Mastering CNC Swiss Screw Machining with Precision and Efficiency

CNC Swiss Screw Machining is a state-of-the-art manufacturing technique for producing small, intricate components with exceptional precision and efficiency. This blog explores the key benefits, such as high accuracy, versatility in materials, and reduced setup time. It highlights applications in the medical, aerospace, and automotive industries, addresses material selection, and discusses challenges like tooling complexity and tight tolerances. Additionally, the blog delves into future trends, including Industry 4.0 integration and advanced automation, offering insights for optimizing processes and managing costs.

What is CNC Swiss Screw Machining

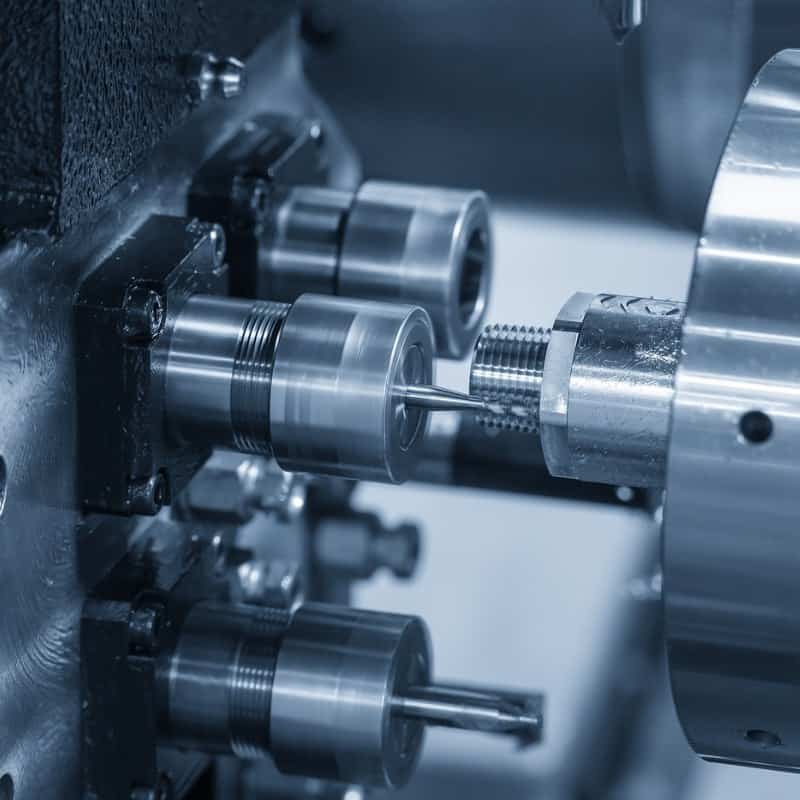

CNC Swiss Screw Machining is an advanced and precise manufacturing technique used in the production of small, intricate components with tight tolerances. It is a form of computer numerical control (CNC) machining that originated as an enhancement of traditional screw machining. This method is characterized by its ability to perform multiple machining operations in a single setup, leading to increased efficiency and accuracy.

In CNC Swiss Screw Machining, a rotating bar stock is fed through a guide bushing, which provides support and stability during the machining process. The machining tools, controlled by computer programs, move in various directions to shape the material and create the desired components with exceptional precision. This process is particularly well-suited for small parts that require high levels of accuracy and intricate details.

Advantages of CNC Swiss Screw Machining

High Precision: One of the primary advantages of CNC Swiss Screw Machining is its exceptional precision. Unlike conventional machining methods, it achieves tight tolerances, making it ideal for intricate and complex components.

Versatility in Materials: CNC Swiss Screw Machines exhibit remarkable versatility in handling various materials, from traditional metals to advanced plastics and exotic alloys. This flexibility broadens the scope of applications across industries.

Reduced Setup Time: Efficiency is paramount in manufacturing, and CNC Swiss Screw Machining excels in reducing setup time. The streamlined process ensures quicker production cycles, contributing to cost-effectiveness.

Applications of CNC Swiss Screw Machining

Medical Device Manufacturing

In the medical field, precision is non-negotiable. CNC Swiss Screw Machining plays a pivotal role in crafting intricate components for medical devices, ensuring the highest quality standards.

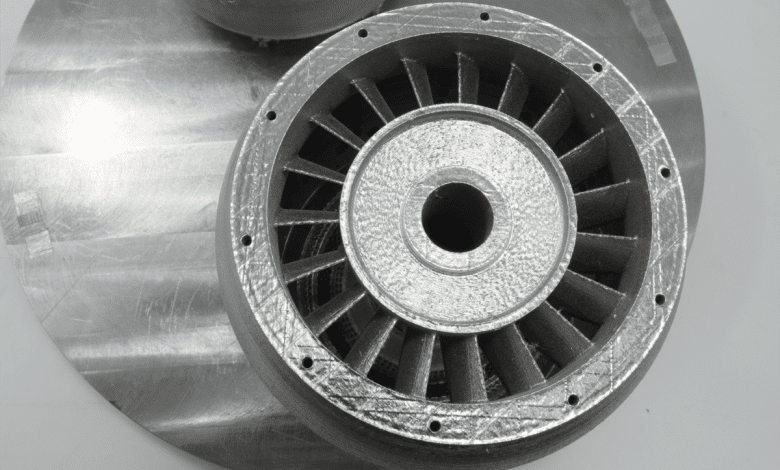

Aerospace Components

Aerospace demands components with uncompromising precision and durability. CNC Swiss Screw Machining caters to these requirements, producing critical parts for the aerospace industry.

