Most of you with knowledge in the metal market know what 300 series stainless steel is. But for some of you just starting out in the industry, it could be vague ideas that you’ve heard or you think about, but don’t really know.

Over the past few years, the abundance of 300 series stainless steel took us by surprise. So, in this blog, we’ll go over 300 series stainless steel in a jiffy. We’ll jump through and fill crevices and cracks, finding out important information about it that you should know!

Understanding Stainless Steel and its Different Families

Source: Ulbrich

Because of changes, innovation, and the continuous growth of factors, stainless steel is categorized into different families. These families are categorized based on alloying elements and composition, impacting direct properties like conductivity, corrosion resistance, temperature and wear resistance, and more.

The different families of stainless steel are the following:

Austenitic

The most common family is austenitic. They’re known for their excellent corrosion resistance and flexibility. It contains high levels of chromium and nickel, making it ideal for food processing, medical tools, and marine applications.

Ferritic

Ferritic stainless steel is magnetic and resists corrosion well, but it is not very strong. Because it is inexpensive and simple to fabricate, it is frequently utilized in appliances, automobile parts, and decorative applications.

Duplex

Duplex stainless steel offers a balance of strength and corrosion resistance, combining austenitic and ferritic structures. It is widely used in chemical processing, offshore structures, and pipelines.

Martensitic

Martensitic stainless steel is strong, hard, and wear-resistant but has lower corrosion resistance. They’re known as perfect materials for knives, turbine blades, and industrial tools that require durability.

Precipitation-Hardening Stainless Steel

And last but not least, precipitation-hardening stainless steel. This type is heat-treated to achieve exceptional strength while maintaining good corrosion resistance. They’re used commonly in aerospace, military, and high-performance engineering applications.

Here’s a brief overview of the different families and classifications of stainless steel!

What is the 300 Series Stainless Steel?

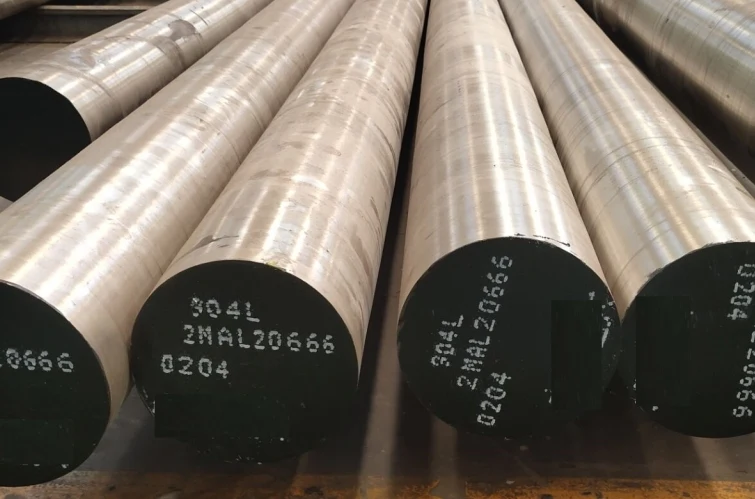

Source: Rolled Alloys

In the simplest words, 300 series stainless steels are specific stainless steel grades classified to be austenitic. Meaning, they have chromium content of about 18 to 30 percent and nickel for about 6 to 20 percent.

The term 300 series was derived and taken from the Society of Automotive Engineers (SAE), depicting the elements present in them. To help you, the SAE-AISI system classifies other alloys using the same index, and they are as follows:

- 1 – Carbon steels

- 2 – Nickel-based steels

- 3 – Nickel-chromium steels

- 4 – Molybdenum-based steels

- 5 – Chromium steels

- 6 – Chromium-vanadium steels

- 7 – Tungsten-chromium steels

- 9 – Silicon-manganese-based steels

Differences Between 300 Series Stainless Steels

Yes, they’re known to be 300 series because of their significant chromium and nickel content. However, not all grades share the same traits. They have unique properties that are for specific applications and uses.

The Most Common 300 Series Stainless Steels

There are many different alloys in the 300 series stainless steels. The following are considered and known to be the most common:

- 304 Stainless Steel: The most popular stainless steel is 304, which has outstanding strength, weldability, and corrosion resistance. It is perfect for architectural applications, food processing, and kitchen equipment.

- 316 Stainless Steel: 316 stainless steel has more molybdenum, which improves corrosion resistance, particularly in marine environments and against chlorides. Chemical processing, marine applications, and medical devices all frequently use it.

- 321 Stainless Steel: Similar to 304, 321 stainless steel is stabilized with titanium to stop the precipitation of carbide. In high-temperature settings like exhaust systems and aircraft, it is recommended.

- 347 Stainless Steel: Niobium is added to 347 stainless steel to increase stability and prevent intergranular corrosion. It is perfect for power plants and heat exchangers.

NOTE: Other 300 series steels include 301, 302, 309, 310, 318, 330, etc., all of which have varying ductility, weldability, and temperature resistance.

300 vs. 400 Series Stainless Steel: Which is Better?

