Comprehensive Guide to Big Hinges: Types, Applications, and Maintenance

Big hinges play a crucial role in supporting heavy doors, gates, and machinery. If you've ever wondered about the mechanics behind these heavy-duty hardware components, you're in the right place. In this comprehensive guide, we'll delve into the world of big hinges, exploring their types, applications, and how to choose, install, and maintain them. By the end of this article, you'll have a solid understanding of why big hinges are essential and how to make the most of them in various scenarios.

What Are Big Hinges

“Big hinges” typically refer to large or oversized hinges. Hinges are mechanical devices that allow two objects to pivot or rotate relative to each other, like a door swinging open and closed. When someone mentions “big hinges,” they are likely referring to hinges that are designed to support heavy doors or objects, which require larger and more robust hinges for stability and durability.

Benefits of Big Hinges

Big hinges offer notable advantages, including stability and security, crucial for applications like gates and exterior doors. Moreover, their durability ensures longevity and reliability, reducing the need for frequent replacements.

Applications of Big Hinges

- Heavy Exterior Doors: Big hinges are often used on heavy exterior doors, ensuring they can swing open and close smoothly and securely.

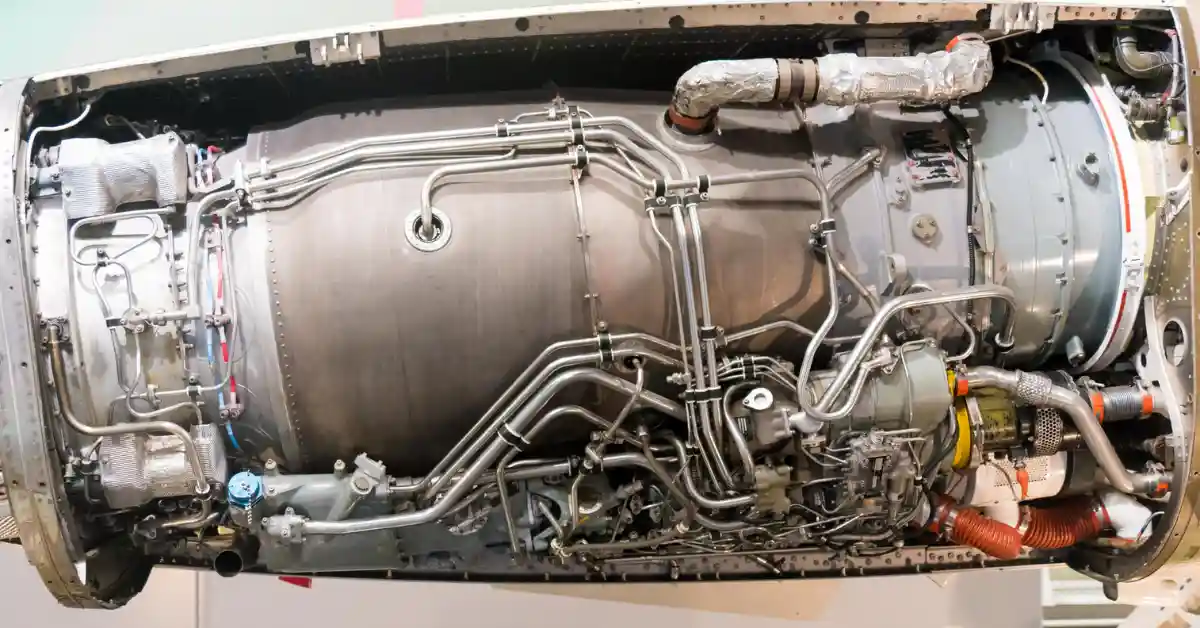

- Industrial Machinery: Machinery in industries like manufacturing, construction, and agriculture often rely on big hinges for moving parts and access panels.

- Large Gates: Gates that protect properties, farms, or industrial facilities frequently use big hinges to provide stability and security.

Types of Big Hinges

- Strap Hinges: Known for their long, flat design, they are often seen on gates, barn doors, and decorative exterior doors, offering both support and aesthetic appeal.

- Piano Hinges: Ideal for applications requiring continuous and smooth movement, they run along the entire length of a door or panel, common in piano lids and foldable tables.

- Butt Hinges: Versatile and found in a variety of doors, cabinets, and gates, they come in various sizes to accommodate different load capacities.

Materials and Finishes for Big Hinges

Materials for Big Hinges:

- Steel: Known for strength and durability, ideal for heavy-duty use.

- Brass: Chosen for its attractive appearance and corrosion resistance.

- Bronze: Combines strength and aesthetics, developing a natural patina.

- Aluminum: Lightweight and corrosion-resistant, suitable for weight-conscious applications.

Finishes for Big Hinges:

- Polished Finish: Provides a shiny, elegant appearance.

- Satin Finish: Offers a smooth, matte look.

- Antique Finish: Gives a weathered appearance, popular in rustic settings.

- Powder-Coated Finish: Provides durability and corrosion resistance.

- Black Finish: Offers a classic, bold look.

- Oil-Rubbed Finish: Creates a dark, aged appearance.

The choice of materials and finishes depends on the specific application, aesthetics, and environmental considerations, with durability and corrosion resistance being key factors.

Load Capacity of Big Hinges

- Strap Hinges: These can support loads from 100 pounds to several thousand pounds, depending on size and material.

- Piano Hinges: Typically handle loads ranging from 100 to 300 pounds, with heavier options for industrial use.

- Butt Hinges: Load capacity varies widely, from 20 pounds for smaller hinges in cabinets to several thousand pounds for larger, heavy-duty versions in doors and gates.

Choosing the Right Big Hinge

- Materials and Durability

- Weight Capacity

- Installation Considerations

Installation and Maintenance

- Mark hinge locations accurately.

- Use appropriate tools and hardware.

- Ensure precise alignment.

- Securely attach the hinge to the door or gate.

- Regularly lubricate the hinge pivot points to prevent squeaking.

- Periodically check for misalignment and make necessary adjustments.

How to Custom Big Hinges

To order custom big hinges from a manufacturer, begin by defining your hinge requirements, researching reputable manufacturers, and initiating contact with them. Request a comprehensive quote, select appropriate materials, collaborate on the design and engineering phase, and ensure rigorous testing and quality assurance. Keep a close eye on production and delivery schedules, inspect the hinges upon receipt, complete payments, and adhere to installation guidelines. Follow maintenance recommendations for long-term performance and reach out to the manufacturer for support as needed. Effective communication and collaboration with the manufacturer are essential to ensure that the custom hinges meet your specific project requirements.

Conclusion

In this article, we’ve explored the world of big hinges, understanding their types, applications, and the importance of choosing the right hinge for your project. We’ve also covered installation and maintenance tips, benefits, and how to address common issues. With this knowledge, you can confidently use big hinges in various heavy-duty applications, ensuring longevity and reliability.