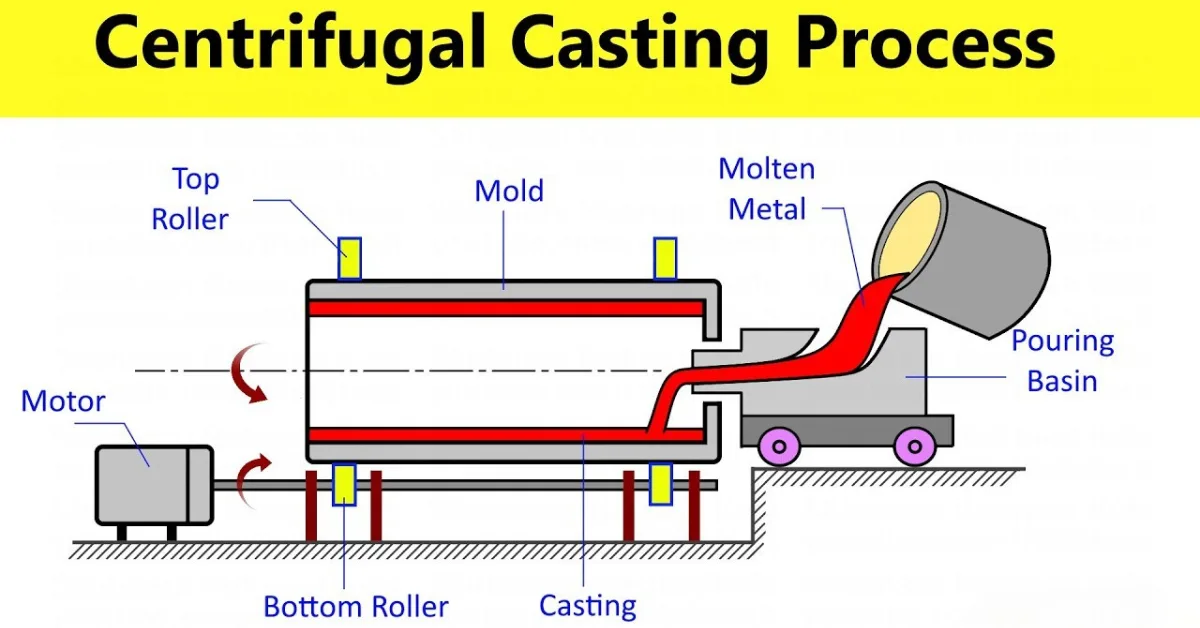

Have you ever thought about the precision of cylindrical parts like pipes and tubes? It is due to centrifugal casting. Centrifugal casting is a manufacturing method which uses rotational force. In this process, you pour molten metal in a fast spinning, pre heated mold. This centrifugal force pushes the metal into the mold’s wall. This technique removes many traditional casting limitations which ultimately reduces production costs significantly.

What is Centrifugal Casting?

Centrifugal casting is a smart way to make parts using spin. You pour hot, liquid metal into a mold that spins very fast. The outward push, called centrifugal force, spreads the metal evenly onto the mold’s walls. This force also pushes heavier, good metal outward and lighter flaws inward.

Why centrifugal casting?

Centrifugal casting comes with several advantages:

- Stronger Parts

- Hollow Parts Made Easy

- Better Quality

To get the best results, you must focus on two main things: spin speed and machine position. The mold must spin at the right speed. Fast molding can change the metal’s structure. Similarly, too slow mold will remain empty.

Detailed Process of Centrifugal Casting

Mold Preparation

Molds are cleaned and examined, and any contaminants from previous casts are removed from the mold. Refractory coatings applied to the mold surface prevent the metal from sticking, and prolong its life.

The next step is preheating the mold to a temperature that avoids thermal shock when the metal contacts the surface and improves the flow characteristics. You will check mold alignment before rotation begins.

Misalignment produces variations in wall thickness and mistakes in dimensions. This misalignment will be corrected in the spindle of the centrifugal machine. Then check that all the clamps and other fixtures are holding firm, as vibration causes casting defects.

Metal Melting and Pouring

The temperature of melting metals must be monitored and controlled, as the metal should be kept above certain liquidus temperatures. Avoid superheating to prevent gas absorption.

