- بيت

- Capabilities

- Stainless Steel Investment Casting Service

High-Precision Stainless Steel Investment Casting Services

Welcome to HDC, your premier provider of high-precision stainless steel investment casting services. Whether you need complex components or intricate mechanical parts, our advanced technology and extensive expertise ensure top-notch solutions for your requirements. Our stainless steel investment casting products are renowned for their exceptional corrosion resistance, strength, and aesthetic appeal, making them ideal for various industries. Choose HDC as your trusted partner and elevate your business to new heights.

Advantages of Stainless Steel Investment Casting

Discover the key benefits of using stainless steel investment casting for your manufacturing needs.

Why Choose HDC Custom Stainless Steel Investment Casting Service

At HDC, we leverage advanced technology and a highly experienced team to provide top-notch stainless steel investment casting services. Our mature process workflows ensure that we can handle even the most complex designs with precision and accuracy. We prioritize customer satisfaction by offering customized solutions, flexible designs, and a wide range of sizes to meet your specific needs. Our efficient production methods guarantee timely delivery without compromising on quality, all at competitive prices.

In addition, we maintain stringent quality control standards throughout every stage of production, ensuring each component meets your exact specifications. Our extensive selection of stainless steel materials and post-processing options allows for superior corrosion resistance, strength, and durability in every product. Choose HDC for a reliable partner dedicated to delivering exceptional value and performance in every casting project.

Materials for Custom Stainless Steel Investment Casting Parts

Explore the diverse selection of high-quality materials offered by HDC for superior investment casting results.

304 Stainless Steel

Known for its excellent corrosion resistance, good weldability, and formability. It’s a versatile material suitable for a wide range of applications, including kitchen equipment, storage tanks, and automotive components.

316 Stainless Steel

Offers enhanced corrosion resistance, particularly against chlorides and other industrial solvents. Ideal for marine applications, chemical processing, and medical devices due to its superior strength and resistance to pitting and crevice corrosion.

410 Stainless Steel

Provides high strength and hardness, as well as good corrosion resistance. Often used in applications requiring wear resistance, such as valves, pumps, and cutlery.

420 Stainless Steel

Known for its high hardness and good corrosion resistance, particularly when polished. Commonly used in surgical instruments, cutlery, and tooling applications.

2205 Stainless Steel

Offers high strength and excellent corrosion resistance, particularly against chloride stress corrosion and cracking. Suitable for applications in the oil and gas, marine, and chemical processing industries.

17-4 PH Stainless Steel

Combines high strength, hardness, and corrosion resistance. Precipitation-hardened to achieve excellent mechanical properties, making it suitable for aerospace, chemical, and petrochemical industries.

Monel

Exceptional resistance to corrosion by acids and alkalis, and excellent mechanical properties at sub-zero temperatures. Commonly used in marine and chemical processing applications.

Stellite

Known for its outstanding wear resistance, hardness, and ability to maintain its properties at high temperatures. Typically used in cutting tools, valve seats, and bearing applications.

Hastelloy

Provides excellent resistance to a wide range of severe environments, including high temperatures and aggressive chemicals. Used extensively in chemical processing, pollution control, and aerospace applications.

Inconel

Renowned for its high strength and ability to withstand extreme temperatures and corrosive environments. Ideal for applications in gas turbines, nuclear reactors, and chemical processing.

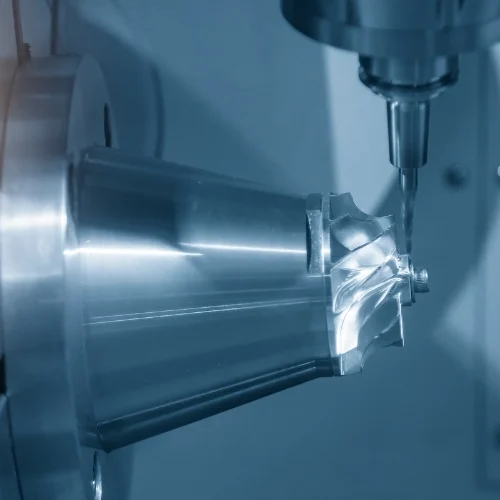

Introduction to Investment Casting Technology

Gain a comprehensive understanding of investment casting, its history, process, materials, precision, limitations, and future prospects.

