In terms of metalworking, selection of the proper manufacturing process is very critical. Forging and casting are among the most popular but each carries its own strengths and weaknesses as well as usage. When choosing the type of process to use in your next project, you need to know the differences between the different processes, as this may save time, money and effort.

Here you will find a guide on all that you need to know about forging vs casting in 2026. You will have all the information on what process best suits your project by the end of this article.

1. What is Forging?

Define Forging

Forging is a manufacturing process whereby metal is formed under compressive forces. In comparison with casting, which heats metal and pours it into molds, forging is the process of deforming solid metal, usually with hammers or rollers. It is a process that has been in place since time immemorial in order to produce strong and reliable metal parts.

2. What is Casting?

Define Casting

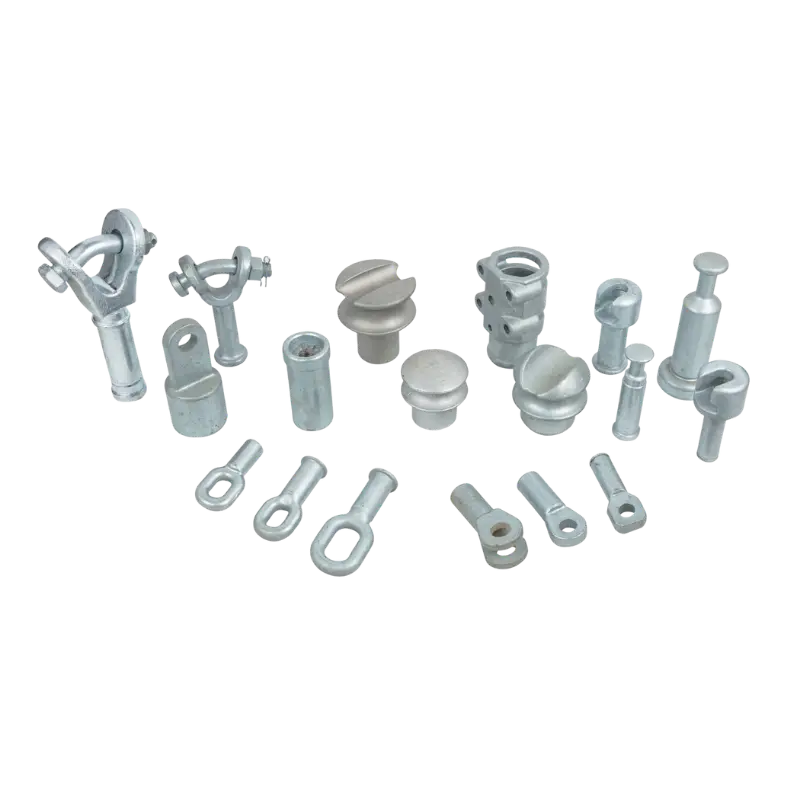

Casting is the procedure in which molten metal is emptied into a mold and left to harden. When the metal is cooled, it becomes in the shape of the mold. The process is also perfect in making complicated components that would have been hard or impossible to forge.

3. Forging vs Casting: Key Differences at a Glance

Before diving into detailed performance, cost, and application analysis, it helps to understand the fundamental differences between forging and casting at a high level. The comparison below provides a quick reference to help you grasp how the two processes differ—without going into technical depth, which will be covered in later sections.

| Feature | Forging | Casting |

|---|---|---|

| Basic Process | Metal is shaped under compressive force in solid state | Molten metal is poured into a mold and solidifies |

| Internal Structure | Continuous, aligned grain flow along part geometry | Random grain structure, may contain porosity or shrinkage |

| Mechanical Reliability | High, suitable for load-bearing and safety-critical parts | Moderate, suitable for non-critical or medium-load components |

| Material Waste | Low, minimal scrap | Moderate, some material lost during molding and finishing |

| Shape Freedom | Limited to simpler geometries | High, allows complex, hollow, or intricate designs |

| Surface Finish / Finishing | Usually smooth; minimal post-processing | Often rough; may require grinding, polishing, or heat treatment |

| Tooling / Production Economics | High initial die cost; cost-effective for critical parts | Low initial mold cost; cost-effective for high-volume production |

| Production Volume Suitability | Better for low to medium volumes with high quality | Efficient for large-volume production |

| Typical Use Cases | Crankshafts, gears, landing gear, structural components | Engine blocks, housings, decorative items, complex industrial parts |

| High-Stress vs Non-Critical Parts | Best for high-stress, fatigue-prone applications | Suitable for non-critical or ornamental applications |

