Custom Medical Machining: Precision Manufacturing for Healthcare

This article discusses the various types of machinery and components involved, common materials used such as stainless steel and titanium, and the key advantages and challenges of this process. Discover how custom medical machining contributes to the medical, pharmaceutical, and electronic medical equipment industries by delivering customized solutions that meet stringent requirements.

Understanding What Custom Medical Machining Is

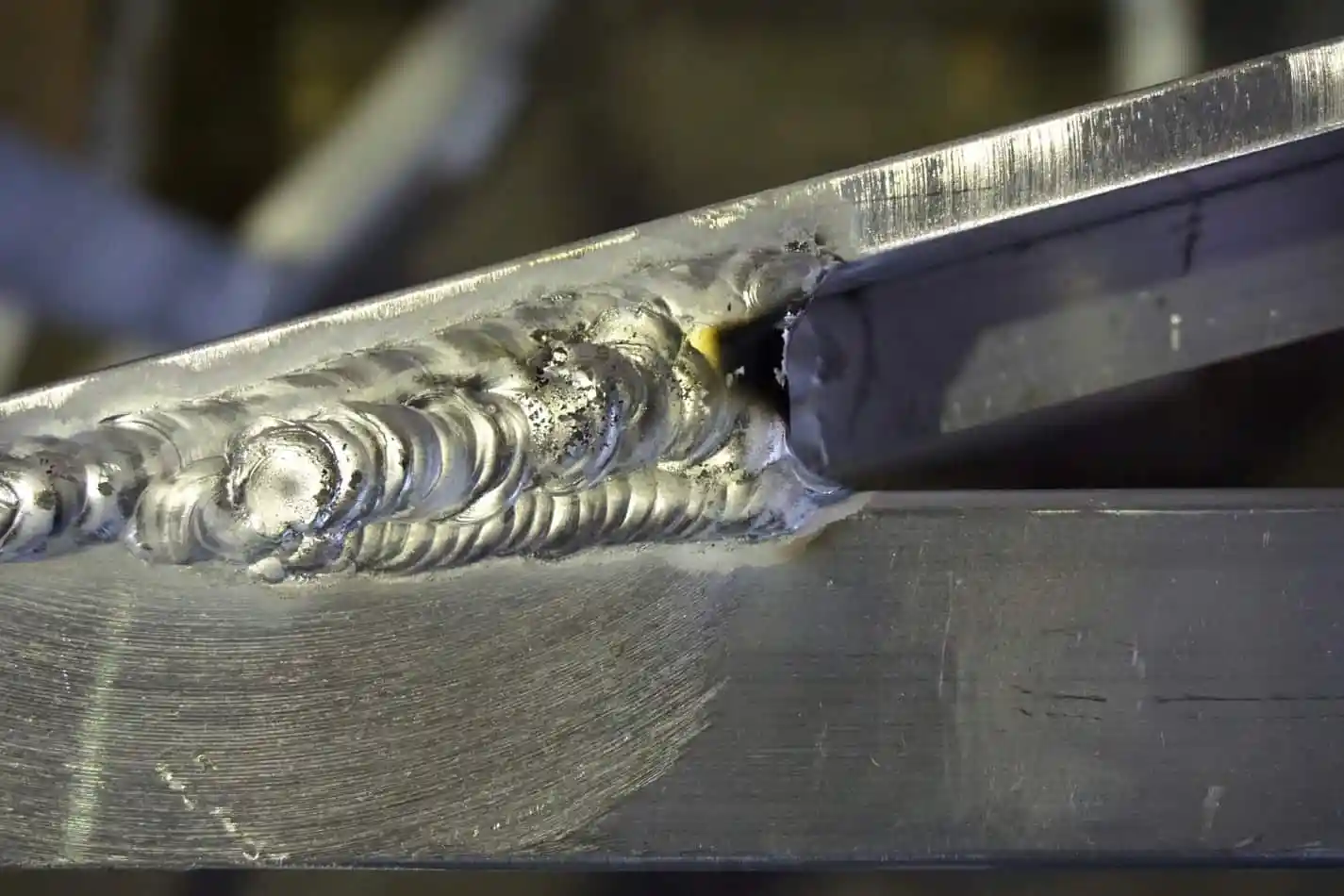

Custom medical machining is a manufacturing procedure that is done to produce parts and components of medical, medicinal, and even pharmaceutical equipment. It’s easily understandable with its term – it is the production of highly specialized and customized parts and components (typically using CNC or computer numerically controlled machines).

