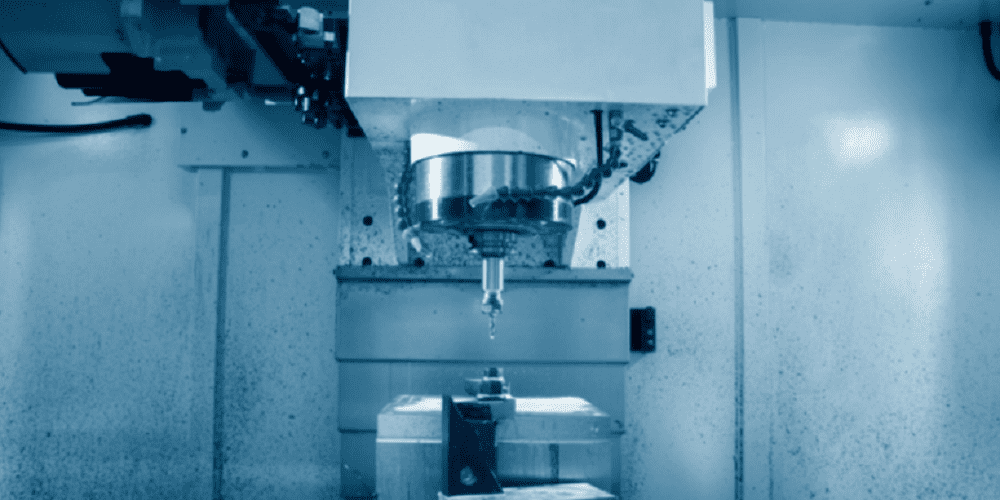

Titanium Machining Services

An OEM & ODM company like HDC will always give you the remarkable titanium machined parts you would ever imagine. Titanium parts require a masterful maker like HDC that assures the finest results when manufacturing titanium.

HDC’s titanium has an impressive temperature resistance, whether it be high or low. Our machines are designed to produce undoubtedly perfect non-harmful titanium parts. You can choose from our surfaces to put on your components.

Technicians and workers of HDC are giving their 100 percent in every project we encounter. Our whole team unites as one to deliver inexpensively dependable titanium parts. In every machining process, we are making it with high professionalism and expertise.

HDC is very strict when it comes to quality control. In doing all kinds of machining using titanium material, we manufacture with care and thorough inspections. HDC titanium machining services accept every industry that needs our help.

When customizing your material, you’re not only choosing its grade and customize the idea. You’re also welcome to choose your preferred shipping and payment method, as well as the trade terms.

When choosing the right manufacturer, I’m sure that you will consider everything that was said above. HDC is always here to serve your CNC machining needs, also sheet metal fabrication service, metal stamping service, pressure die casting, aluminum forging, aluminum extrusion, blow molding for plastic parts, and so much more to choose from!

Looking for the best titanium machining services supplier? Come on now with HDC!

Titanium Machining Services | The Ultimate FAQ

Introduction

Titanium – the word came from the Greek word “Titans” which basically means the Gods. The strong material has the atomic number 22 in the periodic table and has an atomic weight of 47.87. The metal is now one of the most popular metals used in modern era industry-shaping with high durability, ductility and strength. Technically it is now ruling most of the metal industries along with stainless steel and aluminum.

1. What Is Titanium, And Why Is It A Popular Material?

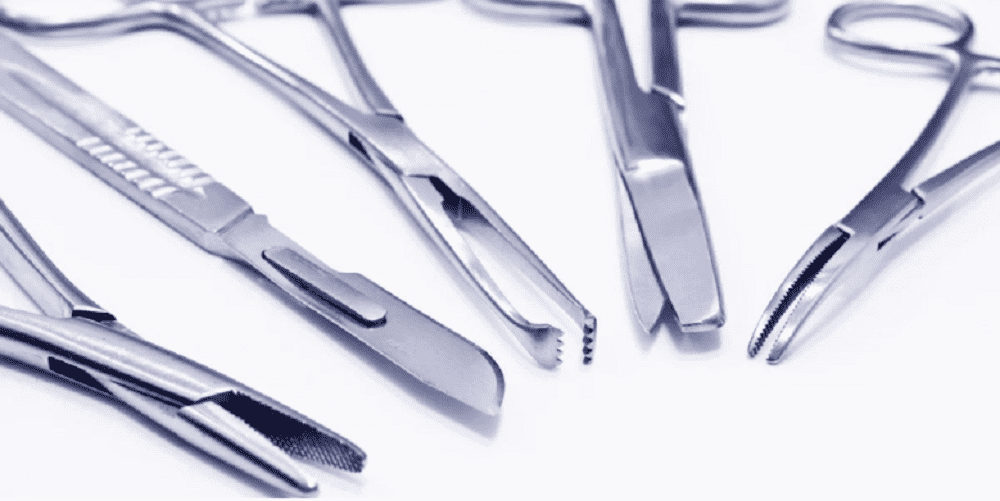

Titanium is a very lightweight and highly durable metal that can be used to build many parts from many industries. From watches, earrings to aerospace parts, surgical and military equipment – titanium are being used everywhere nowadays.

