Whether you’ve heard about it or not, CF8M seems and sounds peculiar to be a stainless steel grade. But when you know about it, you’ll be surprised at what it is and how common they’re used in various subsets of industries.

In this article, we’ll go in-depth into understanding CF8M more. We’ll discuss what CF8M is, what makes it one of the more special stainless steel types, and more!

What is CF8M?

Source: NJXS Alloy Steel

CF8M is a cast austenitic stainless steel that belongs to the ASTM A351 standard. It’s a 316 stainless steel cast equivalent, with molybdenum added for better corrosion resistance, especially against chlorides and acidic environments.

This composition makes it an ideal option for valves, pumps, and fittings used in chemical processing, marine, and food industries.

NOTE: These are just some of the most common uses of CF8M, but they’re not everything. There are a lot more things you can do with it, which we’ll dive deep into later.

CF8M Stainless Steel Characteristics, Properties, and More

CF8M is a cast austenitic stainless steel, equivalent to wrought AISI 316. It’s a superalloy known for its excellent corrosion resistance and mechanical properties.

Source: CFS Foundry

Furthermore, CF8M is heavily used in various industries, particularly in chemical processing, marine applications, food processing, and others; particularly where durability, longevity, and resistance to corrosive environments are essential.

CF8M Chemical Composition

First, let’s start with composition. To further understand CF8M, we need to gain a better understanding of what makes it as it is.

The chemical composition of CF8M stainless steel is carefully balanced to enhance its performance:

- Chromium (Cr): 18.0% to 21.0%

- Nickel (Ni): 9.0% to 12.0%

- Molybdenum (Mo): 2.0% to 3.0%

- Carbon (C): 0.08% maximum

- Manganese (Mn): 1.5% maximum

- Silicon (Si): 1.5% maximum

- Phosphorus (P): 0.04% maximum

- Sulfur (S): 0.04% maximum

NOTE: The addition of molybdenum strengthens the resistance to crevice, pitting, and corrosion, particularly in chloride-rich environments. The low carbon content minimizes carbide precipitation during welding, reducing susceptibility to intergranular corrosion

Mechanical Properties

Now that we know about its composition, let’s take a step back and try unraveling some of CF8M’s mechanical properties.

It’s quite evident that the combination of strength, ductility, and resistance makes it an excellent option for very specific applications. But what about their mechanical properties? How good are they?

- Tensile Strength: Approximately 540 MPa (79 ksi)

- Yield Strength: Around 290 MPa (42 ksi)

- Elongation at Break: Approximately 50%

- Brinell Hardness: Approximately 170

Temperature Resistance and Melting Point

The mechanical characteristics of CF8M are maintained over a broad temperature range:

- Operating temperature maximum: up to 815°C (1500°F)

- Range of Melting Point: roughly between 1400°C and 1440°C (2550°F and 2620°F)

This high-temperature resistance and capability makes CF8M ideal for applications with extreme temperatures like furnace components, valves, and heat exchangers.

Density

And last but most definitely not least is the density of CF8M stainless steel. The density of CF8M stainless steel is approximately 7.8 g/cm³ (490 lb/ft³), which is typical for austenitic stainless steels.

This largely contributes to the robustness and suitability for structural applications.

There you have it! The more important factors, characteristics, and components of CF8M stainless steel. Understanding these will help you figure out how they’re better and how they’re performing in several instances and situations.

CF8M Applications and Uses

Source: Walkson

To grasp the idea of how common CF8M stainless steel is. Here are some of the industries of applications where they’re often used.

- Oil & Gas Industry

- Chemical Processing

- Food and Beverage

- Electricity and Power Generation

- Marine and Shipbuilding

- Water Treatment

- Medical and Pharmaceutical Industries

- And Many More!

CF8M vs. 316 Stainless Steel

Both CF8M and 316 stainless steel are corrosion-resistant alloys, but serve different purposes.

CF8M is a cast version of 316 stainless steel, making it better suited for complex shapes like pump housings and valve bodies. On the other hand, 316 stainless steel is wrought, meaning it has better mechanical properties for applications requiring higher strength and formability.

Check out this comparison table between CF8M and 316 stainless steel to further your knowledge of these two types!

| Property | CF8M Stainless Steel | 316 Stainless Steel |

| Composition | Cast version of 316, slightly more molybdenum | Wrought alloy, better uniformity |

| Corrosion Resistance | Excellent in marine and chemical environments | Very high, especially in chloride exposure |

| Strength | Good, but lower than 316 | Higher tensile and yield strength |

| Formability | Limited due to casting | Easier to machine, bend, and weld |

| Applications | Valves, pumps, fittings | Structural components, pipes, medical tools |

Can CF8M Rust?

