What is Low-Volume Manufacturing and Its Importance in Custom Products

Low-volume manufacturing has become a crucial approach in today’s dynamic market, enabling the creation of custom designs and custom products that cater to specific customer needs. Unlike traditional mass production, it focuses on smaller batches, allowing for the development of personalized products with unique specifications. This method is essential for businesses aiming to offer customized products, quickly respond to market changes, and serve niche markets. By prioritizing customization and quality, low-volume manufacturing delivers custom items that reflect individual preferences and innovative custom and design solutions.

Understanding Low-Volume Manufacturing

Low-volume manufacturing is a specialized production approach that focuses on creating smaller quantities of products compared to traditional mass production. Unlike large-scale operations that prioritize volume over variety, this method enables the production of custom items with unique specifications. This adaptability allows businesses to offer custom products that cater to specific market demands and customer preferences. By prioritizing quality and flexibility, low-volume manufacturing ensures that each item meets the precise needs of the client, whether it’s a limited-edition run or a bespoke component.

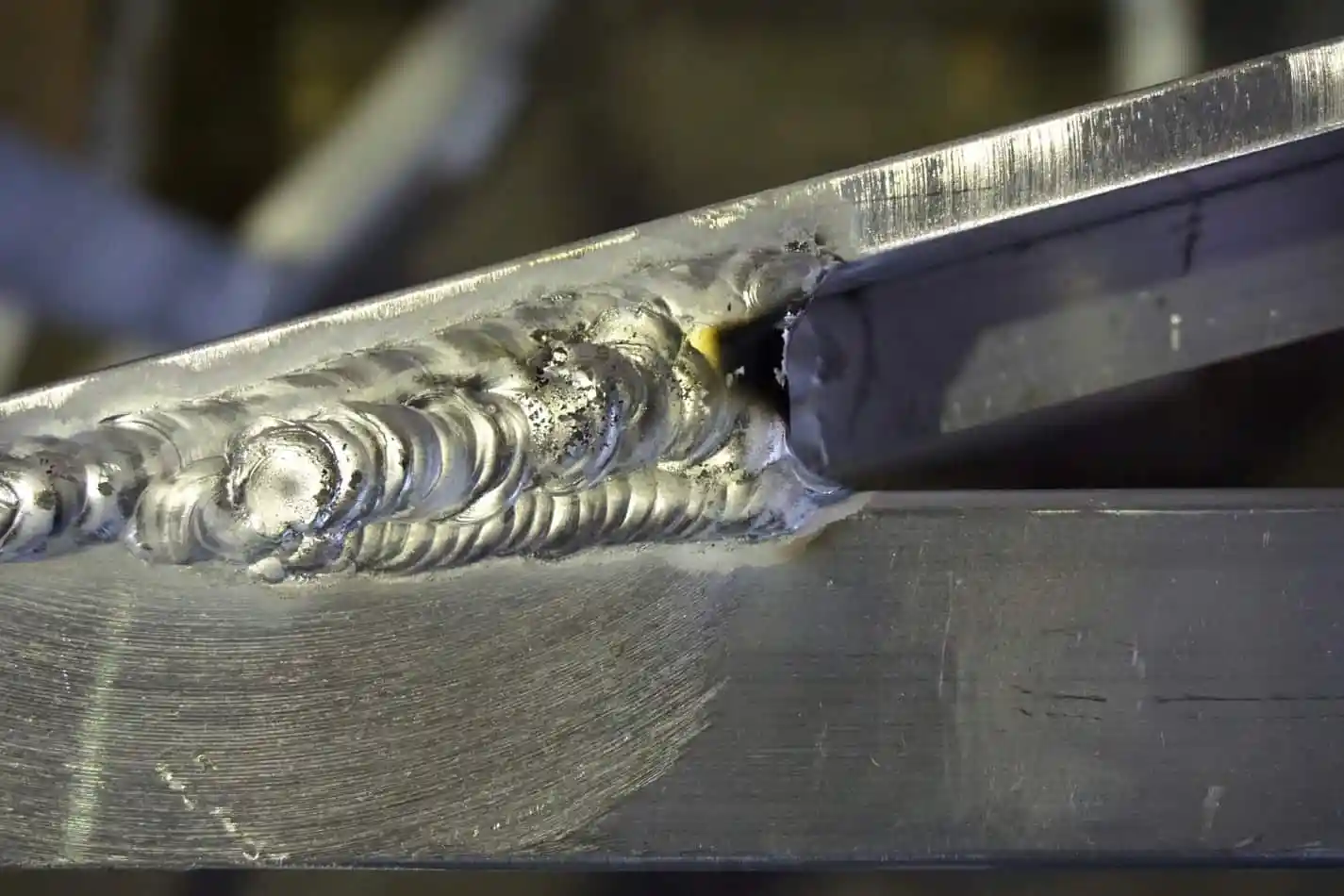

The techniques involved in low-volume manufacturing are diverse and advanced, making it ideal for crafting personalized products. CNC machining and 3D printing are among the most prominent methods, providing precision and versatility in the production process. These technologies enable manufacturers to create custom designs efficiently, turning intricate concepts into tangible customized products. Whether it’s a prototype or a fully functional part, low-volume manufacturing leverages cutting-edge processes to deliver custom and design solutions that stand out in the marketplace.

Benefits of Low-Volume Manufacturing

Low-volume manufacturing offers numerous advantages that make it an ideal choice for businesses seeking custom and design solutions tailored to their unique needs. One of the primary benefits is its flexibility and customization. This approach allows manufacturers to produce custom items that meet specific client requirements, accommodating changes and modifications without the constraints often associated with mass production. By offering the ability to quickly adapt to client needs, low-volume manufacturing ensures that businesses can deliver personalized products that stand out in a competitive market.

Another significant advantage is cost-effectiveness. Producing custom items in smaller quantities reduces material waste and minimizes financial risk. Businesses can avoid the large upfront costs and excess inventory associated with high-volume production, making low-volume manufacturing a smart choice for companies looking to optimize their budgets while still offering high-quality custom products.

Speed to market is another critical benefit of low-volume manufacturing. With shorter production cycles and faster turnaround times, businesses can quickly bring customized products to market, responding promptly to customer demands and market trends. This agility allows companies to stay ahead of the competition by launching personalized products that align with current consumer preferences.