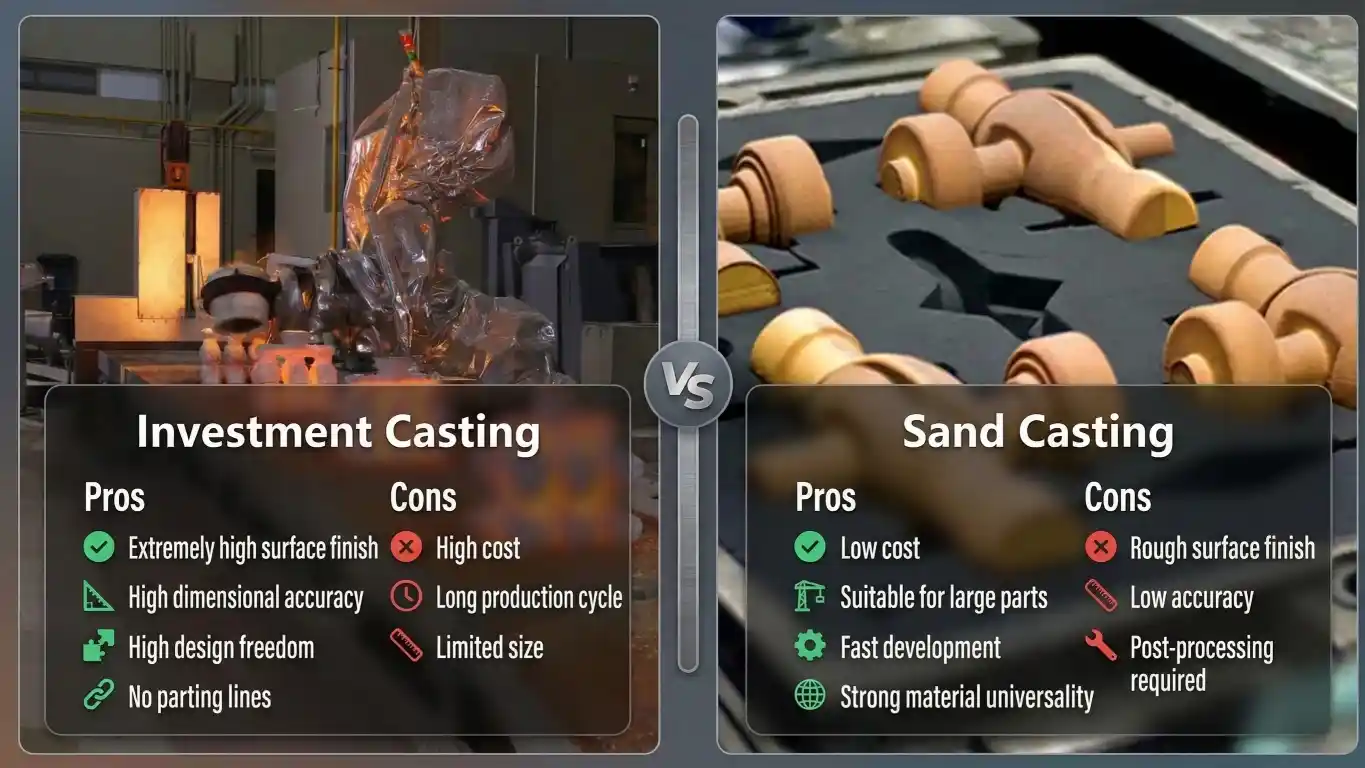

Source: YG Metals

Other than the 300 series, there are also other stainless steel grades that have varying features and properties. The most common series they’re usually put up against is the 400 series. They seem close, and they seem similar, but they are actually far from that.

Check this video out and see their differences!

Let’s look at this table and see how they’re different from one another!

| Feature | 300 Series Stainless Steel | 400 Series Stainless Steel |

| Composition | High chromium, high nickel (non-magnetic) | High chromium, low to no nickel (magnetic) |

| Corrosion Resistance | Excellent, especially in harsh environments | Moderate, less resistant to rust over time |

| Strength & Hardness | Softer but tougher, resists cracking | Harder but more brittle under stress |

| Heat Resistance | Performs well under high heat | Varies; some grades offer decent heat resistance |

| Common Uses | Food processing, medical, marine, aerospace | Automotive parts, cutlery, appliances, industrial tools |

Why HDC Manufacturing is the Best Manufacturer of 300 Series Stainless Steel

Stainless steels are categorized into different families, and then different grades. And, to tell you, not all manufacturers fit the narrative of being the best in all of those. But, what if I tell you that there is a supplier so focused in quality that can get you top-tier caliber stainless steel, whatever series it is?

Here at HDC Manufacturing, we value quality and standard more than anything else. We are equipped by the best people in the industry and have been investing in the best and most expensive resources.

You’ll never go wrong in choosing us here at HDC Manufacturing for 300 stainless steels, 400, or even whatever metal or alloy you need. If we have it in our arsenal, we’ll help you with it.