The short and easy answer is yes – CF8M can still develop rust as it is only “highly-resistant” to corrosion, not 100% rust-proof. Because of its high chromium and molybdenum content, CF8M stainless steel is resistant to rust, but not totally so.

CF8M can eventually develop surface corrosion or pitting in harsh environments, such as those with high chloride exposure or acidic conditions.

In addition to that, rust formation can also develop, and these may result from inadequate passivation, contamination, or poor maintenance.

But, unlike other metals and alloys, CF8M maintains high corrosion resistance and works well in demanding applications with the right maintenance and routine cleaning.

Why You can Get the Best-Quality CF8M from HDC Manufacturing

Our team of experts and professionals here at HDC Manufacturing is equipped with the necessary skills and experience to work on CF8M and other adjacent metals and alloys. For more than a decade, our mastery in the metal industry improved, and now, we’re China’s go-to option when it comes to CF8M steel.

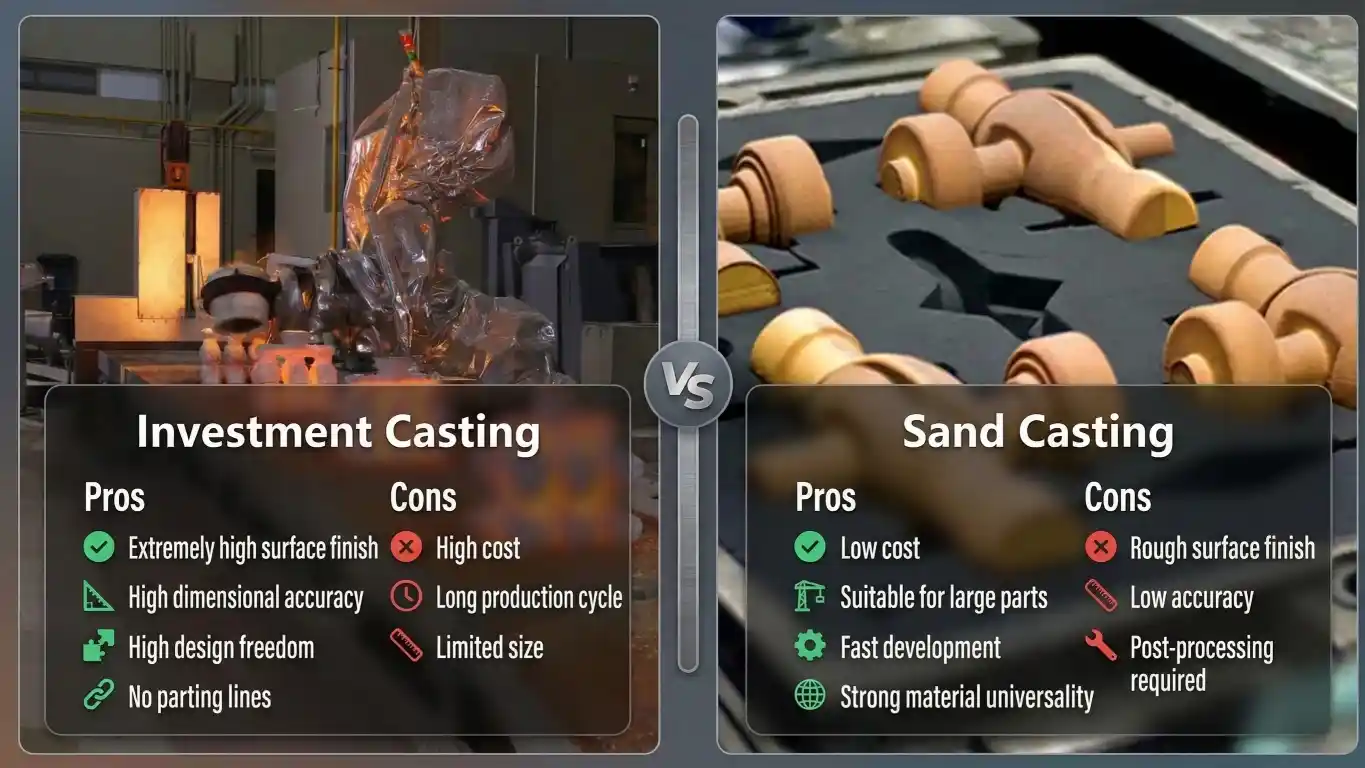

Besides typical processing and manufacturing, you can also bank on us for investment casting. That basically means that we’re skilled in processing Monel 400, A286, Hastelloy, and more!

If you’re looking for a company that you can trust for whatever metal processing, contact us! Send us a message and get a free estimate!