Normalizing is a form of metal heat treatment used to refine grain structure. It is typically performed after another manufacturing process has reduced ductility.

Whether you’re an experienced metalworker or a student, keep reading. This guide reveals the advantages of normalizing. Along the way, we cover key normalizing parameters and examples of normalized steel appliances.

How the Normalizing Process Works

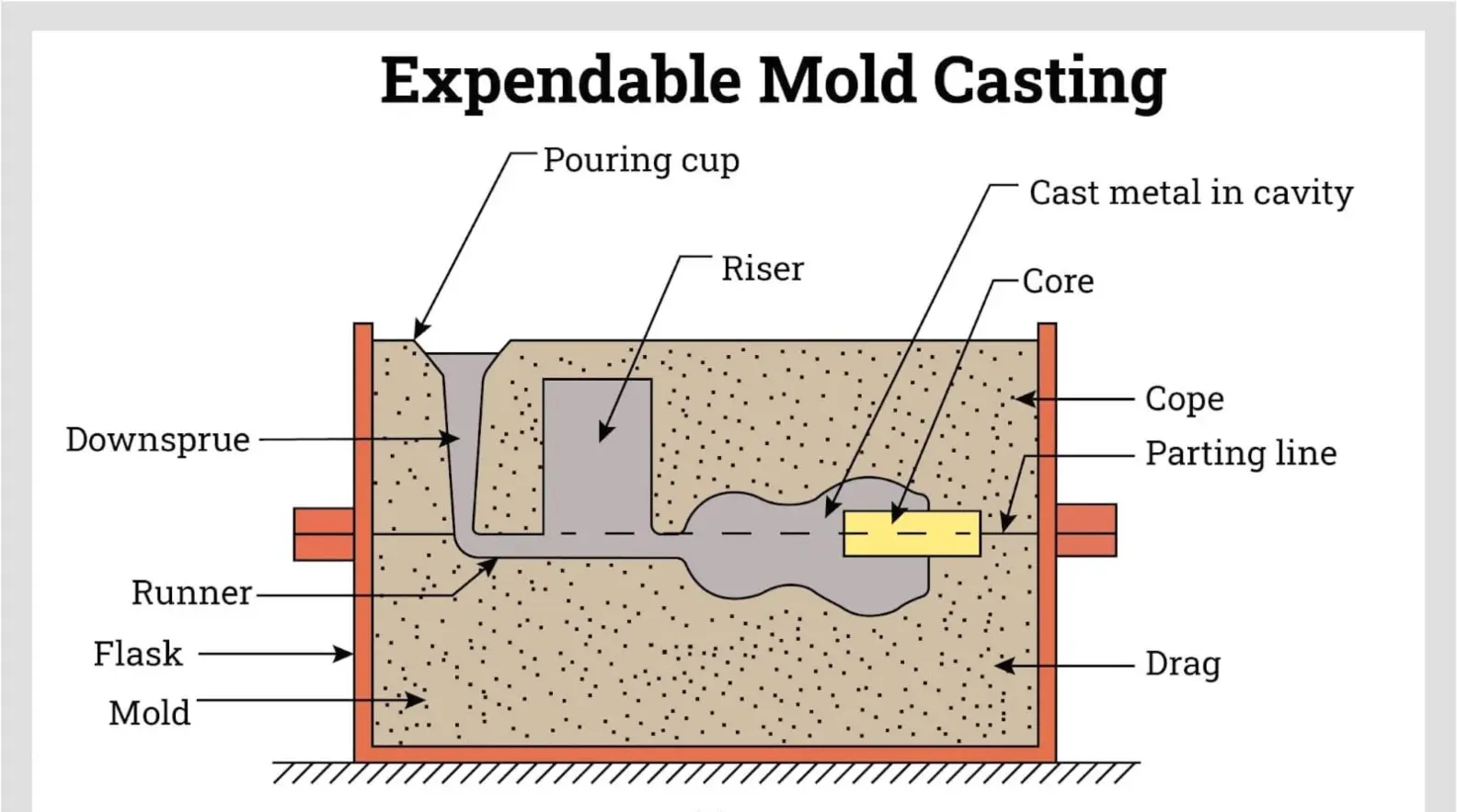

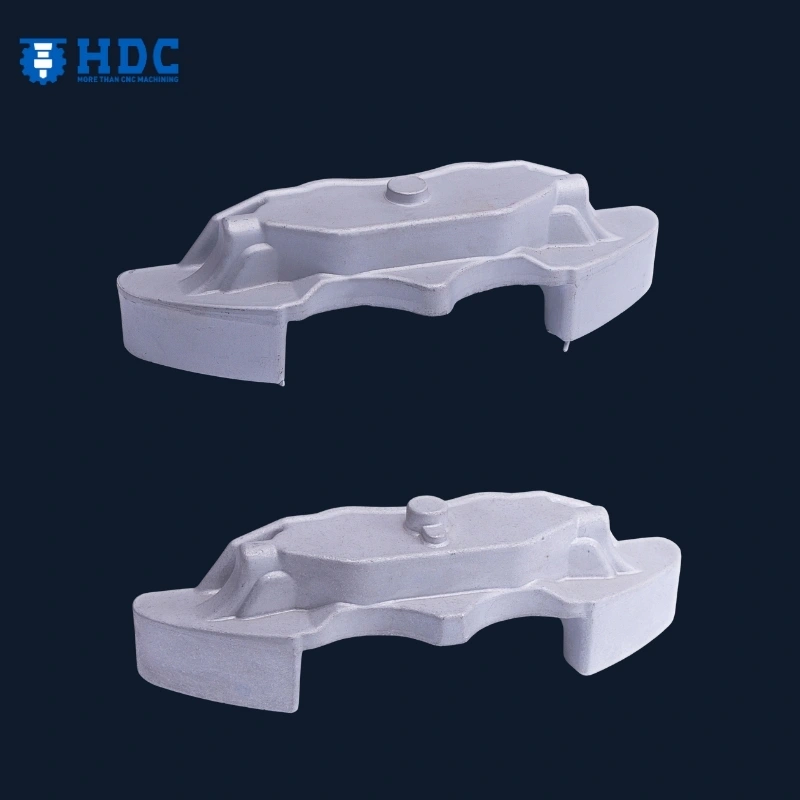

Normalizing is performed after fabrication techniques such as stamping or casting. This is because metals that have been quenched for hardness typically exhibit reduced ductility.

Normalizing transforms your metal’s crystal structure to a ductile state, enhancing toughness and brittleness. Consequently, normalized steels and nickel alloys are easier to machine than their untreated counterparts. Normalizing also prevents failures by relieving residual stress.

Now that you know the purpose of normalizing, it is time we cover key normalizing parameters.

Heating

