Out of the many different grades of stainless steel, A286 stainless steel is one of the most commonly used alloys in the manufacturing industry. In case you don’t know about it, or in case you haven’t heard of what it is, we got just what you need!

In this blog, we’ll go about finding every information you need to know about A286 stainless steel. We’ll discover and figure out what it is, what it’s used for, why it’s the top choice for most industries, and everything else!

What is the A286 Alloy in Stainless Steel?

If you’ve been long in the industry, you know that there are four families of stainless steel. The A286 happen to be an alloy part of the austenitic family because of its nickel-chromium content.

Check this video out to understand A286 stainless steel alloys!

It’s the one of many important and common alloys of stainless steel because of its high-level corrosion, temperature, and wear resistance.

NOTE: Many businesses and establishments consider and label them as “Incoloy” or “superalloy” because of its high strength and temperature resistance.

What Material is A286 Made Of?

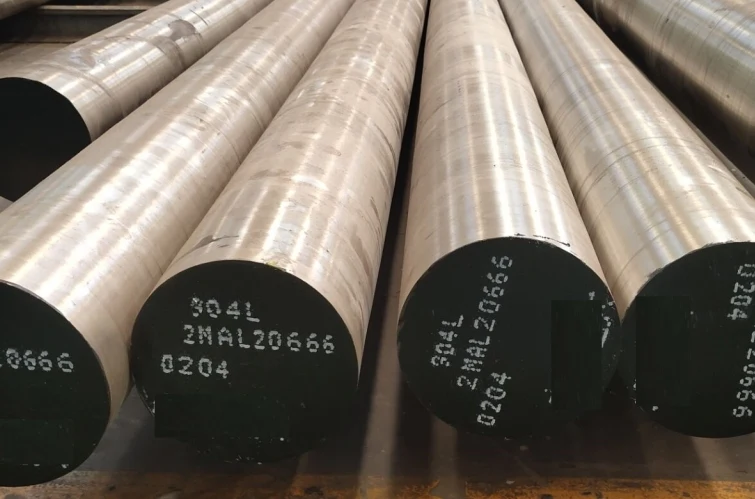

Source: Alloy Wire

Understanding the composition and what A286 is made of isn’t rocket science. We just need to know what the primary material it’s based off of. A286 is an iron-based superalloy that’s known for its high strength and resistance.

Here’s a quick glance at the composition of A286:

| Element | Content (%) |

| Iron, Fe | 54 |

| Nickel, Ni | 25.5 |

| Chromium, Cr | 14.8 |

| Titanium, Ti | 2.13 |

| Molybdenum, Mo | 1.3 |

| Manganese, Mn | 1 |

| Silicon, Si | 0.5 |

| Vanadium, V | 0.3 |

| Aluminum, Al | 0.18 |

| Carbon, C | 0.04 |

| Phosphorous, P | 0.02 |

| Sulfur, S | 0.015 |

| Boron, B | 0.006 |

A big thank you to AZO materials for providing this comprehensive list of elements that make up A286!

Understanding A286 Stainless Steel Properties and Characteristics

Source: LTD Pipeline System

We know it’s iron-based, that it has high strength and high resistance, and they can perform in extreme temperatures. But how deep is your knowledge about their characteristics and other properties?

Let’s take a look at each of their properties carefully, so you know what you’re up against!

A286 Material Properties

This Incoloy offers a unique balance of strength, oxidation resistance, and toughness. It contains iron, nickel, chromium, and molybdenum. These, overall, enhances durability and longevity even in the harshest environments.

The alloy retains its mechanical properties up to 1300°F (700°C), making it ideal for high-heat applications.

A286 Stainless Steel Machinability

A286 is a strong and heat-resistant alloy, but its machinability is moderate. To prevent work hardening, carbide tooling is required, as are slow cutting speeds.

Proper lubrication improves tool life and surface finish, reducing wear during machining operations and making sure that there’ll be no congestion or clumps while the machine is operating and working.

Check out Michlin Metals Inc’s explanation of A286 stainless steel properties!

Temperature Resistance

A286’s temperature resistance is known to sit at 704 °C or about 1300 °F. This is true for both lower and higher stress applications, making them ideal for complex uses and applications.

A286 Tensile Strength

This alloy’s tensile strength is also remarkable. Sitting at approximately 130-160 ksi (896-1103 MPa) in solution-treated conditions, you’re sure that failure will only happen during extremities.

This high tensile strength ensures that the A286 steel is able to withstand extreme loads without failure, making it suitable for critical aerospace and industrial parts.

A286 Stainless Steel Yield Strength

Yield strength, in case you didn’t know, is an indicator of the stress level at which the material begins to deform permanently, ensuring reliability in demanding applications.

For our friend, the yield strength typically ranges between 75-85 ksi (517-586 MPa). This, however, is depending on the heat treatment done to it. It’s a moderate-level type of yield strength allowing extra coverage.

