- Home

- Capabilities

- CNC Machining Services

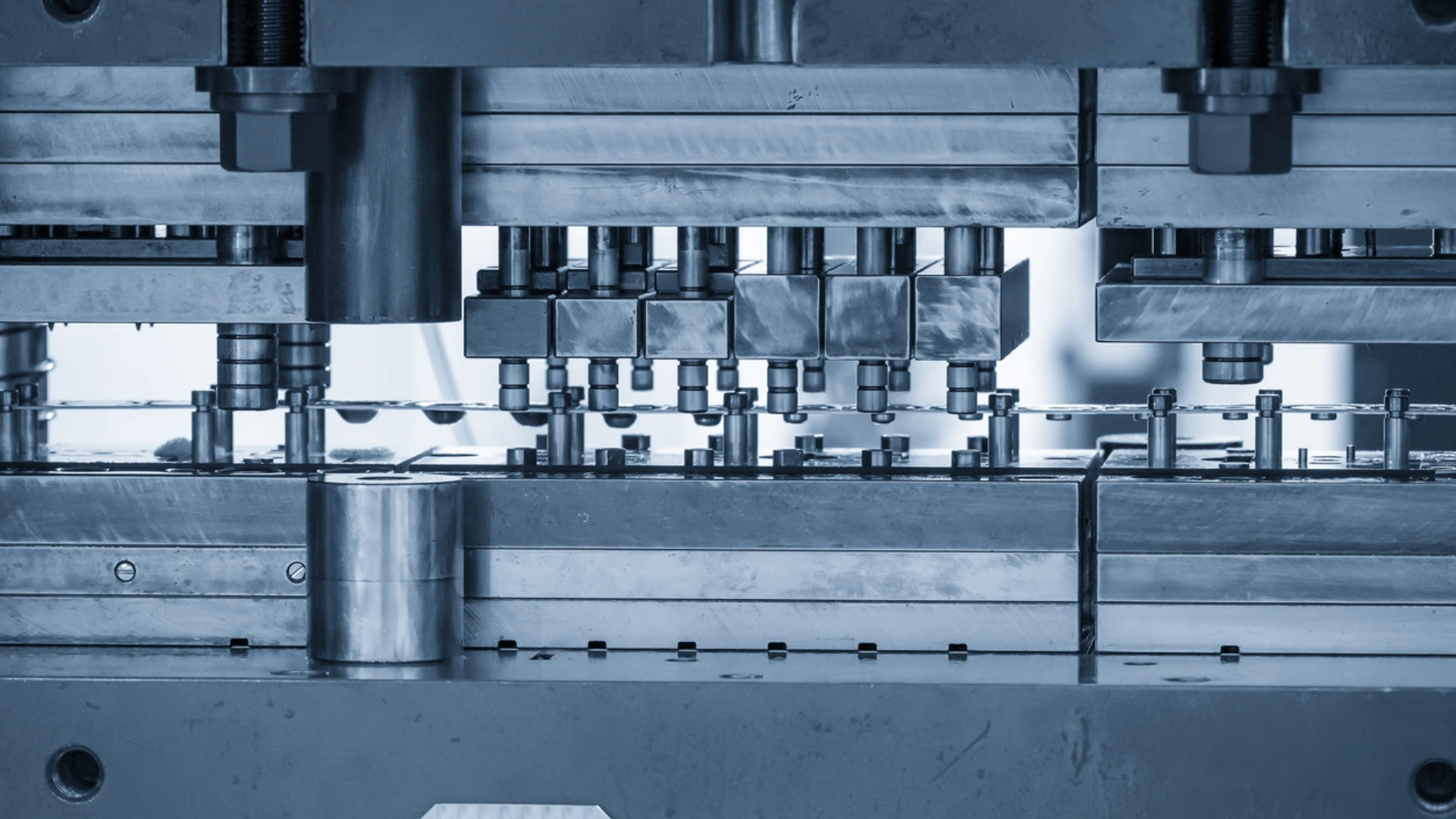

Your CNC Machining Partner for Mission-Critical Components

HDC's 5-axis CNC machining centers deliver ±0.01mm tolerances for aluminum, titanium, and engineering-grade plastics. As a China-based CNC machine shop with 15+ years of aerospace-grade manufacturing expertise, we provide:

• 24-hour Quoting for prototypes & production runs

• 30% Faster Lead Times vs. industry standards

• DFM Analysis included in every custom CNC project

5 Strategic Advantages of Precision CNC Manufacturing

Accelerate Production Timelines While Maintaining ±0.02mm Tolerance Standards.