Investment casting, also known as lost-wax casting, has a rich history dating back thousands of years to ancient civilizations. Modern advancements have refined this technique, making it a preferred method for producing complex and high-precision components. Its popularity surged during the 20th century with the advent of advanced materials and automation technologies.

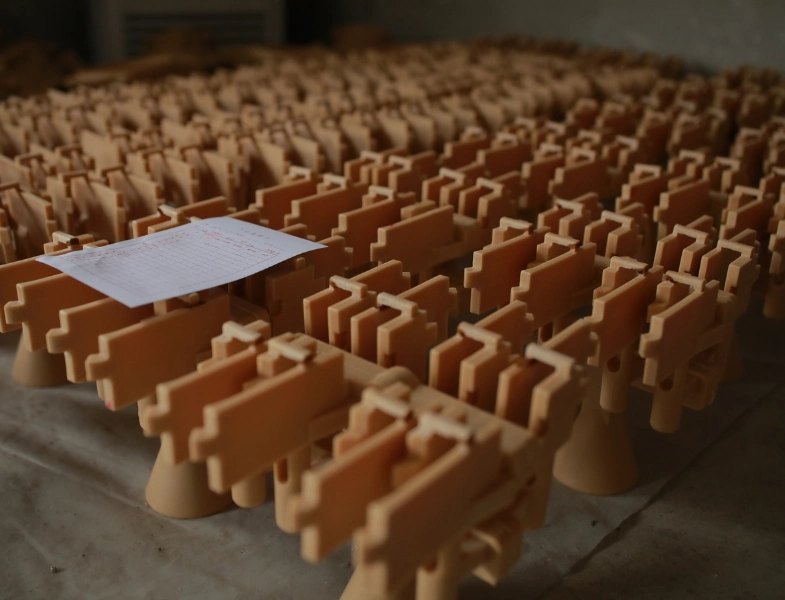

Process Workflow

- Pattern Creation: A wax pattern is made based on the desired component’s design.

- Assembly: Multiple wax patterns are assembled onto a wax tree.

- Shell Building: The wax tree is coated with ceramic material to form a hard shell.

- Wax Removal: The ceramic shell is heated to melt and remove the wax, leaving a hollow mold.

- Casting: Molten metal is poured into the mold.

- Cooling and Shell Removal: The metal cools and solidifies; the ceramic shell is broken away.

- Finishing: The cast parts are cut from the tree, cleaned, and finished to specifications.

Investment casting is versatile and can be used with a wide range of materials, including stainless steels (304, 316, 410, 17-4 PH, 420, 430), carbon steels, aluminum, copper, titanium, and nickel-based superalloys. This method is renowned for its high precision and excellent surface finish, capable of achieving tight tolerances and intricate details that are difficult to replicate with other manufacturing methods. This makes it ideal for aerospace, medical, automotive, and industrial applications.

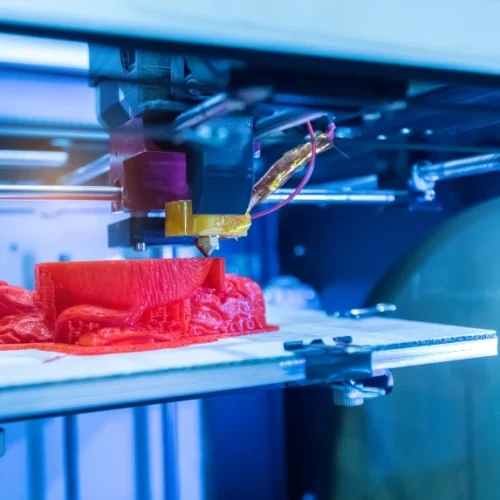

Despite its many advantages, investment casting has some limitations, including higher costs compared to other casting methods, size constraints, and longer lead times due to the detailed pattern and shell creation processes. However, the future of investment casting looks promising with ongoing advancements in materials science and automation. Innovations such as 3D printing of wax patterns and ceramic shells are expected to enhance precision and reduce lead times. Additionally, the development of new alloys and improved process controls will likely expand the range of applications and improve overall efficiency, making investment casting an even more attractive option for modern manufacturing.

Applications of Stainless Steel Investment Casting Across Industries

Discover how investment casting is utilized in diverse industries to produce high-precision and complex components.

Investment casting is ideal for producing lightweight, high-strength parts with intricate geometries such as turbine blades, engine components, and structural parts. These components are essential for the performance and efficiency of aerospace applications.

