Finishes Provide by HDC Manufacturing

Discover the diverse range of custom finishes HDC offers to enhance the durability, aesthetics, and performance of your precision components. Explore our advanced finishing techniques tailored to meet the unique requirements of various industries.

The Role of Finishes in Custom Part Manufacturing

Finishes are critical components of the manufacturing process, providing both protective and aesthetic enhancements to custom parts. Applied at the final stages of production, finishes improve the product’s appearance, making it more appealing to customers. But the benefits of finishes extend far beyond just good looks. They also play a vital role in enhancing the durability and performance of the parts, making them capable of withstanding harsh environments and prolonged use.

The primary functional benefits of applying finishes to custom parts include:

- Corrosion Resistance: Finishes form a barrier against environmental factors that can lead to corrosion, thus prolonging the lifespan of the part.

- Improved Wear Resistance: Certain finishes increase the surface hardness of the part, making it more resistant to wear and tear from physical contact.

- Aesthetic Enhancement: Finishes can be used to add color, gloss, or texture to parts, enhancing their visual appeal and aligning with brand aesthetics.

- Environmental Protection: By protecting the underlying material from harsh conditions, finishes help prevent material degradation and maintain the part’s integrity over time.

Each type of finish brings its own set of advantages, allowing manufacturers to select the one most suited to their specific needs, thereby ensuring that the final product not only meets but exceeds customer expectations.

Benefits of Our Finishing Services

HDC’s finishing services are highly customizable, allowing for solutions that are specifically tailored to meet the unique requirements and specifications of each customer’s project.

HDC employs state-of-the-art finishing techniques that ensure high-quality results. This includes advanced application methods that improve adhesion and longevity of the finish.

HDC commits to high standards of quality control throughout the finishing process, ensuring that each part meets or exceeds industry standards and client expectations.

With streamlined processes and expert handling, HDC offers efficient turnaround times on finishing services, helping clients meet their project timelines without compromising on quality.

HDC provides expert consultation as part of its finishing services, offering guidance on selecting the most appropriate finish based on the part’s application, durability requirements, and aesthetic preferences.

HDC offers a wide array of finishing options suitable for both metal and plastic components. We can tailor finishes to enhance durability, appearance, or function, meeting diverse project requirements effectively.

Finishes We Provide

Explore the range of finishes HDC offers to enhance and protect your custom parts with both functionality and flair.

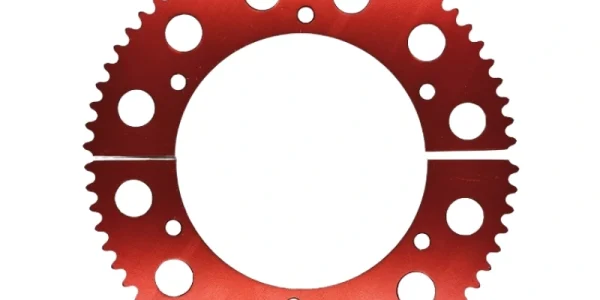

Powder Coating

This technique applies a dry powder that is cured under heat to create a hard layer. It offers enhanced durability and resistance to wear, making it suitable for metals where robust protection and aesthetics are desired.

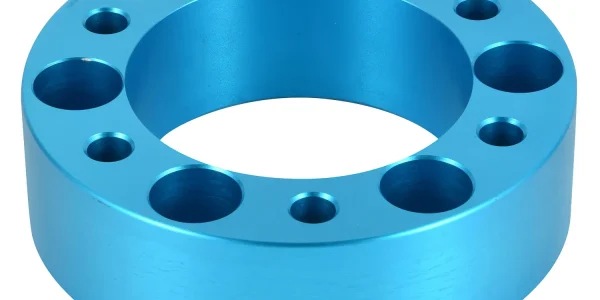

Anodizing

An electrochemical process that converts metal into a durable, corrosion-resistant anodic oxide finish, primarily used on aluminum to enhance its natural lustre and increase resistance to wear and weather.

Chrome Plating

Involves electroplating a thin layer of chromium onto a metal object. This finish is used on steel, copper, and brass for its ultra-shiny, aesthetically pleasing appearance and superb corrosion resistance.

Nickel Plating

This process deposits a layer of nickel onto a metal base, commonly used on steel, brass, and copper. It offers enhanced wear and corrosion resistance and adds a bright, reflective finish to the metal.

Zinc Plating

A popular choice for steel and iron, zinc plating involves applying a thin coating of zinc to the base metal to protect against rust. It’s especially valuable for its galvanic protection, prolonging the life of the metal even if the coating is breached.

Painting

Applying liquid paint and a topcoat to a metal surface for aesthetic purposes and to prevent corrosion. Suitable for virtually all metals, painting provides a cost-effective way to protect and beautify metal surfaces.

Polishing

This process creates a mirror-like finish on metals, enhancing both appearance and corrosion resistance. It’s ideal for decorative purposes and architectural details, providing a protective and attractive surface.