4. Forging vs Casting Performance Comparison

Precision and Shape Complexity

Casting works better in cases of complex design, geometrics, and hollow parts, including engine blocks and ornaments. It also permits designers to make shapes that are hard or unable to be forged.

Forging is however restricted to simpler forms but it has better structural integrity. Although it is impossible to make really complicated designs, forged components are stronger and less likely to be stressed out.

Tensile and Impact Strength

Forged components are strong in tensile strength and impact resistance since forging makes the internal grain structure of the metal oriented. This renders them able to deal with extreme loads and peak impacts, which are important in automotive usage, aerospace usage and heavy machinery utilization.

Although cast parts are applicable in most applications, they might not withstand any stress because of the casting defects, such as porosity or unequal cooling.

Fatigue Resistance

Components that are exposed to stress cycles are important for fatigue resistance. In this respect, forged parts are superior to cast parts and are suitable in rotating shafts, gears and structures subject to loading.

Cast components can also develop micro-cracks or stress points at any point in time, which can shorten the operational life of that component in heavy stressing use.

Dimensional Accuracy

Casting permits accurate and complicated geometrics, such as hollow sections, detailed geometrics and part shapes. It is best when you require precise designs and beauty, particularly in automotive, industrial or ornamental parts.

Forging does not compromise the structural integrity of simpler shapes, whereas it is not the case with the complexity of high-stress applications. Forged components can be machined to give the right dimensions but usually the strength is more advantageous than the extra work.

5. Cost Comparison: Forging vs Casting

Cost Breakdown

- Tooling: High-cost dies are necessary in forging and the cost of casting molds is normally low.

- Labor: Forging labor is a skilled labor that is more expensive and casting is more automated.

- Material: Forging creates a relatively small amount of waste, whereas casting creates a small amount of scrap.

- Speed of Production: Casting can be done more rapidly in large quantities, however forging might be slower but give stronger components.

When Casting is Cheaper

- Big, bulky components in which high stress is not critical.

- Mass production to lower the labor costs.

- Ornamental or nonstructural elements.

When Forging Pays Off

- Important parts such as crankshafts, landing gear and turbine shafts.

- Components that must be the most fatigue resistant and durable.

- Applications with high stress levels and failure are not an option.

6. Types of Metals Best Suited for Forging and Casting

Metals Ideal for Forging

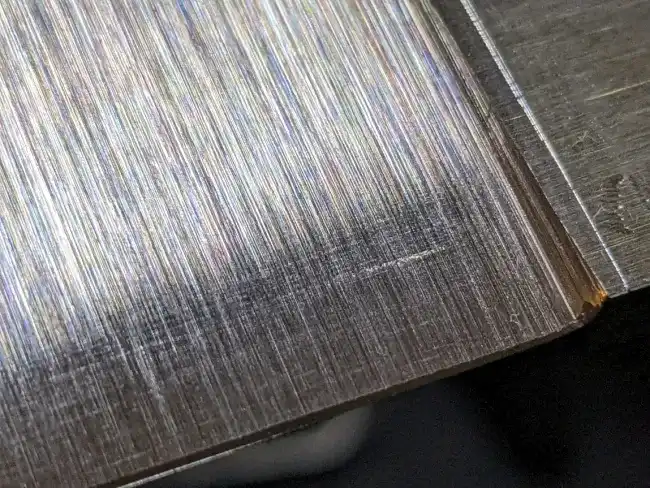

- Steel: Steel is another one of the most common metals to be forged. It is strong in tensile and has high fatigue as well as durability, which makes it suitable in automotive components, aerospace components and heavy machinery. The steel is forged to enhance its grain structure which makes it stronger and more reliable.