You will use induction furnaces, again depending on your volume. You will measure melt chemistry with spectrometers, and adjust alloy chemistry where necessary, before pouring. Degas the molten metal for removal of dissolved hydrogen and nitrogen then transfer the melt into a pouring ladle.

Pre-rotate the mold before pouring the molten metal first. The focus should be on steady state speed. The metal is then poured through a series of troughs at a controlled rate. Rapid pouring causes turbulence and oxide entrapment.

Slow pouring results in premature solidification. Therefore, maintain consistent flow throughout filling. Some operations use automated pouring systems for repeatability.

Solidification Under Rotation

Solidification happens while the mold continues rotating at controlled speed. Centrifugal force maintains metal contact with the mold wall. As a result, directional solidification progresses from the outer surface inward. This creates a fine grained outer layer with superior properties.

You will continue rotation until complete solidification finishes. Moreover, premature stopping causes sagging and distortion. The cooling rate influences grain structure development. In addition, faster cooling produces finer grains and higher strength. However, excessive cooling rates introduce residual stresses. Balance cooling time against production requirements and metallurgical targets.

Post-Casting Operations

Post casting operations begin after the part reaches handling temperature. First, remove the casting from the mold carefully. Then, separate any expendable mold materials. Next, trim excess metal from the casting ends using cutting tools. Machine the inner diameter to remove slag and impurity layers.

This step improves surface finish and dimensional accuracy. Afterwards, perform heat treatment if the alloy requires it. Heat treatment relieves residual stresses and optimizes mechanical properties.

Inspect dimensions using coordinate measuring machines. Then, you will check for surface defects through visual examination and non destructive testing. Finally, apply surface treatments such as machining, grinding, and coating.

Types of Centrifugal Casting

True Centrifugal Casting

Symmetric hollow parts are the result of true centrifugal casting. Additionally, it revolves around a central axis. The mould spins rapidly. It typically falls between 300 and 3000 rpm. The inner surface has no core and is only shaped by centrifugal force. This technique effectively shares cylinders, bushings, pipes, and tubes.

Both horizontal and vertical axis orientations are compatible with the process. Long pipe production is suited for horizontal machines. At the same time, vertical machines are better at handling shorter parts. The amount of metal poured into the mould determines the thickness of the wall.

Consistent thickness along the length is guaranteed by uniform rotation. This process is used by industries to create bearing sleeves, gun barrels, and pressure vessels.