Lastly, quality assurance is enhanced through smaller production runs. The focus on precision and attention to detail ensures that each product meets the highest quality standards. This results in superior customized products that reflect the craftsmanship and care put into their creation. By maintaining stringent quality control measures, low-volume manufacturing guarantees that every item is produced to exact specifications, satisfying even the most discerning clients.

Importance in Custom Products

Low-volume manufacturing plays a crucial role in the realm of custom products, offering unparalleled opportunities for customization and personalization. It empowers businesses to deliver custom designs that align perfectly with specific customer demands. By focusing on smaller production runs, manufacturers can produce personalized products that reflect individual preferences and requirements, ensuring that each item is uniquely tailored to the client’s vision. This level of customization fosters a deeper connection between the product and the consumer, enhancing brand loyalty and customer satisfaction.

A key aspect of low-volume manufacturing is its significant role in prototype development. This approach allows businesses to create and test prototypes efficiently, enabling multiple design iterations and refinements before moving to full-scale production. This iterative process helps identify potential improvements and ensures that the final product meets all necessary specifications and quality standards. By using low-volume manufacturing for prototypes, companies can confidently bring customized products to market that are both innovative and reliable.

Additionally, low-volume manufacturing is particularly well-suited for serving niche markets. These markets often require specialized custom and design solutions that aren’t feasible with traditional mass production methods. The flexibility and adaptability of low-volume manufacturing enable businesses to address the unique needs of these markets, producing custom items that cater to specific applications and preferences. This ability to serve niche markets opens up new business opportunities and allows companies to differentiate themselves in a crowded marketplace by offering truly bespoke solutions.

Key Technologies Used in Low-Volume Manufacturing

Low-volume manufacturing leverages several advanced technologies to produce customized products with precision and efficiency. CNC machining is a cornerstone of this approach, offering high precision and material versatility for creating custom items with intricate designs. 3D printing further enhances the process by enabling rapid prototyping and the development of complex custom designs that would be difficult with traditional methods. Additionally, injection molding is adapted for small batches, providing a cost-effective solution for producing high-quality custom products with consistent detail. Laser cutting and engraving offer precision cutting for custom and design solutions, allowing for intricate patterns and efficient material use. Finally, waterjet cutting provides an environmentally friendly option that cuts a wide range of materials without thermal distortion, making it perfect for crafting personalized products that meet specific customer demands.