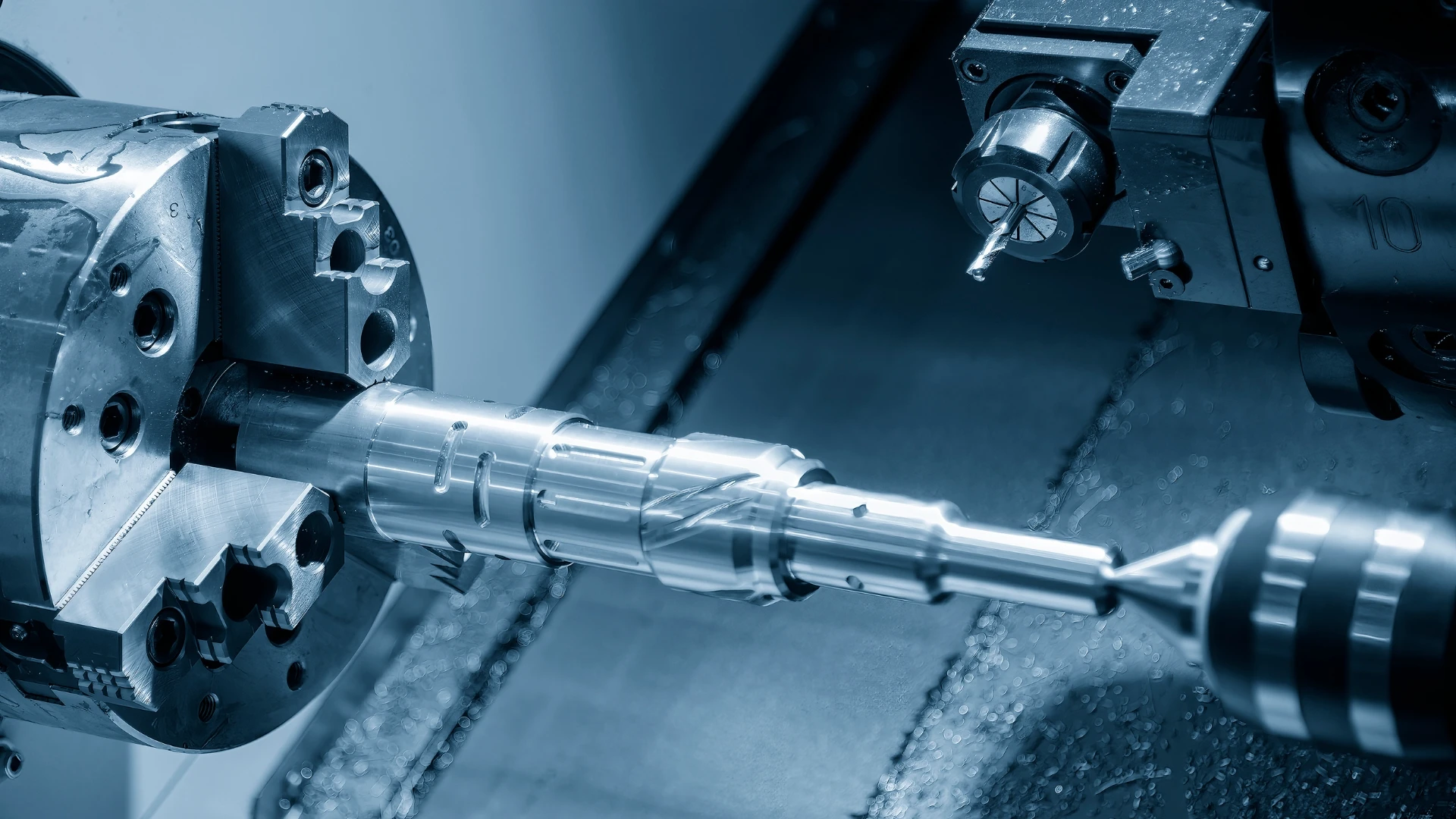

Unmatched Precision & Repeatability

• Achieves ±0.005″ (0.127mm) tolerance consistently

• 5-axis CNC machining enables complex 3D contours

Digital Manufacturing Continuity

• CAM software integration optimizes tooling strategies

• Enables mass customization without retooling costs

Scalable Production Economics

• Zero mold fees for low-volume CNC machining projects

• Per-unit cost decreases by 18-25% at 100+ units

Material Versatility

• Processes 40+ metals (aluminum/steel/brass) & engineering plastics

• Handles exotic alloys requiring specialized toolpaths

Surface Finish Excellence

• Achieves Ra 0.4μm roughness via adaptive toolpathing

• Minimizes post-processing for optical/microfluidic parts

Multi-Technology Synergy

Combines with EDM for hardened steel tooling

• CNC turning + milling hybrid solutions

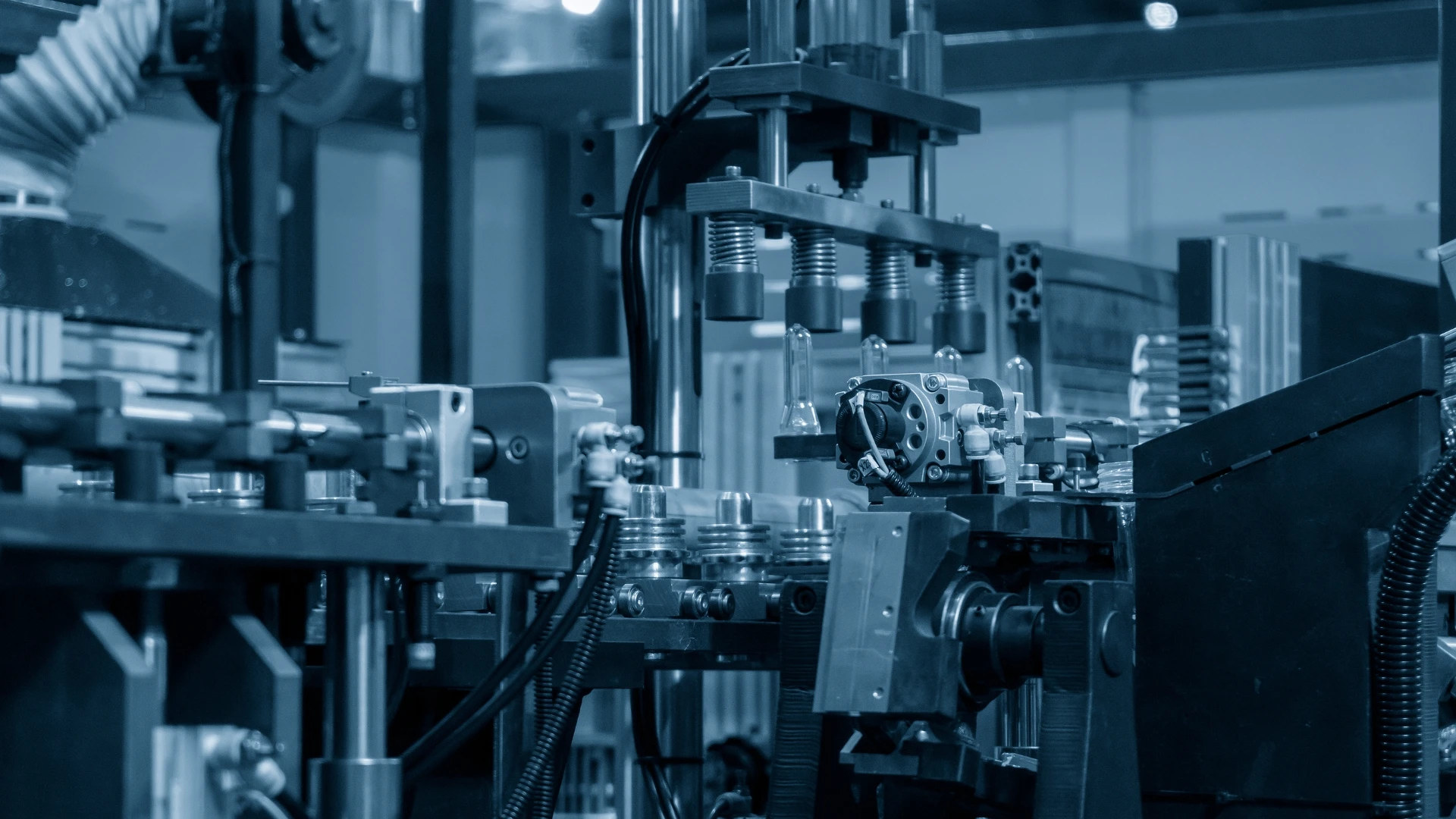

Why Choose HDC Custom CNC Machining Service

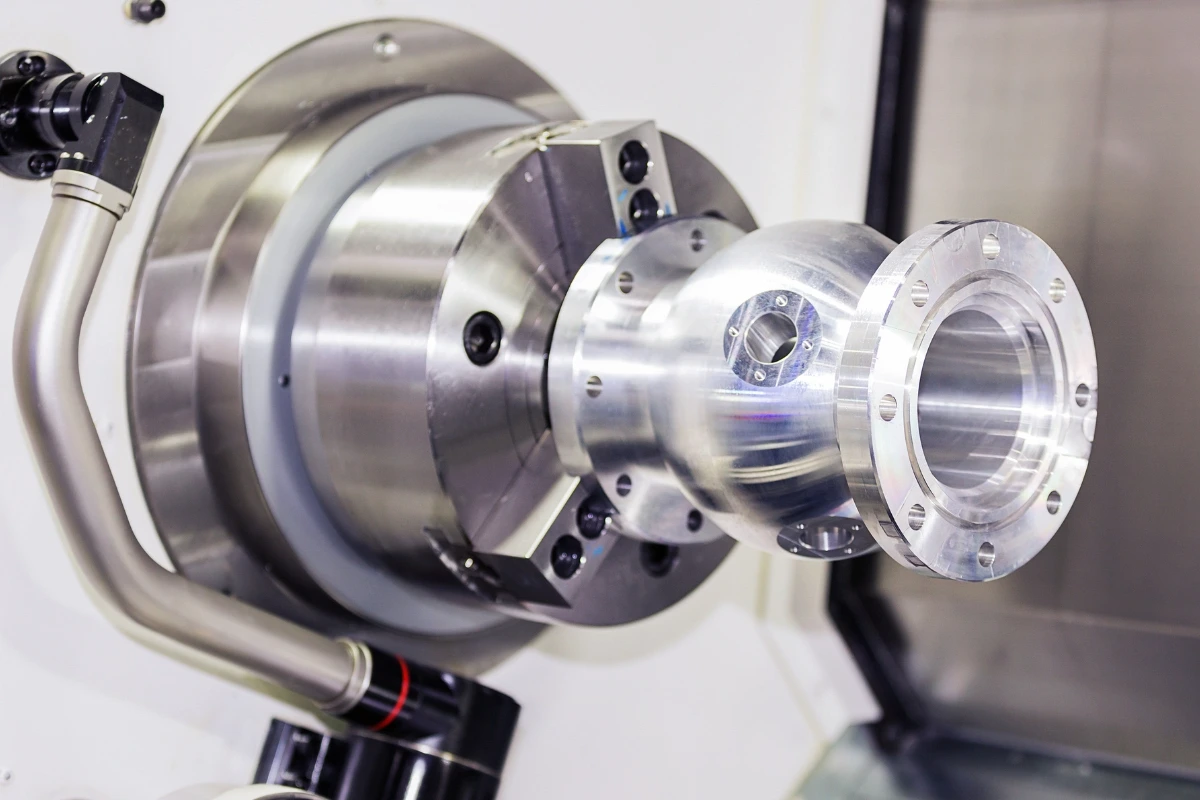

Advanced 5-Axis Equipment