- Aluminum Alloys: Aluminum alloys are light but strong and are thus ideal in the aerospace and transportation as well as machinery industries. Aircraft components, bicycle frames and and high-performance automotive parts are some of the aviation components that are forged aluminum parts.

- Titanium: Titanium has been regarded as having an amazing strength-to-weight ratio and corrosion resistance. Counterfeit titanium is extensively used in the aerospace industry, medical implants and high-performance engineering in which the weight and longevity are important.

Metals Ideal for Casting

- Iron: Iron is cheap to cast and simple to cast and this makes it the choice for engine blocks, huge engine parts, and construction items. Large and complex forms can be produced through casting, which would be hard to forge.

- Aluminum: Aluminum casting is a favorite for light parts that are detailed. It is extensively utilized in automobile and machinery market, such as in housings, brackets and engine parts.

- Bronze: Bronze casting is favored in ornamentation, bearings and corrosion-free parts. It is widely used in art, architecture and industry because of its capability to create complex designs.

Metal Selection Table

| Metal | Forging | Casting | Typical Use |

| Steel | Yes | Optional | Autombiles, aviation and heavy equipment. |

| Aluminum | Yes | Yes | Aerospace, machinery, transportation. |

| Titanium | Yes | Limited | Spark gears, medical implants, aerospace and high performance. |

| Iron | Limited | Yes | Engines, pumps and construction equipment. |

| Bronze | No | Yes | Ornamental objects, insignia and arts. |

7. Forging vs Casting Applications Across Industries

Automotive Industry Applications

- Forging: Forged crankshafts, gears, control arm and axles have a very high degree of durability and they are able to endure extreme stress and torque in automobiles. Forged components guarantee safety and reliability of main parts in the automotive industry.

- Casting: Engine blocks, exhaust manifold, transmission housings and other complicated components are usually cast. Casting enables the manufacturers to make huge and complex shapes with less cost when the production is in large volumes.

Aerospace Industry Applications

- Forging: Partial components of the landing gear, such as turbine shafts, structural support and landing gear are forged to resist fatigue and provide strength. These sections should be able to endure the severe stress and tough environment.

- Casting: Structural brackets and housings and selected engine components are cast so that they can be designed with complex geometrics without functionality being compromised.

Industrial Machinery and Construction

- Forging: The parts of machinery, heavy hears and structures are forged so that they become durable and have a long life.

- Casting: Castings are done on pumps, values and large machine parts. This will enable manufacturers to make complicated shapes and oversized components with ease.

Artistic and Decorative Uses

- Casting: The most popular in sculptures, decorations and complex elements of buildings. Casting makes it possible to use very detailed ornamental designs that could not be realized in forging.

8. Advanced Forging and Casting Techniques in 2026

Modern Forging Innovations

- Precision Forging with an Automated Press: One that guarantees better parts that are consistent and of excellent quality and have very few errors.

- Induction Heating for Uniform Metal Flow: Enhances the material properties and minimizes defects that are due to unequal heating.

- High-Strength Alloys for Lightweight Components: Lightweight components allow more robust but less heavy components to be produced in applications such as aerospace and automobiles.

