Can you powder coat aluminum? The answer is YES! Perhaps you are unsure whether your aluminum parts can be powder-coated or if powder coating is suitable for your aluminum products. This article will answer your questions from the perspective of a custom metal fabrication shop.

What is powder coating?

Powder coating is a dry surface treatment for metals, including aluminum.

It uses a specialized spray gun to apply finely ground dry powder(made from resins such as epoxy and polyester) onto the surface of metal parts.

After high-temperature baking(typically 160℃-200℃), the plastic powder will melt, level out, and cure, ultimately forming a coating that is strong, smooth, and aesthetically pleasing.

Why can aluminum be powder coated?

- The good conductivity of aluminum ensures that it adheres evenly to aluminum parts through electrostatic adsorption when powder coating.

- Aluminum’s excellent heat resistance (melting point of 662°C) ensures that the workpiece will not deform during the baking process of powder coating.

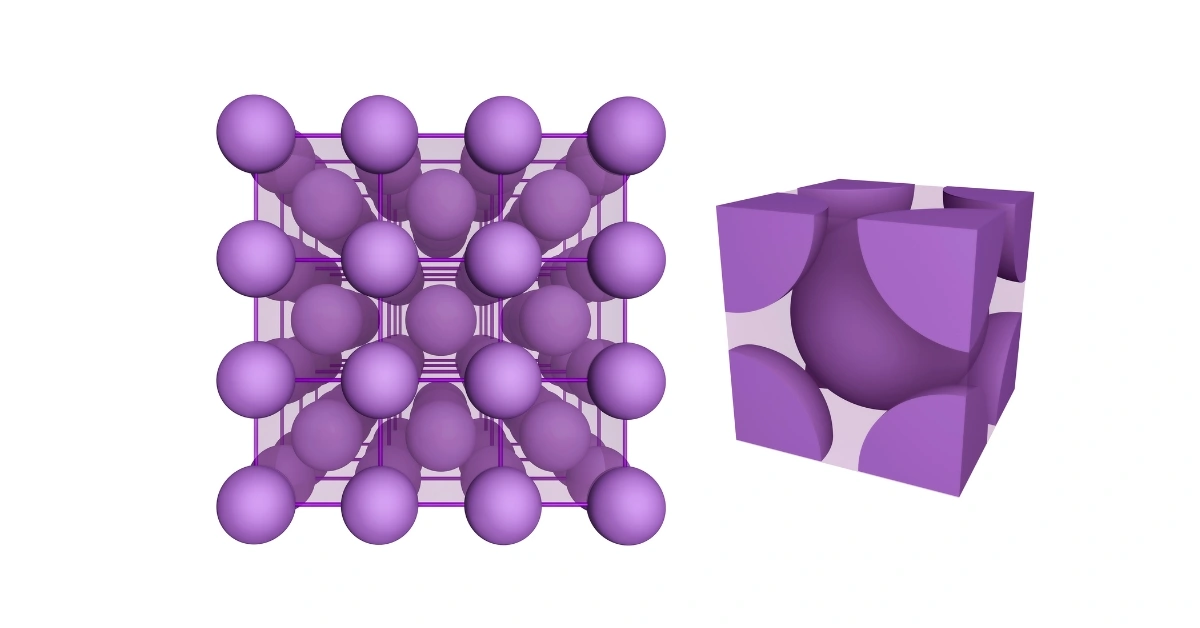

- Aluminum has a natural oxide film (Al₂O₃) on the surface, which has a certain roughness that helps powder coating adhere. After chemical treatment or sandblasting, an artificial conversion film is formed, which can further enhance the adhesion of powder coating to aluminum.

Types of Powder Used in Aluminum Powder Coating

Thermosetting Plastic Powders

Thermosetting plastic is the most used material for powder coating, and the common types used for aluminum parts are: Epoxy, Polyester, and PU. During baking, it melts and cures, forming a permanent coating on aluminum through a chemical process called crosslinking. This coating is hard, has overall better wear and chemical resistance than thermoplastic powder.

Thermoplastic Powders

Unlike thermosetting plastic, thermoplastic(PE, PVC) only changes physically during powder coating, so the process is reversible. The resulting coating is softer and mainly used in specific functional applications, such as a protection layer for aluminum bushings, tubes, and wire.

How to powder coat aluminum?

Pre-processing

Cleaning

Before powder coating, it is necessary to use alkaline or neutral degreasers to thoroughly clean the aluminum surface to remove grease, dust, or oil stains that may affect adhesion.