The name came from the Greek word for Gods, “Titan”. So, we can understand the strength and durability behind this marvelous material. For the following reasons, titanium is a very popular material and being more and more popular day by day –

- As we have stated, you can find the material very strong but lightweight to work with. Compared to steel, a titanium bar is 40-45% lightweight.

- Parts made from titanium are rust and corrosion-resistant.

- Titanium can be easily alloyed with iron, molybdenum, or aluminum which makes it perfect for a vast range of industries.

- For lightweight, it has aerospace applications while for salt resistance, Titanium also has many underwater and marine applications.

Nowadays, it is one of the most popular metals in the market.

2. Why Use Titanium Machining Services?

For many reasons, you can use titanium machining Services. It is a very good metal to work with because of –

- Its high strength and durability but low density. For these reasons, it’s best to put in those parts where you need low weight but good strength.

- Lightweight and resistant to temperature makes it perfect for aerospace industries.

- For corrosion resistance and salt resistance, you can certainly use it in ships and boats which gives it underwater and marine applications.

- Last but not the least, even in watch industries, they are praised and appreciated for being lightweight on the wrists.

Moreover, as they can be alloyed easily with many other metals, machining them becomes quite easy.

3. What Are The Most Common Types Of Titanium Alloys?

Titanium alloys are very strong, durable, and lightweight. You can work with them very easily. The alloys can be categorized as Alpha, near-Alpha, Beta, and near-Beta alloys.

Grade 1-4 alloys are non-alloyed titanium that is low in strength but has high corrosion.

Among all the alloys, Grade 5 titanium Ti 6Al-4V is very popular to work with. Minimum 50% of the world’s titanium is used in this form. This is actually an Alpha-Beta alloy that has 6% aluminum, 4% vanadium, 0.25% iron, 0.2% oxygen in it. Most of aerospace fasteners, structures, and turbines are made of this alloy. Besides, engine parts, sports and marine equipment parts are also made with this alloy.

Ti 5Al-2.5Sn (Grade 6) is another alloy known for its applications in aerospace parts. It is a non-heat treatable alloy with much popularity to work with because of its durability, strength, and temperature tolerance.

Another alloy has versatile usage in different industries like aerospace, marine, and medical sectors. It is Ti Grade 9 (Titanium 3-2.5). Besides Titanium, it has 3% Aluminum and 2.5% Vanadium.

In the medical sector, the most used Titanium alloy is Ti 6AL-4V ELI (Grade 23). This can be easily molded and has good performance in bone and joint fixation surgeries.

Other popular alloys are Titanium Beta 21S, Ti 3Al 2.5 (Grade 12), and Titanium 15-3-3-3.

3. What Things To Consider In Titanium Machining Services?

Titanium CNC Machining is a popular process for manufacturing many parts from numerous industries like Medical, Automotive, Marine and Aerospace. Whatever your part is and whichever industry it is a part of, you must consider the following points while doing CNC machining with Titanium –

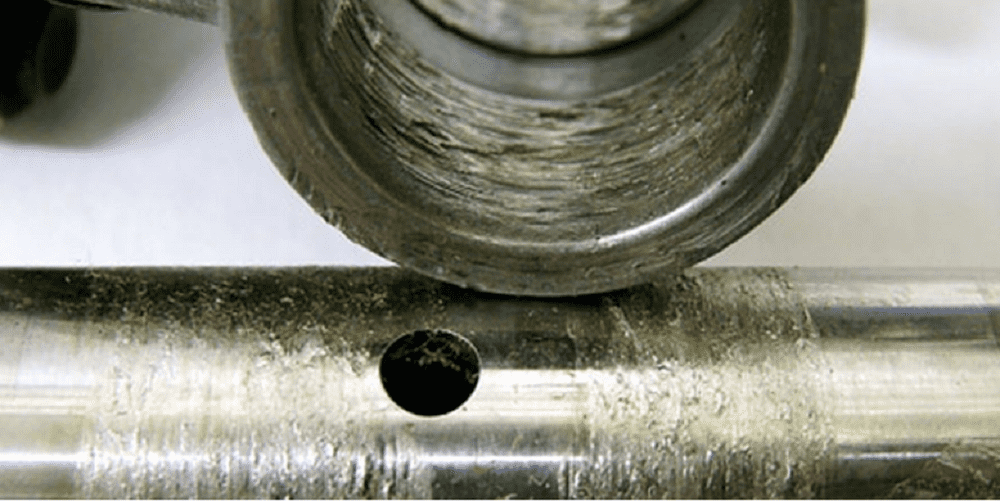

- There are possibilities of adhesive wear or galling if two parts of Titanium are cold-welded. The machining should be in such a way that seizing up can be avoided of two contact points of the metal.