Automotive Parts

From engine components to intricate transmission parts, CNC Swiss Screw Machining finds its application in crafting high-precision automotive parts, contributing to the efficiency and performance of vehicles.

Material Selection for CNC Swiss Screw Machining

Selecting the right materials for CNC Swiss screw machining is crucial to ensure optimal performance, machining efficiency, and the overall success of the manufacturing process. Here are some considerations when selecting materials for this machining process:

- Machinability: Opt for materials like stainless steels, aluminum alloys, and specific brass and copper alloys known for good machinability.

- Material Strength: Consider the mechanical properties needed; stainless steels or alloy steels may be suitable for high-strength applications.

- Corrosion Resistance: Choose materials based on the final product’s exposure to environmental conditions; stainless steels and corrosion-resistant alloys are common for parts requiring protection.

- Thermal Conductivity: Evaluate thermal conductivity based on the application; aluminum alloys are suitable for components requiring efficient heat dissipation.

- Cost Considerations: Balance performance requirements with cost-effectiveness; exotic alloys may offer advantages but can be expensive.

- Size and Complexity of Parts:Select materials that suit the intricacy and size of the parts; easily machinable and formable materials, like certain brass alloys, may be preferred.

- Surface Finish Requirements: Consider the surface finish needed; materials like stainless steel can provide a smooth finish, but it also depends on machining processes and tools.

Challenges in CNC Swiss Screw Machining

Tooling Complexity

Despite its advantages, CNC Swiss Screw Machining presents challenges, such as the complexity of tooling. Machinists must navigate intricate setups to achieve the desired precision.

Small Part Size

Working with small parts demands meticulous attention to detail. CNC Swiss Screw Machining excels in this area but requires specialized expertise to handle miniature components effectively.

Tolerances and Surface Finish

Meeting tight tolerances and achieving the desired surface finish can be challenging, necessitating careful calibration and monitoring throughout the machining process.

Future Trends in CNC Swiss Screw Machining

Integration with Industry 4.0:

The future of CNC Swiss Screw Machining involves seamless integration with Industry 4.0 technologies, fostering connectivity and data-driven decision-making for enhanced productivity.

Advanced Automation:

Automation will play a pivotal role in the evolution of CNC Swiss Screw Machining, reducing manual intervention and further improving efficiency and precision.

Tips for Optimizing CNC Swiss Screw Machining Processes

Tool Selection: Choosing the right tools is crucial for optimizing CNC Swiss Screw Machining processes. Machinists should carefully select tools based on material, part complexity, and desired tolerances.

Machine Setup: Efficient machine setup is key to maximizing productivity. Machinists must pay attention to details such as tool alignment, workpiece positioning, and coolant management.

Quality Control Measures: Implementing rigorous quality control measures throughout the machining process ensures that the final components meet the required specifications and standards.

Cost Considerations in CNC Swiss Screw Machining

Initial Investment

While CNC Swiss Screw Machines offer unparalleled precision, the initial investment can be significant. However, the long-term benefits in terms of efficiency and quality often outweigh the upfront costs.

Operating Costs

Regular maintenance, tool replacements, and energy consumption contribute to the operating costs of CNC Swiss Screw Machining. Proper management is essential to optimize cost-effectiveness.

Comparison with Other Machining Processes

CNC Milling and Turning:

Compared to CNC milling and turning, CNC Swiss Screw Machining excels in handling small, intricate parts with higher precision, making it the preferred choice for certain applications.

Traditional Screw Machining:

While traditional screw machining has its merits, CNC Swiss Screw Machining offers advanced capabilities, improved precision, and greater versatility in material handling.

Custom CNC Swiss Screw Machining Parts

When seeking custom CNC Swiss screw machined parts from manufacturers, it’s important to follow a structured process:

- Clearly define project specifications.

- Research reputable manufacturers with expertise.

- Collaborate on material selection and design.

- Request detailed quotations and clarify terms.

- Consider prototyping for validation.

- Plan production schedule and quality assurance.

- Maintain open communication throughout.

- Discuss secondary operations and finishing.

- Participate in testing and inspection procedures.

- Coordinate packaging and delivery according to requirements.

By following these steps and fostering a collaborative relationship with the manufacturer, you can ensure a successful and efficient production of custom CNC Swiss screw machined parts.

Conclusion

In conclusion, CNC Swiss Screw Machining stands as a cornerstone in modern manufacturing, offering unparalleled precision, versatility, and efficiency. As industries evolve, embracing the latest technologies and trends in CNC Swiss Screw Machining becomes imperative for staying competitive in today’s market.