Sandblasting

Sandblasting enhances the roughness of aluminum surfaces mechanically, thereby improving the adhesion of powder coatings.

Pickling

Pickling is a chemical process that removes the oxide layer on the aluminum part, activates and slightly corrodes the surface to form a rough microstructure, which improves the bonding between the powder and the aluminum substrate.

Conversion coating treatment

Place the aluminum part into a chemical conversion solution containing chromium, zirconium, or titanium, allowing a non-metallic, porous chemical conversion film to form on its surface.

This not only enhances the adhesion of powder coatings but also provides corrosion protection for the aluminum substrate.

Washing and drying

After being treated with chemical agents, aluminum parts need to be rinsed first with clean water to remove surface residues, and then thoroughly rinsed with deionized water (DI Water) to eliminate water spots and mineral stains.

After washing, dry or blow away the remaining moisture to keep the surface of the workpiece dry.

Spraying

Evenly spray the negatively charged powder onto the positively charged aluminum surface by using a corona or friction spray gun.

The composition and color of the coating powder can be selected based on your design, and the coating thickness should be kept within 60-120 microns.

Baking and curing

The aluminum parts adsorbed with powder are placed in a curing oven and heated to 160℃-200℃, and the heating time is controlled within 10-20 minutes.

During this process, the powder melts, levels out and finally solidifies into a smooth, sturdy solid coating.

Cooling

Remove the aluminum parts from the curing oven and let them cool naturally; this step ensures that the coating is firmly attached to the aluminum parts.

Inspection

After completing all the above steps, the powder-coated aluminum parts need to be inspected to prevent uneven coating surface, bubbles or peeling.

Advantages of aluminum powder coating

Corrosion resistance

Compared to traditional coatings, powder coatings are thicker and can delay corrosion and oxidation on their surface.

Color diversity

Aluminum powder coating allows you to flexibly choose a variety of colors or finishes(like metallic or textured) to spray on the surface of aluminum parts, which provides more options for customized product design.

Durability

Powder-coated aluminum has sturdy surface protection that resists wear, scratches, or rust, extending the life of the aluminum product and making it ideal for harsh outdoor environments.

Environmentally friendly

Unlike traditional liquid coatings, powder coatings contain no organic solvents (VOCs) and emit virtually no harmful gases. As an environmentally friendly process, powder coatings generate minimal waste, and the oversprayed powder can be recycled and reused.

Cost effective

Plastic powder used for aluminum powder coating is easily available and can be sprayed in one go to achieve the customized thickness, eliminating the cost of multiple spraying and drying. Recyclable powder also reduces production costs.

Disadvantages of aluminum powder coating

- If the coating is thicker, the details of the aluminum workpiece with fine texture cannot be clearly displayed, which will affect the desired effect of the design.

- When the coating is partially damaged, spot spray repairs will leave obvious marks, so all the coating needs to be ground off and re-sprayed, which is time-consuming and costly.

- Changing the color of powder coating is more complicated than changing the color of traditional paint, so it is more suitable for large quantities of aluminum parts. If it is a small batch order, it will affect production efficiency.

Application of aluminum powder coating

Vehicle parts

Powder coating meets the wear and corrosion resistance requirements of vehicle parts, most notably auto wheels and motorcycle frames.

Architectural components

Powder coating enhances the scratch resistance and aesthetics of aluminum architectural components such as handrails, curtain walls, and patio furniture.

Electrical application

Computer housings, lighting fixtures, and other application parts made of aluminum also benefit from powder coating. It enhances the heat resistance and cleanability of these components.

Industrial machinery

Powder coating offers excellent durability and chemical resistance, making it effective in protecting critical components of machinery in harsh industrial environments.

Comparing Powder Coating to Other Finishes

Powder coating vs anodizing

Compared to anodizing, powder coating allows for more colors and surface finishes. Additionally, for large quantities and complex parts, powder coating is more cost-effective.

Powder coating vs liquid painting

Traditional liquid paint pollutes the environment after evaporation and has a low utilization rate. Compared with it, powder coating is not only environmentally friendly but also efficient and durable.

Conclusion

Aluminum powder coating is an affordable, efficient, and durable option for brand manufacturers who design products requiring a personalized surface treatment.

HDC offers custom aluminum metal processing services, including sheet metal, CNC-machined parts, forged parts, and castings. We offer one-stop processing and powder coating services. If you require a quote or technical support, please contact us, and we will provide timely service.

Discover more with our blog posts.

Recent Posts

Discover more about our products

HDC Products

Instant Quote!