Precision Titanium Alloy Manufacturing & CNC Machining Services

At HDC, we specialize in high-performance titanium alloy components crafted to meet the most demanding industrial standards.

Why Choose Titanium

Superior Strength-to-Weight Ratio

Unmatched Corrosion Resistance

Biocompatibility & Longevity

Why Partner With HDC

Comprehensive Titanium Material Options

Certified Materials & Compliance

Advanced Machining & 3D Printing

Strict Quality Control and After-Sales Support

Design & Engineering Expertise

Competitive FOB Pricing & Logistics

Titanium Selection Guide

Choosing the right titanium alloy is critical to balancing strength, corrosion resistance, and cost-efficiency for your application. Below, we break down key properties of titanium alloy to simplify your decision-making:

Need Help? Contact our engineers for material recommendations.

Grade 5 (Ti-6Al-4V)

| Composition | Ti-6Al-4V |

| Density | 4.43 g/cm³ |

| Melting Point | 1604–1660°C |

| Tensile Strength | 895–930 MPa |

| Corrosion Resistance | Good (resists acids, chlorides) |

| Recommended Processes | 5-axis machining, DMLS 3D printing |

| Avoid | Arc welding without post-annealing |

| Applications | Aerospace fasteners, medical implants |

Our Precision Manufacturing Capabilities

From prototyping to mass production – optimized for titanium's unique properties

CNC Turning

Key Specs:

±0.01mm tolerance

Max part diameter: Ø150mm

Surface roughness: Ra 0.8μm

Ideal For:

High-volume cylindrical components.

Threaded parts (M3–M20 threads).

5-Axis CNC Machining

Key Specs:

±0.005mm tolerance

Max part size: 600×400×300mm

Ideal For:

Aerospace brackets & turbine blades.

Medical implants.

Swiss Screw Machining

Key Specs:

±0.005mm tolerance

Part diameter: Ø0.5–32mm

Ideal For:

Miniature fasteners (screws, pins).

Connectors for electronics & medical devices.

Titanium 3D Printing (DMLS)

Key Specs:

Layer thickness: 20–60μm

Max build size: 250×250×325mm

Ideal For:

Aerospace brackets.

Custom orthopedic implants with lattice structures.

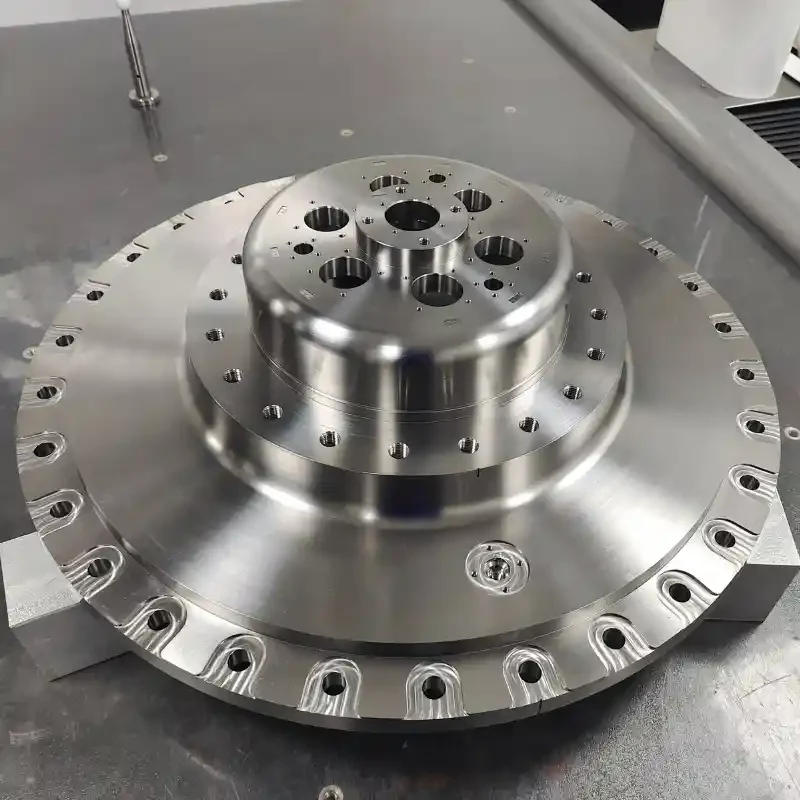

Titanium Products Showcase

Explore our diverse range of high-quality titanium products, designed to meet the exacting standards of various industries.

5 Axis CNC Machining Titanium Parts

5 Axis CNC Machining Titanium Impeller

CNC Machining Titanium Suspension Patrs

FAQ

To provide an accurate quote, we need detailed design drawings or sketches, material specifications, quantity, and any specific requirements or tolerances.

Cost: Titanium is 3–5x more expensive than aluminum and 2–3x pricier than stainless steel, but offers unmatched strength-to-weight ratios.

Performance: 2x stronger than aluminum, 45% lighter than steel, and resists corrosion in seawater/acidic environments.

Compliance: AS9100 (aerospace), ISO 13485 (medical), ISO 9001, and RoHS/REACH.

Documentation: Material Test Reports (MTRs) and PPAP/FAI reports provided.

Prototyping: 1–50 pieces (CNC/3D printing).

Bulk Orders: 500+ pieces (discounts over 1,000 units).

Production: 2–4 weeks for prototypes; 4–8 weeks for bulk orders.

Shipping: 5–7 days (DHL/FedEx air) to Americas/Europe; 2–4 weeks (sea freight).

Yes, for standard parts (customer pays shipping). Custom samples require a nominal fee.

100% refund or rework at no cost if defects are due to manufacturing.

T/T, LC, PayPal (for samples), and 30% deposit + 70% before shipment.

Shipping: FOB/CIF/DDP terms; we handle export documentation and hazardous material certification.

Customs: Door-to-door service includes duty/tax calculations for seamless delivery.

Yes, 5-axis CNC (±0.005mm) and Swiss machining for micro-parts (Ø0.5mm+).

NDA signing and encrypted file transfers; no third-party outsourcing.

Explore More Materials Offered by HDC

Browse HDC's extensive selection of specialized materials, designed to meet diverse industrial needs.

Get an Instant Quote!

Get a quick quote for your project with just a click! Request an instant quote now!

Contact With Us

for any inquiry

40+ Material Options

40+ Material Options