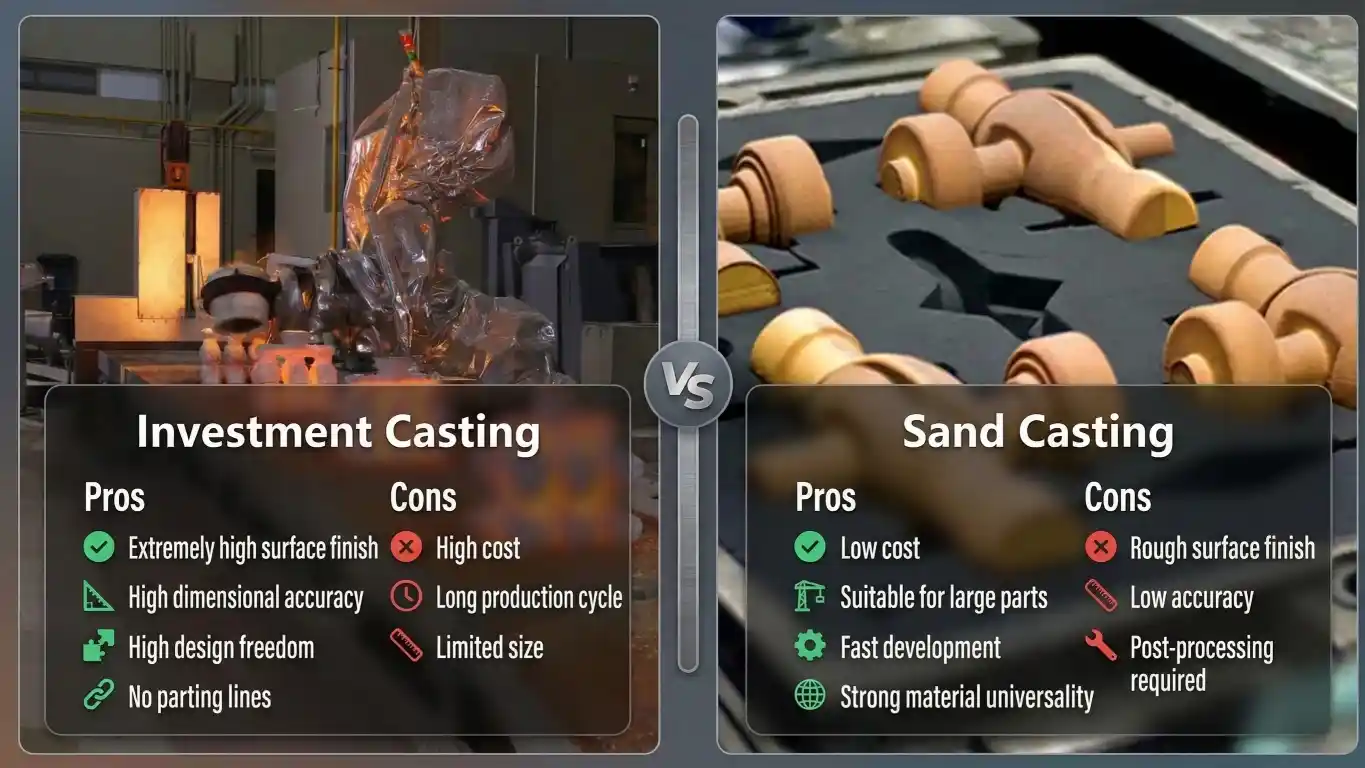

Modern Casting Innovations

- Vacuum Casting to Remove Porosity: Produces flawless products that are stronger and enhanced in surface finish.

- Faster, Accurate Production of 3D Printed Molds: Faster process, quicker prototyping and fewer errors in molds.

- Lost-Wax Method of Complex Designs: Allows very finely detailed components to be made for use in industry and ornamentation.

How Tech Improves Quality

These new methods do not need match waste, enhance the dimensional accuracy and are cost-effective and these methods do not compromise the parts’ durability and performance. Manufacturers are now able to make more dependable components with minimal human effort and the number of defects.

9. How to Choose Between Forging and Casting

Key Questions to Ask

Before deciding on which method to use between forging and casting, the following queries are to be asked:

- What is the load that the part will carry? When a component will be subjected to high stress, repeated fatigue or high impact, the better option is forging, as it has a higher level of strength.

- Do you need a complex shape? Casting may be more appropriate in complex designs, hollow components or geometries of detail. Faking is effective with a shape that is simple.

- What does the production volume entail? Casting can be adapted to high-volume production because molds enable the production to be quicker. Forging may prove to be cheaper at lower quantities with better quality requirements.