To perform normalizing, heat your metal to its upper critical temperature. Recovery begins in this stage as defects in the microstructure undergo refinement. This leads to the progressive relief of stresses picked up during other manufacturing processes.

If you are normalizing steels yourself, the big challenge is getting your entire workpiece to heat evenly. Uneven heating produces a metal with inconsistent properties, which later show up as failures in machining or service.

Soaking Time

Once you have heated the steel sufficiently, the next step is to hold it at recrystallization temperature for a predetermined period. During this hold, the mechanical properties change. The longer it is held, the more its properties alter.

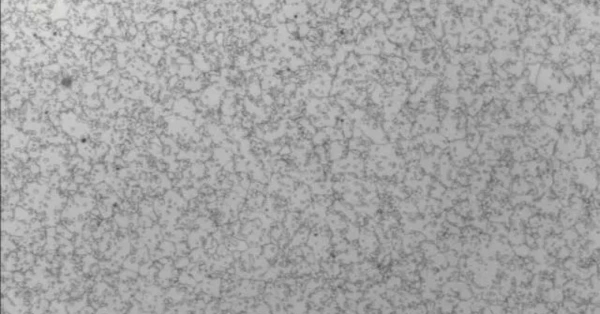

As the recrystallization point is reached, bainite and carbides dissipate from the metal. New austenitic grains form, consuming existing dislocations, grain boundaries, and defects. These grains are smaller in size than previous ferritic grains. For more details, you can check the guide on the structure of engineering metals.