🔹State-of-the-art 5-axis CNC machining centers

🔹Handles prototypes and large-scale production

Consistent Accuracy

🔹Tight tolerances at any production volume

🔹High-precision results for all parts

Diverse Material Options

🔹Supports plastic, stainless steel, aluminum, titanium, and more

🔹Tailored solutions for unique project requirements

Expert Engineering Support

🔹Skilled design and operations team

🔹Optimized designs for enhanced performance and aesthetics

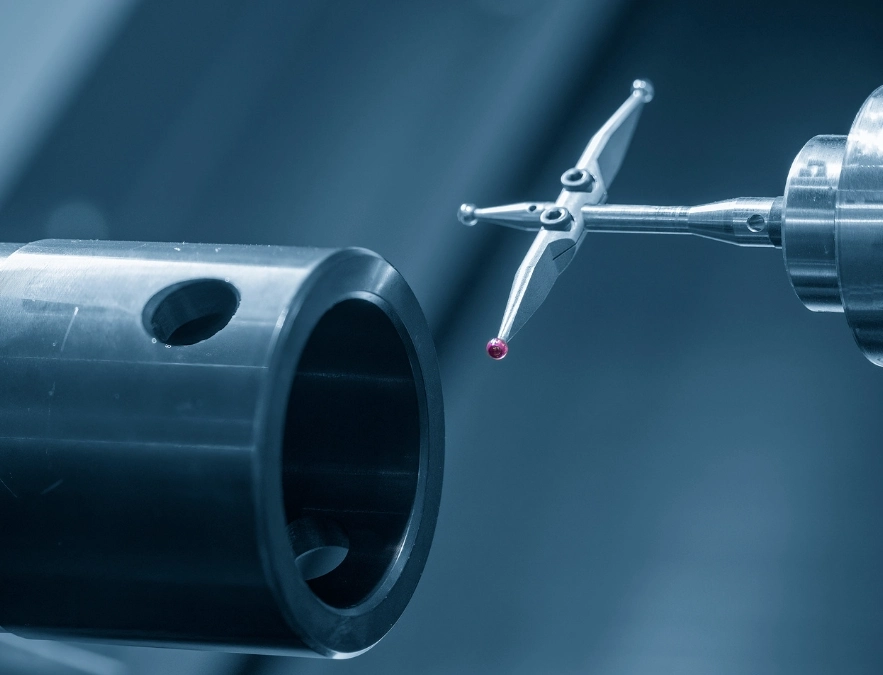

Rigorous Quality Control

🔹Advanced inspection tools (CMMs)

🔹Strict checks at each manufacturing stage

Responsive Customer Service

🔹Multi-language support

🔹FOB or door-to-door delivery

🔹Multiple payment methods

Material Options for Custom CNC Machining Parts at HDC

Explore the diverse range of materials HDC offers for CNC machining, including stainless steel, aluminum alloys, and more, tailored to meet your project's specific needs.

Stainless Steel

Grades Available: 304, 316, 201, 430, etc.