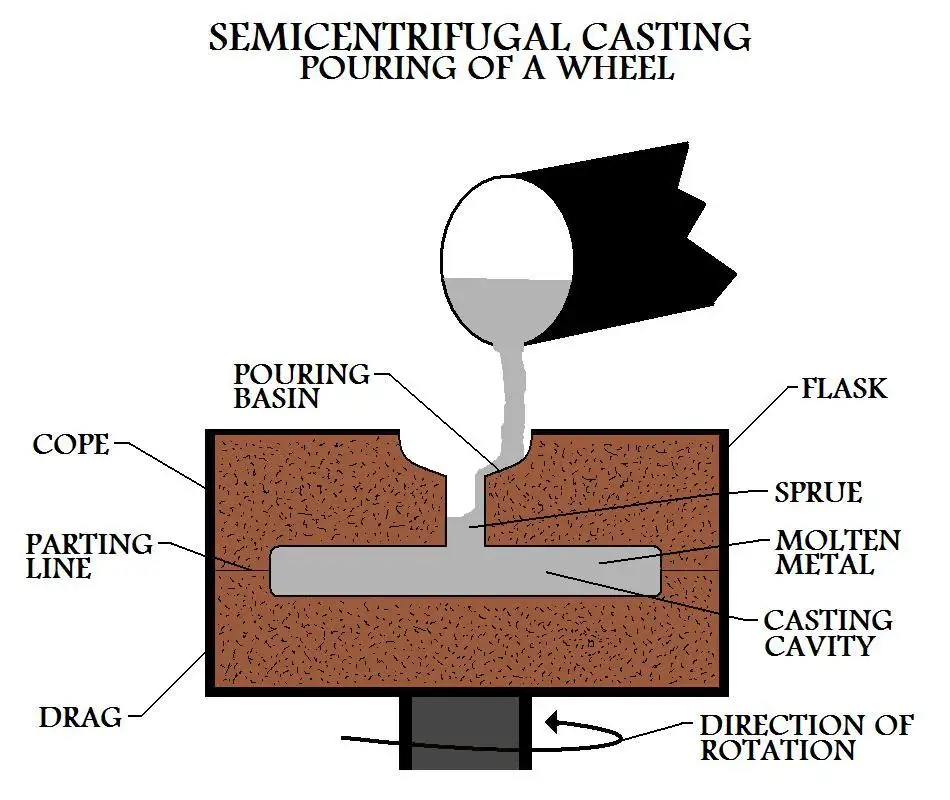

Semi-Centrifugal Casting

Semi centrifugal casting combines rotation with cores. The rotational axis passes through the part’s center of symmetry. However, the part has features beyond simple hollow cylinders.

Cores make internal passages. For instance, centrifugal force still improves metal feeding and reduces porosity. Similarly, rotation speeds remain lower than true centrifugal casting. It is 100 to 500 rpm. This technique produces wheels, pulleys, gears, and valve bodies.

Centrifuge Casting

A central sprue with numerous mould cavities spaced radially is used in centrifuge casting. The central axis is rotated by the entire assembly. Radial gates allow molten metal to flow from the sprue into individual moulds. During a single pour, a distinct component is produced in each cavity.

For small parts, this significantly boosts production efficiency. The moulds are fed by centrifugal force, which also minimises flaws. For rings, jewellery makers commonly use centrifuge casting. Additionally, dental labs use this technique to create crowns and bridges.

Process Parameters and Their Effects

Rotational Speed Optimization

Rotational speed directly affects casting quality and defect formation. Lower speeds cause incomplete filling and sagging. Higher speeds introduce segregation and hot tearing. Dense metals require lower rotational speeds than lighter alloys.

For instance, steel castings need 500 to 900 rpm depending on diameter. Aluminum requires 800 to1500 rpm for similar sizes. You should test different speeds during process development so you can identify optimal parameters.

Temperature Control

Temperature control affects both pouring and solidification phases. Pour temperature must exceed the liquidus point. Insufficient superheat causes premature freezing during mold filling. Similarly, excessive temperature increases shrinkage and gas absorption.

Mold temperature influences solidification rate and thermal gradient. For example, higher mold temperatures slow cooling and produce coarser grains. Lower temperatures accelerate solidification and refine microstructure.

You should match mold temperature for casted alloy. Thick walled parts benefit from higher mold temperatures that reduce thermal stress. And thin walled parts need lower temperatures for adequate feeding.

Wall Thickness and Dimensional Control

Wall thickness varies with metal volume and rotational parameters. Calculate the required metal weight based on desired thickness and part dimensions. The formula incorporates three factors:

- Metal density

- Centrifugal force

- And mold geometry.

Thicker walls require more metal and longer solidification times. On the other hand, thinner walls demand precise pouring control and higher rotational speeds.

Dimensional accuracy depends on mold precision and thermal expansion coefficients. Metal shrinks during cooling. It also affects final dimensions. Compensate for shrinkage by oversizing mold dimensions appropriately.

You can measure shrinkage rates for each alloy through testing. You will also adjust mold dimensions accordingly to achieve target specifications.

Materials and Metallurgical Importance

Ferrous Materials Processing

Ferrous materials include various steel grades and cast irons. Gray iron casting produces parts with excellent wear resistance. The centrifugal process concentrates graphite flakes toward the inner surface. Ductile iron develops spheroidal graphite through magnesium treatment before casting.

Centrifugal force improves nodularity and mechanical properties. For instance, steel alloys require careful temperature management. The reason is its narrow solidification ranges. Stainless steels have low porosity in casting which is a good sign.

Alloy steels have good strength and toughness if you compare it with static casting. Control carbon content carefully because segregation concentrates it inward.

Non-Ferrous Materials Processing

Non ferrous materials encompass aluminum, copper, and specialty alloys. Aluminum alloys cast easily due to low melting temperatures. Subsequently, silicon content affects fluidity and feeding characteristics. Copper alloys including bronze and brass produce high quality bearings.

Centrifugal force removes porosity because it weakens bearing surfaces. Nickel based superalloys require high pouring temperatures and special mold materials. These alloys are used in aerospace and power generation sources.