Cooling

The last stage of normalizing is the grain growth stage. This growth is controlled by cooling the heated metal in air until it reaches room temperature. Those newly formed grains we just mentioned fully evolve and mature, producing a metal that is strong and ductile.

During cooling, you must carefully monitor the cooling rate. The slower the cooling, the more toughness your metal will exhibit. Likewise, the faster the cooling, the more harndess your metal will exhibit.

Which metals can be normalized?

You can perform normalizing on several types of metals. These include:

- Iron alloys

- Nickel alloys

- Aluminium

- Copper

- Brass

Effects on Material Properties

In this section, you learn about the effect of normalizing on the properties of steel.

Microstructural Improvements

When steel is heated during normalizing, the microstructure changes into austenite. After it cools in the air, austenite transforms into ferrite and pearlite, which exhibits a uniform grain. Compared to untreated or slowly cooled steel, the grains are smaller and more even.

Mechanical Properties

Normalizing enhances the toughness of steels by altering grain structure. This means your appliances will withstand greater forces without fracturing. Normalized steels also perform better under repeated stresses, which is important for high-stress shafts, gears, and welded parts.

Normalizing vs. Annealing

In this section, you learn about the difference between normalizing and annealing.

Cooling Differences:

One major difference between annealing and normalizing is the rate of cooling. During normalizing, we cool the material in still air to produce a fine and tough grain structure. On the other hand, the workpiece is slowly cooled inside the furnace during annealing. The result is a coarse-grained microstructure and a metal that is very ductile and soft.

Resulting Properties:

Due to the slower cooling rate, annealed steel is softer and more ductile. This makes it the superior choice for forming and high-speed CNC machining. In comparison, normalized steel is harder and stronger than its annealed counterpart. Therefore, it finds application in industries that require exceptional strength.

Cost & Efficiency:

Due to more time in the furnace, annealing is more costly than normalizing. Furthermore, it requires more energy to reach and maintain elevated temperatures. For more details, you can check the guide on annealing.

If you are just getting your feet wet in metallurgy, it is easy to confuse normalizing with annealing. After all, they appear to be identical processes. Heat your metal above the critical point, hold it for a given time interval, then cool it off to achieve your desired properties.

Except the difference lies in what we’re trying to achieve. If you need to refine your steel’s structure for increased performance, then normalizing is the way to go. Whereas, if you need to soften your metal before machining or cold work, annealing is the superior choice.

Why Use Normalizing? Key Benefits

Normalizing heat treatment offers metal workers the following benefits:

- Relief of residual stress: During normalizing, defects from welding, quenching, etc begin to dissipate. The result is a crystalline structure that is free of residual stress.

- Increased ductility: Since normalizing leads to uniform grain structures, it helps make metals more ductile.

- Improved machinability: Through normalization, you can alter your metal to make it more machinable and formable.

Typical Applications and Industries

Below are the typical applications and industries in which normalizing is commonly used.

- Automotive: If you work in automotive, you can normalize ferritic steel stampings to reduce the hardness acquired during forming.

- Work hardening: You can perform normalizing to enhance the brittleness of carbon steel after cold rolling.

- Nuclear: Normalizing proves to be useful in the nuclear industry. Manufacturers perform normalizing on nickel alloys to reverse microstructure changes caused by welding.

Summary Comparison Table

The differences between annealing, normalizing, and quenching are shown in the table below.

Process | Cooling Method | Key Advantages | Typical Outcome |

Annealing | Slow (furnace) | Maximum ductility, soft metal | Soft, ductile, homogeneous microstructure |

Normalizing | Air cooling | Balanced strength, faster, cost-effective | Fine grains, improved toughness/stability |

Quenching | Rapid (water/oil) | High hardness | Hard, brittle microstructure |

Conclusion

In conclusion, metals are typically normalized after another manufacturing process e.g quenching has reduced ductility. It is one of the methods for removing residual stresses and improving metal ductility. Not sure where to begin? HDCMfg is happy to assist you with any technical matter.

Discover more with our blog posts.

Recent Posts

Discover more about our products

HDC Products

Instant Quote!