Key Advantages: Highly durable, corrosion-resistant, easy to sterilize

Ideal For: Medical instruments, food processing equipment, demanding environments

Aluminum Alloy

Grades Available: 6061, 7075, 5052, etc.

Key Advantages: Lightweight, strong, easy to machine, good thermal properties

Ideal For: Automotive and aerospace parts where reduced weight is critical

Carbon Steel

Grades Available: 1018, 1045, 4140, etc.

Key Advantages: Superior strength and toughness

Ideal For: General machinery, automotive parts requiring high durability and impact resistance

Polymeric Material

Grades Available: ABS, Nylon, POM, PC, etc.

Key Advantages: Lightweight, versatile, options for enhanced heat resistance or strength

Ideal For: Consumer electronics, automotive components with complex shapes

Titanium Alloy

Grades Available: Grade 2, Grade 5 (Ti-6Al-4V), etc.

Key Advantages: Exceptional strength-to-weight ratio, extreme corrosion resistance

Ideal For: Aerospace, medical devices, high-performance engineering applications

Copper Alloy

Grades Available: Brass, Bronze, and other copper-based alloys

Key Advantages: Excellent electrical conductivity, natural antibacterial properties

Ideal For: Electrical components, plumbing fittings, decorative elements

The Evolution and Impact of CNC Machining

Explore the transformative role of CNC machining in modern manufacturing, highlighting its precision capabilities, industry applications, and future advancements driven by AI and IoT.

CNC machining’s roots trace back to the 1940s and 1950s, when punched tape systems were first used to enhance production speed and precision—particularly for aircraft parts during WWII. This innovation laid the groundwork for modern CNC machine shops, transforming how components were fabricated.

By the 1960s, the adoption of computers and the rise of CAD/CAM software enabled more complex operations. These advancements paved the way for CNC milling, CNC turning, and specialized CNC machining centers capable of tighter tolerances and faster output—further boosting manufacturing efficiency.