Microstructure Development

Microstructure development depends on solidification rate and thermal gradients. Rapid cooling at the mold surface creates fine equiaxed grains. Slower cooling toward the inner surface produces columnar grain growth. This creates a gradient structure with different properties through thickness.

The outer surface shows higher hardness and strength. Inner regions will give you better ductility and toughness. Centrifugal force also influences dendrite arm spacing. Moreover, finer spacing improves mechanical properties. You can control cooling rate through selecting mold material and managing temperature.

Advantages of Centrifugal Casting

Centrifugal casting removes cores for hollow parts completely. This reduces costs and makes mold design easy significantly. Furthermore, centrifugal force feeds the solidifying metal regularly. Hence, shrinkage porosity decreases compared to gravity casting. The process produces superior surface finish on the outer diameter.

Machining requirements reduce accordingly. For example, it saves time and money. Furthermore, impurities also migrate toward the inner surface. Machining removes this contaminated layer easily and it happens during finishing operations.

You will see that dense, sound castings come from proper parameter control. Mechanical properties often cross forged parts in some applications. Also, production rates increase because multiple parts cast simultaneously on one machine.

Material yield also improves since gates and risers become unnecessary. Flexibility will allow you to produce various diameters. For example, they can use the same equipment with different molds.

Applications of Centrifugal Casting

Centrifugal casting is used in many industries especially that require cylinder shaped parts. Pipe manufacturing for water, oil, and gas distribution depends heavily on this process. These pipes give you excellent pressure resistance.

Engine cylinder liners use centrifugal casting to fight against wear resistance and dimensional stability. Meanwhile, bearing bushings are the result of a dense outer surface that resists friction.

Rolling mill rolls require large diameter cylinders with uniform hardness distribution. Paper mill rolls similarly demand consistent surface properties for quality production. Pressure vessels for chemical processing face high internal pressures safely.

Artillery gun barrels also get better strength and accuracy that is crucial in the military.

Defects, Causes, and Prevention

Common Defects

You will see many defects in this process. The most common reason is the parameters deviate from the best range.

Banding appears as circumferential layers of varying composition. This is the result of segregation during solidification under rotation. Hot tears develop when restrained contraction creates tensile stresses.

They appear as cracks in the casting surface. Inclusions concentrate toward the inner diameter but sometimes trap in the metal.

In addition, surface roughness increases when mold coatings wear out. Furthermore, dimensional variations occur due to the inconsistent rotational speed.

Quality Control Methods

Your quality control starts from the raw material. You will verify and inspect its quality. You can test incoming metals for chemical composition and purity levels. Also double check molds for cracks, wear, and coating before each use.

Monitor process parameters continuously during casting operations. Record rotational speed, temperatures, and timing for traceability. Perform visual inspection immediately after casting removal. Look for surface defects, cracks, and dimensional irregularities.

Conduct non-destructive testing using ultrasonic or radiographic methods. These reveal internal porosity, inclusions, and structural discontinuities. Machine test samples to verify wall thickness and inner surface quality.

Perform mechanical testing on representative specimens periodically. Measure hardness, tensile strength, and impact toughness against specifications. Similarly, do not forget to document all results and maintain statistical process control charts.

Conclusion

Centrifugal casting gives you high quality cylinder parts. However, there are issues that you should meet before making any part. Also, you have learned how to select materials, and their different applications. If you apply proper parameter control, you can easily handle defect free castings.

FAQs

How to calculate correct rpm in centrifugal casting?

RPM calculation depends on the G force and mold diameter. The common formula to calculate rpm in centrifugal casting is RPM = √(G × 1000 / R).

Why does centrifugal casting need inner diameter machining?

The inner diameter in centrifugal casting gives lighter impurities. They migrate inward due to centrifugal force. It is also called secondary refining. The ID requires machining allowances typically ranging from 3-10mm. The purpose is to remove these impurities and achieve specified dimensions.

What are the size limitations for centrifugal casting?

Vertical centrifugal casting has length-to-diameter ratios limitations. And it is approximately 2:1 due to gravity effects. These effects cause parabolic bore formation. However, horizontal centrifugal casting does not face this issue. Therefore, it can produce tubes up to 15 meters long and 6 meters in diameter.