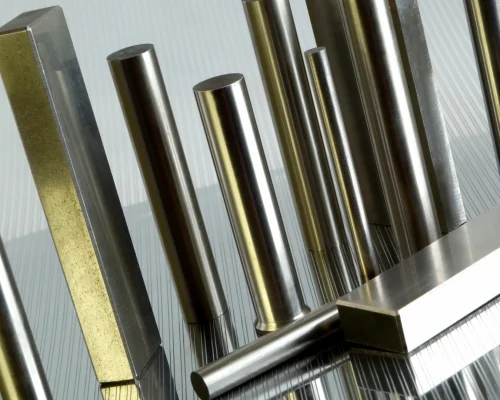

As Machined

This finish leaves parts with visible tool marks post-machining. It’s a basic, cost-effective option that provides functional surfaces without extra treatments, suitable for non-aesthetic , practical applications.

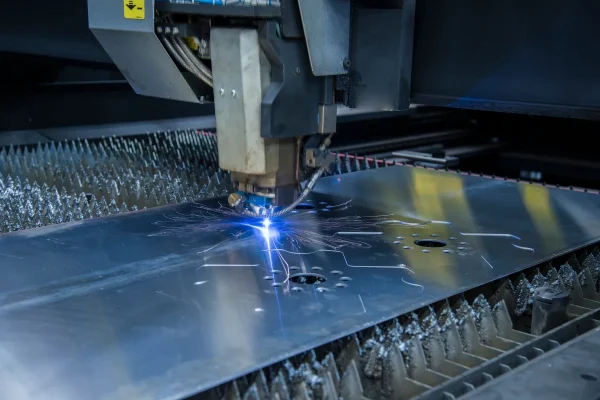

Laser Engraving

A high-powered laser system precisely etches or burns intricate designs onto metal surfaces, ideal for graphics, barcodes, and personalizations. Laser engraving offers a durable, permanent solution.

Showcase of Product Finishes

Explore our photo gallery to see the diverse and high-quality finishes we can provide for your custom products.

Technical Specifications

Explore the precise thickness, durability, maintenance, and compliance details of our finishes to choose the best option for your project needs.

Thickness Specifications

- Powder Coating: Typically applied at 60-80 microns to ensure optimal coverage and durability.

- Anodizing: Ranges from 5 microns for type II decorative finishes to 25 microns for type III hard anodizing used in harsh environments.

- Chrome Plating: Usually applied between 0.5 to 20 microns, depending on the required resistance to wear and corrosion.

Durability and Performance

- Painting: Tested for up to 500 hours of salt spray resistance, ensuring long-term performance in corrosive environments.

- Zinc Plating: Offers cathodic protection, with lifespan assessments showing effectiveness for up to 96 hours in salt spray tests without red rust.

Maintenance

- Nickel Plating: Requires regular cleaning with non-abrasive, pH-neutral cleaners to maintain its luster and prevent tarnishing.

- Polymeric Coatings: Simple maintenance involving routine washing with mild detergents; resistant to most chemical solvents, ensuring easy upkeep.

Standards and Compliance

- All finishes are applied in accordance with ISO 9001 quality standards, ensuring consistent quality management and process control.

- Environmental compliance with EPA regulations for VOC emissions in finishes, ensuring sustainability and safety.

FAQs

What are the benefits of powder coating on metal parts?

Powder coating offers excellent durability, impact resistance, and corrosion protection. It also provides a wide range of color options with a uniform finish that is more environmentally friendly compared to traditional liquid paints.

How does anodizing improve the properties of aluminum parts?

Anodizing enhances the natural oxide layer on aluminum, increasing its corrosion and wear resistance. It also allows for dyeing the metal in various colors, improving both cosmetic and mechanical properties.

Can plastic parts be plated, and what are the advantages?

Yes, plastics can be plated with metals such as chrome or nickel. This process enhances the aesthetic appeal of plastic parts, making them look metallic and more durable. It also improves wear resistance and electrical conductivity.

What is laser engraving and how is it applied to metal parts?

Laser engraving uses a high-powered laser beam to etch designs or text into the surface of a metal, creating precise and permanent markings. It is commonly used for serialization, branding, and decorative purposes.

What types of finishes are recommended for outdoor metal furniture?

For outdoor metal furniture, finishes that provide excellent UV resistance and weatherproofing are ideal. Powder coating and UV protective paints are highly recommended due to their durability and resistance to fading and weather conditions.

How does UV coating benefit plastic parts?

UV coating on plastic parts adds a protective layer that resists sun damage, prolonging the part’s lifespan and maintaining its appearance by preventing fading and brittleness.

What is the difference between pad printing and screen printing on plastics?

Pad printing can transfer 2D images onto 3D objects, making it ideal for printing on irregular surfaces like appliances and electronics. Screen printing, however, is better suited for larger, flatter surfaces and allows for thicker ink application, which can be more durable.

Request a Instant Quote!

Get a quick quote for your project with just a click! Request an instant quote now!

Contact Us