Modern CNC systems are prized for their accuracy and versatility, serving industries from automotive and aerospace to medical technology.

Whether it’s metal CNC machining for aluminum, titanium, or other materials, the ability to achieve intricate geometries and consistent quality is a defining advantage.

Despite its benefits, CNC machining demands substantial initial investment and skilled operators trained in advanced software and hardware. Balancing CNC machining cost with high-quality output remains crucial for businesses pursuing custom CNC machining or large-scale CNC manufacturing projects.

Looking ahead, the integration of AI and IoT will bring smarter, more adaptive processes, improving accuracy, reducing lead times, and supporting real-time monitoring. Innovations like 5-axis CNC machining continue to push performance boundaries, suggesting an exciting era of further automation and efficiency gains—making CNC machining indispensable in tomorrow’s manufacturing landscape.

CNC Machining Across Industries

Discover how CNC machining is integral to different sectors by producing precise and custom components essential for aerospace, automotive, medical, electronics, and defense industries.

Automotive Industry

Key Components:

🔹Engine blocks & transmission housings

🔹Custom suspension parts

🔹EV battery enclosures

Advantages:

🔹 0.1mm precision for perfect part fitment

🔹 Cost-saving bulk pricing for 500+ orders

Aerospace Industry

Key Components:

🔹Aircraft structural brackets

🔹Landing gear components

Advantages:

🔹 Specialize in lightweight aluminum & titanium

🔹Strict quality tracking for every batch

Medical Industry

Key Components:

🔹Surgical instrument handles

🔹MRI machine components

🔹Implant prototypes

Advantages:

🔹Medical-grade stainless steel machining

Electronics Industry

Key Components:

🔹Heat sink assemblies

🔹Sensor housings

🔹Micro connector parts

Advantages:

🔹Precision down to 0.05mm tolerance

Defence Industry

Key Components:

🔹Vehicle components

🔹Communication device chassis

Advantages:

🔹Secure project handling protocols

🔹Ballistic-grade material experience

Precision Capabilities of CNC Machining

Explore the remarkable precision levels achievable with CNC machining, highlighting its capacity to meet stringent tolerance requirements across various applications.

| Feature | Tolerance Range | Industry Example |

|---|---|---|

| General Dimensions | ±0.005 inches (±0.127 mm) | General Manufacturing |

| Fine Detailing | ±0.001 inches (±0.025 mm) | Aerospace & Medical Devices |

| Surface Finish | As low as 8 microinches (0.2 micrometers) | Optics & High-end Electronics |

| Hole Diameter | ±0.0005 inches (±0.0127 mm) | Precision Engineering |

| Positional Accuracy | ±0.0001 inches (±0.00254 mm) | Automotive & Defense |

FAQ

Find answers to common questions about our CNC machining services, helping you understand the process, materials, and options available for your custom projects.

HDC offers a wide range of materials for CNC machining, including stainless steel, aluminum alloys, titanium, carbon steel, copper alloys, and various polymers. Each material is chosen for its properties to meet the specific requirements of your project.

We accept most CAD file formats, including DXF, DWG, STEP, and IGES. Providing a clear and detailed design file will help ensure the accuracy and efficiency of the manufacturing process.

Yes, HDC is equipped to handle all sizes of production runs, from single prototypes to large-scale production batches. Our facilities can adapt to your project's volume needs with the same level of precision and efficiency.

Lead times can vary based on the complexity and volume of the project. Typically, we can turn around prototypes in 4-6 weeks, while larger production runs might take 2-4 months. We always work to meet your deadline and can provide more specific timelines once we review your project details.

HDC maintains strict quality control standards throughout the CNC machining process. We use advanced measurement and inspection techniques, including CMM (Coordinate Measuring Machines) and visual inspections, to ensure every part meets your specifications and our high-quality standards.

Absolutely! Our experienced engineers are available to assist with part design and can provide input on manufacturability, material selection, and cost-efficiency to optimize your product for CNC machining.

Get an Instant Quote!

Get a quick quote for your project with just a click! Request an instant quote now!

Contact With Us

for any inquiry

Other Service HDC Provide

Explore the range of additional services HDC offers, from custom design and prototyping to logistics and post-manufacturing support.