Aerospace Industry

The technique produces robust and wear-resistant parts like pumps, valves, and machinery components. These components are crucial for the efficiency and longevity of industrial machinery and equipment.

Industrial Equipment

Investment casting provides high-strength, precision parts for weapon components and military vehicle parts. These components meet the rigorous demands of defense applications, ensuring reliability and performance in critical situations.

Defense

This sector uses sheet metal in the production of large-scale energy systems, including wind turbines and solar panel frames. Sheet metal's robustness and weather resistance are essential for enduring the rigors of outdoor energy applications.

Energy Sector

Investment casting allows for the production of biocompatible, high-precision parts such as surgical instruments, implants, and dental components. These parts meet stringent medical standards, ensuring reliability and patient safety.

Medical EquipmentInvestment casting allows artists and jewelers to create intricate designs with excellent surface finishes for sculptures, decorative pieces, and fine jewelry, resulting in high-quality, detailed pieces.

Art and JewelryPrecision of Stainless Steel Investment Casting

Understand the exceptional accuracy and fine detail achievable with investment casting technology.

| Aspect | Detail |

|---|---|

| Dimensional Tolerances | ± 0.005 inches (± 0.127 mm) for the first inch; ± 0.002 inches (± 0.0508 mm) for each additional inch |

| Surface Finish | 63-250 microinches (1.6-6.3 micrometers) Ra |

| Wall Thickness | As thin as 0.040 inches (1.02 mm) |

| Weight Range | From a few grams up to several hundred kilograms |

| Complexity | High geometric complexity with fine details and intricate features |

| Material Variety | Wide range of alloys, including stainless steel, carbon steel, superalloys, and more |

Technical Specifications of HDC's Stainless Steel Investment Casting

| Specification | Details |

|---|---|

| Dimensional Tolerances | ± 0.005 inches (± 0.127 mm) for the first inch; ± 0.002 inches (± 0.0508 mm) for each additional inch |

| Surface Finish | 63-250 microinches (1.6-6.3 micrometers) Ra |

| Minimum Wall Thickness | 0.040 inches (1.02 mm) |

| Weight Range | From a few grams up to several hundred kilograms |

| Maximum Part Size | Up to 24 inches (600 mm) in length |

| Material Options | 304, 316, 410, 17-4 PH, 420, 430 stainless steels, carbon steels, and more |

| Heat Treatment | Available upon request, including annealing, normalizing, quenching, and tempering |

| Post-Processing Services | Machining, polishing, coating, and assembly |

| Quality Standards | ISO 9001:2015 certified; ASTM, DIN, and other international standards compliance |

| Lead Time | Typically 4-8 weeks, depending on complexity and volume |

Custom Stainless Steel Investment Casting FAQs at HDC

Get answers to common questions about customizing Swiss screw machined parts to ensure your project meets exact specifications.

Our typical lead time is 4-8 weeks, depending on the complexity and volume of the order. We strive to meet your deadlines without compromising on quality.

We offer a wide range of materials including 304, 316, 410, 17-4 PH, 420, and 430 stainless steels

We can achieve dimensional tolerances of ± 0.005 inches (± 0.127 mm) for the first inch, and ± 0.002 inches (± 0.0508 mm) for each additional inch.

Yes, we offer a variety of post-processing services including machining, polishing, coating, and assembly to meet your specific requirements.

Absolutely. Investment casting is ideal for creating parts with high geometric complexity, intricate details, and fine features.

Our processes are ISO 9001:2015 certified and we comply with ASTM, DIN, and other international standards to ensure the highest quality.

We can cast parts up to 24 inches (600 mm) in length and several hundred kilograms in weight.

Yes, we provide various heat treatment options upon request, including annealing, normalizing, quenching, and tempering to enhance the mechanical properties of the parts.

We implement stringent quality control measures at every stage of the production process, from pattern creation to final inspection, to ensure each component meets your exact specifications.

Yes, our experienced team can work with you from the initial design phase through to the final product, providing expert guidance and innovative solutions to meet your needs.

Get an Instant Quote!

Get a quick quote for your project with just a click! Request an instant quote now!

Contact With Us

for any inquiry

It enables the manufacturing of durable and precise parts like engine parts, transmission components, and brake systems. These parts can withstand high temperatures and stresses, thereby improving vehicle performance and safety.

Automotive Industry