- You should consider reducing RPM in a CNC machine while working with Titanium. Besides, you can also use a cooling machine as Titanium produces much heat at the contact points while CNC machining.

- As Titanium is rather less flexible compared to other metals and their alloys, you should provide a hard grip on the CNC machine while working with this metal. The automation should be kept running while working on a big scale for maximum benefits.

- The CNC machine parts should be stronger and durable compared to Titanium. Otherwise, it may lead to broken parts.

- The tools should be as sharp as they can be because of the strong nature of this material. Besides, adding a secondary finishing stage can also help you give good polished results.

4. Why Is Titanium Difficult To Machine?

Many reasons make Titanium a little difficult to work with –

- The formation of Titanium requires much more strength than other materials

- Because of surface oxidation and lower thermal conductivity, the tools cutting the material can lose their edge quite easily

- The swarf of Titanium are flammable and can create problem in case of a fire in the working place

- It has a 40-50% lower elasticity modulus than that of steel and its alloys which can increase uncomfortability to work with it

- Automation is very difficult if you are not working with the right people. A slight difference in the automation process from the recommended one can lead to the jeopardy of your production

5. How To Achieve High-Speed Titanium Machining?

Because of its properties, Titanium is a good material to work with. But for the same reasons, you may find it difficult to increase the production speed with Titanium machining. But there are certain techniques to increase the speed.

Cutting Tools

Cutting Tools must be chosen according to the properties of Titanium to get the best speed possible. The material used in the cutting tools is the key for high-speed manufacturing. The material in the tool should be –

- Highly resistant to temperature

- They cannot mix with Titanium chemically while the temperature is high

- The strength and durability of the material should be pretty high

- Need good thermal conductivity rate

Turning With Rotary Inserts

This technology has around passing path for the material and cuts the metal without giving it the time to heat up. So, this can be easily used for turning Titanium without having risk of temperature.

Cutting With Ledge Tools

You can use tools that have thin protruding ledges to cut Titanium. Chipping and flanking with these tools can be easy and speedy. The chips are very thin and can be used in many parts’ production. These types of tools were first developed by General Electric.

Ultrasonic Vibration

You can use ultrasonic vibration to remove the extra metal for giving Titanium the shape you desire. If you use ultrasonic vibration to your tools, the process becomes much easier and the force helps to give the cutting tools better longevity.

If you can apply the above-mentioned strategies, then you can surely pace up the speed of titanium machining. Certainly elasticity, temperature and high strength are the three key parts that can meddle with titanium machining. If you can match your tools with these properties, then you can certainly have a high-speed manufacturing process.

6. Which Grade Of Titanium Is Best For Machining?

Various grades of titanium are available in the market. Titanium alloys are good in strength, ductility, and durability.

Grade 1-4 titanium has hardness 100, 90, 80, and 70 giving them machinability 46%, 40%, 35%, and 28%. These are basically the easiest materials to machine.

When it comes to alloys, almost 50% of all titanium used in machining are of Grade 5 Titanium Ti-6Al-4V, 4906, 4920, 4928. This Alpha-Beta alloy has good properties for machining and manufacturing products for different industries like medical, marine, and aerospace.

Ti-3Al-2.5V, 4943, 4944 are also popular for versatile industries. The alloy has 28% machinability and works quite well even in the medical field.

7. How To Find The Best Titanium Machining Services Company?

You can find some tips here to help you with finding out the best titanium machining service provider –

Quality Control

Check out the paper trail and numbering regarding the quality control process of the CNC machining provider to find out if their quality control process is up to the mark.

Experience In Titanium

CNC machining is a modern-day cutting-edge technology. You must learn if a service provider has enough experience in titanium as it has many unusual properties to work with.

Minimum Order Quantity

Check out the MOQ of the company. If it has a lower minimum order quantity for titanium products, then it can help you enter the market easily.

Delivery Schedule

You should find out the delivery time required for an order from the company. If their past records show delivery on time has been achieved, then you can proceed.

Customer Care

Customer care services can be measured through communication and quotation achievements. If you go through it, then you can measure easily if they are going to give you comfort in working or not.

If you are satisfied with these points of different CNC machining companies, then you should analyze the market and proceed to a field visit, then you can absolutely understand which is the best one to work with.

Conclusion

Titanium is a popular material nowadays. The parts manufactured with this strong material are ruling many industries, from medical to vehicles and even ornaments and accessories. For lightweight titanium ornaments and watches are even embraced by everyone around you. These are all the reasons you should go for titanium machining for your next project.

[toc]