menge etwa 15–25 Tage. Sonderanfertigungen können zusätzliche Zeit in Anspruch nehmen.

Wie stellt HDC die Produktqualität sicher?

Wir verwenden geschmiedetes Aluminium in Luft- und Raumfahrtqualität, CNC-Bearbeitung und strenge Qualitätskontrollen, einschließlich Maßprüfungen, Gewindeprüfungen, Härtetests und Überprüfung der Eloxaldicke.

Wie versenden Sie Bestellungen?

Wir bieten Seefracht, Luftfracht und internationalen Kurierdienst an. Die Lieferung kann an größere Häfen oder an Ihre angegebene Adresse erfolgen.

Bieten Sie After-Sales-Support an?

Ja. Wir stehen hinter jeder Bestellung. Sollten Sie auf Qualitätsprobleme, falsche Spezifikationen oder Transportschäden stoßen, kontaktieren Sie uns bitte – wir kümmern uns umgehend darum.