A286 Density

And last but most certainly not least is density. A286 stainless steel boasts a density of approximately 7.94 g/cm³ (0.287 lb/in³), like what other iron-based alloys usually sit at.

In case you were wondering, the density wholly contributes to its excellent strength-to-weight ratio, making it an ideal choice for weight-sensitive applications in aerospace and high-performance industries.

And those are the properties and characteristics of the famous A286 stainless steel. Most of us know these general information by heart, but it’s good to have knowledge of them in detail, too!

What is A286 Stainless Steel Equivalent To?

Source: Wieland Diversified

This Incoloy is equivalent to certain stainless steel grades, namely Inconel Alloy A286, UNS S66286, and DIN 1.4980.

Why is HDC Manufacturing Your Best Partner For A286 Stainless Steel?

A286 may be common, but an expert like us at HDC Manufacturing who knows workarounds for superalloys is not. For more than a decade now, our services and products all have been linked to the best sources globally.

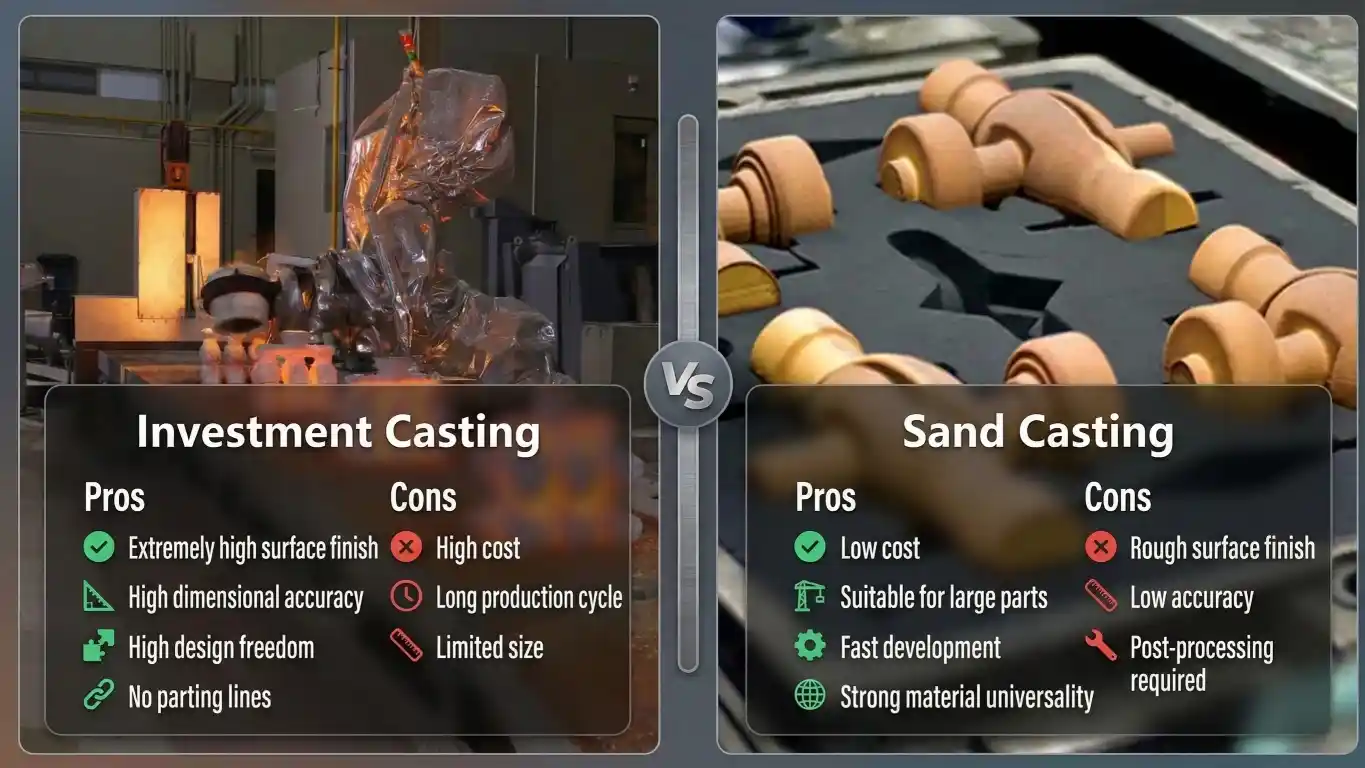

Our mastery in the stainless steel, metal, and plastic industries allow us to be more flexible and versatile. We’re adept and skilled in many industries, including investment casting. HDC Manufacutring is one of the few manufacturers that offer high-level investment casting, so contact us if you need help with it.

Besides A286 stainless steel, though, our other common points of expertise include, but are not limited to carbon steels, aluminum alloys, copper alloys, plastics, and many more! That being said, you know that you can count on us whatever industry you might be in!

Don’t think twice or hesitate to contact us here at HDC Manufacturing if you need help or have any questions! Get a free quote and never worry who to partner with again!