- What is your Budget? Look beyond the initial prices to long-term durability and maintenance. The forging may be more expensive initially but will pay off in strength; the casting may not require money on a large scale or for ornamental parts.

Decision-Making Flowchart

The following is an easy visualization of your decision:

- High Stress + Simple Shape → Forging: Best with crankshafts, gears and load-carrying parts.

- Complex Shape + Low-Medium Stress → Casting is ideal for engine blocks, housings and artistic designs.

- High Volume → Casting can be Economical: Less work and material wastage when one is casting in large amounts.

- Critical Safety Component → Forging: The maximum reliability of aerospace, automotive or heavy machinery is guaranteed.

Tips for Cost-Effective Choices

- Focus on high-stress, long-life parts. The cost of parts is more expensive due to initial expenses but the durability of the part is a cost-saving on maintenance and replacement.

- Select casting of the complicated, high-volume components. You are able to make complex designs more cheaply and in less time.

- Use hybrid solutions in some cases; forged and cast elements of a design may offer the optimal mix of strength and cost as well as complexity.

10. Common Mistakes in Forging and Casting

Forging Mistakes

- Heating the Metal: It is possible to make the material weaker and create cracks. There must be maintenance of correct temperature.

- Ignoring Material Properties: It may result in premature failure in case the incorrect alloy is used. Determine the match between the load and application and the metal.

- Overstressing Dies: Large loads may cause tool breakages and may also influence part quality. Check pressure and wear of dies.

Casting Mistakes

- Poor Mold Design: Wrong molds may result in flaws or misfits. Simulate the flow of the mold before manufacturing.

- Improper Cooling Leading to Shrinkage: If the cooling is not done evenly, weak points or dimensional mistakes may arise. Do not use excessive cooling rates.

- Neglecting Finishing Requirements: Surfaces or flaws can be rough, thus undermining performance. Preplanning after processing.

How to Avoid Defects

- Choose material well and also control the temperature used in forging or casting.

- Test components with modern testing like X-ray inspection, ultrasonic testing or dye-penetrant tests.

- Make end finish plans and tolerance plans to achieve the design requirements.

11. Expert Tips for Maximizing Results in 2026

Material Selection Tips

- Always use the matching metal with the necessary strength, weight and corrosiveness.

- When it comes to critical applications, it is worthwhile to invest in high-grade alloys to avoid failure.

Quality Control Techniques

- Find internal defects using non-destructive testing (NDT).

- X-ray inspection and ultrasonic inspection are able to detect undetected defects during the manufacture of parts.

- Introduce periodic inspection schedules to ensure that the quality of production is observed.

Sustainability in Metalworking

- Recycle scrap material to save on costs and reduce the impact on the environment.

- Reduce wastage of materials by accurate planning of forging and casting.

- Select energy-efficient machinery that will reduce the cost of production and enhance sustainability.

12. Conclusion

The decision to go in for forging vs casting will always be determined by the needs of your project, budget and production needs. Forging is more reliable and stronger, whereas casting provides cost-efficient solutions to intricate shape and volume production. Knowing their application use, you will be able to make a wise decision.

FAQs

What is Stronger: Forging or Casting?

Forged components tend to be stronger in that there is better internal structure and reduced internal defects.

Which process is Cheaper for Small parts?

Small complex parts that are not stress sensitive are typically cast cheaper.

Can casting match forging’s durability?

However, in certain applications, casting can be done using advanced techniques such as the use of vacuum casting, which can provide reliable parts, although in high-stress situations, forging remains the dominant technique.

Which industries rely on forging or casting most?

Forging is essential in aerospace industries as well as the automotive and heavy machinery industries.

Forged components tend to be stronger in that there is better internal structure and reduced internal defects.

Small complex parts that are not stress sensitive are typically cast cheaper.

However, in certain applications, casting can be done using advanced techniques such as the use of vacuum casting, which can provide reliable parts, although in high-stress situations, forging remains the dominant technique.

Forging is essential in aerospace industries as well as the automotive and heavy machinery industries.