This process is smiled upon by a lot of businesses and companies because of how flexible and versatile it is. Tested and proven, custom medical machining was able to produce the hardest, most challenging, and most complex of parts.

Examples of Medical Machining

When it comes to custom medical machining, the range of machinery and equipment that are catered by its parts and components is vast. I’m talking about everything from standard machines used in hospitals and clinics to complex and high-tech machines and advancements, too.

To name a few of the most common and most accustomed medical and medicinal machines, they include:

When it comes to custom medical machining, the range of machinery and equipment that are catered by its parts and components is vast. I’m talking about everything from standard machines used in hospitals and clinics to complex and high-tech machines and advancements, too.

To name a few of the most common and most accustomed medical and medicinal machines, they include:

- MRI Machines

- PET and CT Scanners

- X-Ray Machines

- Ultrasound Machines

- Sterilizers

- Surgical Handheld Machines

- And Many More!

What Custom Medical Machining Components Are Commonly Made?

As mentioned above, the library of selection of custom medical machines is not that narrow. This means, the most common components and parts that are commonly made via CNC medical machining are significant, too.

Three (3) of the most common applications and components produced and manufactured via custom medical machining are:

Medical Implants

These include body implants, replacements, and other implants that often require accurate and precise measurements in order to be valid. Typically, these components need to have a tolerance of ±4 μm.

Medical Instruments

In addition to medical implants, medical instruments heed the effectiveness and efficiency of custom medical machining, too. We’re talking about biopsy spacers, clinical tubes, blades, surgical tools, and other types of instruments that are crucial in the medical and surgical world.

Electronic Medical Equipment

Finally, most medical and pharmaceutical equipment and machinery wouldn’t be complete without some of its parts. These parts often make up the entirety of custom medical machining. Like the machines and equipment we outlined above, such as sterilizers, defibrillators, PET and CT scanners, MRI machines, and so on!

Types of Materials Used For Custom Medical Machining

Therefore, the raw materials and products used for custom medical machining are only a few select products – typically those that have been tested and proven in the field already.

Some of the common materials used for the manufacturing of custom medical machining parts and components include:

Therefore, the raw materials and products used for custom medical machining are only a few select products – typically those that have been tested and proven in the field already.

Some of the common materials used for the manufacturing of custom medical machining parts and components include:

- Stainless Steel

- Titanium (And Its Alloys)

- Polymers and Composites

Advantages of Custom Medical Machining

- All parts and components will be manufactured precisely and accurately

- There will be little-to-no chances of defects and needs to re-modify

- The design you want can be custom-made according to your needs

- Production time and lead time will be explicitly faster and more urgent

- You can be sure that the quality of the parts and components will be high

Disadvantages of Custom Medical Machining

- Because of their versatility, some of the designs could not be ready and prepared for production

- They are usually costlier and more expensive than standard or traditionally-manufactured parts and components

- Modification in the middle of production is not possible because it will be run by the CNC machine from start to finish

Are Chinese Custom Medical Machining Manufacturers Reliable?

Yes, in fact, in the global market, Chinese manufacturing companies are the leading and most reliable when it comes to custom medical machining. The skill, experience, resources, and manpower that they have outruns all other countries and nations.

Why You Should Choose HDC Manufacturing For Your Custom Medical Machining

HDC Manufacturing is an expert when it comes to custom medical machining – and we have been for 12+ years! Our expertise and overall capability of manufacturing custom medical machining parts and components have been viewed by many businesses and corporations as a positive.

Whether you need CNC medical parts made of aluminum, stainless steel, titanium, and even plastic, you can bank and rely on us here at HDC Manufacturing to produce and create them for you!

Other than custom medical machining, as a company, we are also revered as experts and professionals when it comes to other services and capabilities. You can also place your complete trust in us if you need CNC rapid prototyping, laser cutting services, aluminum forging, sheet metal fabrication services, and many more!

Join hundreds to thousands of manufacturing companies and suppliers in getting the best and highest quality of custom medical machining parts without beating a buck!

Conclusion

Medical grade custom machining is a critical component in the field of medical manufacturing, where bespoke-designed parts and elements are essential for the proper functioning of medical equipment. Precision and flexibility of the production process are aimed at the production of the high-quality and specialized items like implants and electronic medical devices. It does give an advantage of accuracy and speed but there are issues like costs and design limitations too. Notably, despite the fact that HDC Manufacturing is one of the most reliable manufacturers that has accumulated years of experience, businesses are assured of the exceptional custom medical machining services that they deliver as well as a wide range of other manufacturing capabilities, to fulfill the peculiar needs of the medical industry.