What Industries Benefit from Low-Volume Manufacturing?

Low-volume manufacturing offers significant advantages to a wide range of industries that prioritize customized products and personalized solutions. The automotive and aerospace sectors rely on this approach for producing custom items like intricate components and prototypes, allowing for rapid design iterations and testing. The medical industry benefits from creating custom designs for surgical instruments and implants tailored to individual patients. In consumer electronics, low-volume manufacturing enables the production of custom products that cater to niche markets with specific design requirements. Additionally, the fashion and jewelry industries leverage this method to create personalized products that meet unique customer demands, enhancing brand appeal. Whether it’s producing specialty parts for custom and design applications or crafting bespoke items for discerning clients, low-volume manufacturing provides the flexibility and innovation needed across diverse fields.

How Does Low-Volume Manufacturing Benefit Startups?

Low-volume manufacturing offers significant advantages to startups by enabling them to produce customized products without the financial burden of mass production. This approach allows startups to create custom items and personalized products in smaller quantities, making it easier to test the market and refine their custom designs based on real customer feedback. The flexibility and speed of low-volume manufacturing also mean that startups can quickly adapt to changing market demands, bringing custom and design innovations to market faster than competitors. Additionally, by minimizing inventory costs and reducing waste, this method helps startups allocate their resources more efficiently, allowing them to focus on growth and innovation while delivering high-quality, custom products that meet the unique needs of their target audience.

What Are Common Challenges in Low-Volume Manufacturing?

While low-volume manufacturing offers numerous benefits, it also presents certain challenges that businesses must navigate. One major challenge is the higher cost per unit compared to mass production, as economies of scale are not as easily achieved when producing custom items in smaller quantities. Additionally, sourcing materials and components for custom designs can be more complex and costly, as suppliers often prioritize larger orders. Ensuring consistent quality in customized products is another hurdle, requiring precise attention to detail and rigorous quality control measures. The need for specialized skills and equipment to handle personalized products can further complicate the process, potentially leading to longer lead times and increased production costs. Despite these challenges, businesses that effectively manage these aspects can successfully leverage low-volume manufacturing to create innovative custom products that meet specific customer demands.

HDC’s Expertise in Low-Volume Manufacturing

At HDC, we specialize in low-volume manufacturing, offering a range of cutting-edge technologies tailored to meet diverse client needs. Our capabilities include various CNC techniques, such as precise Swiss screw machining for small-sized products and advanced 5-axis CNC machining. We also excel in laser cutting, injection molding, laser engraving, and 3D printing, making us a leader in custom and design solutions. Our extensive material offerings cater to custom metal products and plastic products, featuring metals like aluminum alloy, stainless steel, carbon steel, alloy steel, titanium alloy, copper, brass, magnesium, Inconel, Stellite, and Hastelloy. Our plastics include common materials such as nylon, PVC, POM, and HDPE. With a robust custom product process and specialized quality control equipment, we are committed to delivering exceptional customized products and services. Our expertise extends to providing custom metal parts for industries including automotive, trailers, go-karts, bicycles, and motorcycles. While we also offer stainless steel investment casting and aluminum forging—techniques typically used in larger productions—these methods remain the best choices in specific scenarios. For detailed information about our custom services, please visit our Customization Support & Service Policy page.

Conclusion

Low-volume manufacturing is a powerful solution for businesses looking to create customized products that meet specific customer needs. With its flexibility, cost-effectiveness, and ability to rapidly bring custom items to market, this approach is invaluable for startups and established companies alike. By leveraging advanced technologies and diverse materials, businesses can craft personalized products that stand out in competitive markets. Whether you’re looking to test a new custom design, serve a niche market, or ensure high-quality production, low-volume manufacturing offers the perfect blend of innovation and efficiency. For those interested in exploring the possibilities of custom manufacturing, HDC is ready to provide expert guidance and support tailored to your unique requirements.