Table of Contents

Overview

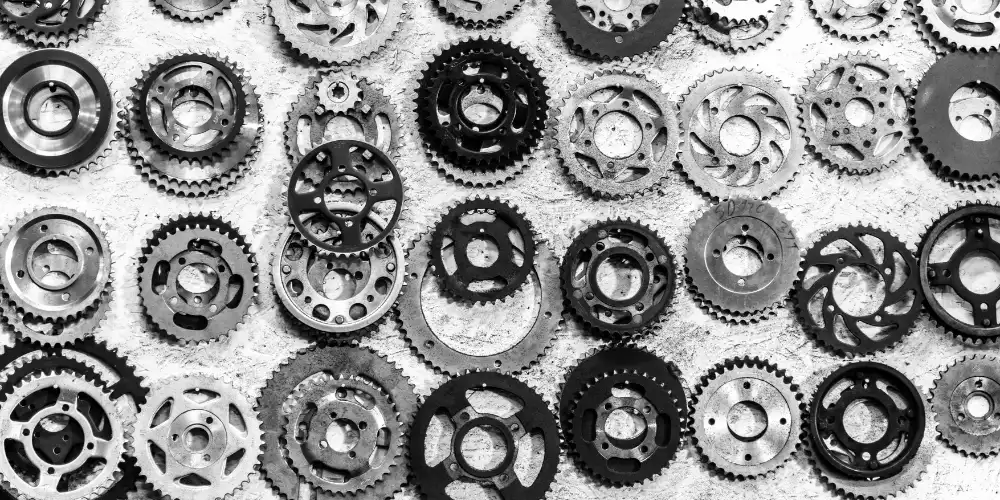

If you’re trying to look for the best and most reliable CNC sprocket manufacturer in the country, then you’re on the right page! We here at HDC Manufacturing have produced numerous CNC sprockets for different types and kinds of machines.

In this blog, we will be discussing everything you need to know about CNC sprockets before purchase so you don’t have to dig deeper into it!

Process of CNC Machine a Sprocket

- Roughing: Using appropriate cutting tools, removes most of the material to form the initial contour of the sprocket.

- Finishing: Using finer cutting tools, accurately cuts sprocket teeth and other features to achieve the desired final size and surface smoothness.

- Drilling: Performs drilling operations on sprockets, if necessary (e.g., for mounting), using drilling tools.

- Chamfering/Deburring: Remove sharp edges and burrs to enhance overall surface smoothness, using appropriate tools or methods.

- Quality Control: Periodically checks dimensions and tolerances of machined sprockets using measuring tools such as calipers, micrometers, and gauges to ensure that final product meets specifications.

- Finishing: Depending on the actual application, surface treatment such as heat treatment, plating or coating may be required to enhance the performance of the sprocket.

- Assembly and Testing: If the sprocket is part of a larger system, assemble it into the system and perform functional tests to ensure proper operation.

CNC Processes Suitable for Machining Motorcycle Sprockets

CNC Processes Suitable for Machining Motorcycle Sprockets

As machining of motorcycle sprockets requires precise action, CNC (Computer Numerical Control) technologies are perfect as these processes have high accuracy and repeatability. The main CNC methods used in the manufacture of sprockets include shaping and tooth profile cutting using milling, forming a central hub along with providing accurate mounting holes using turning, creating a smooth surface finish by means of grinding and developing custom designs through EDM. With the aid of CNC machining, reliable and efficient motorycle performance is ensured by customizing sprockets to meet the requirements.

Common Materials Used for CNC Machining Motorcycle Sprockets

Most motorcycle sprockets are CNC machined in different materials that have specific attributes to be used for particular requirements of performance.

- Steel: Steel is widely used because it has high strength and long life span. It has good wear resistance and is suitable for use under high stress. Steel of different grades may be used, depending on the required strength and hardness requirement.

- Aluminum: The lightweight property is chosen for aluminum and which reduces overall motorcycle weight. It has a good corrosion resistance and is applied in race cars and high-performance motorcycles.

- Stainless Steel: Stainless steel provides both resistance and strength. It is often used especially in sprockets to prevent rust so as its durability from dampness or corrosive interiors.

- Titanium: Titanium is highly cherished due to its strong strength-to weight ratio and resistance to corrosion. It is a top material selection for motorcycle sprockets, especially in racing cases where weight loss becomes important.

Thus, the type of material selected will depend on factors like motorcycle purpose thereby influence performance and environmental condition. On manufacturers’ part, a balance of strength, weight as corrosion resistance and cost is made to meet the necessary specifications.

Finishes Suitable for CNC Motorcycle Sprockets

The finish selection of CNC motorcycle sprockets contribute to the increase in their performance, reliability and aesthetics.

- Black Oxide: The sprocket receives black, corrosion-resistant finish because of the Black oxide coating. In addition, it enhances the wear resistance and appearance of a sprocket.

- Anodizing: Common aluminum sprocket finish is anodizing. The surface undergoes the formation of an oxidation layer that improves corrosion inhibition and offers a wide variety in appearances.

- Zinc Plating: The principal mechanism for protection against the corrosion of steel sprockets is zinc plating. It has a good life span and is applicable in thick layers.

- Powder Coating: The advantages of powder coating include long life and individuality. It can be bought in a variety of color options, reducing the effects on environmental wear and tear.

- Nickel Plating: The nickel plating provides protection against corrosion and makes the sprocket look better. It is frequently used for the steel or brass sprockets.

- Painting: Painting represents one of the best solutions in terms of costing, color and some corrosion resistance for motorcycle sprockets. But, it may not last as long others.

- Polishing: Surgical polishing is used in the processing of stainless steel sprockets for a high-gloss finish. It makes the sprocket look better and offers a little corrosion protection.

The selection of finish is influenced by factors such as the material used in sprocket, intended purpose,aesthetics and costs. Selecting the proper finish ensures only good performances from the motorcycle sprocket as well makes it pleasant to look at and durable.

Properly Replace Your Motorcycle Chain and Sprockets

- Removing the Previous Chain: Utilize a chain breaker tool to disconnect the old chain and detach it from the motorcycle. Gently slide the chain off both the front and rear sprockets.

- Remove Old Sprockets:

Loosen and remove the bolts securing the front and rear sprockets. Slide off the old sprockets from their respective shafts.

- Install New Front Sprocket: Slide the new front sprocket onto the output shaft and secure it with the appropriate bolts. Use a torque wrench to tighten bolts according to the manufacturer’s recommended torque specifications.

- Install New Rear Sprocket: Slide the new rear sprocket onto the rear wheel hub and secure it with bolts. Torque bolts to manufacturer’s recommended torque specifications.

- Thread New Chain: Thread the new chain onto the new front and rear sprockets. Make sure the chain is correctly aligned and properly seated on the sprockets.

- Adjust Chain Tension: Adjust the chain tension by adjusting the rear wheel position using the chain adjusters on the swingarm. Refer to your motorcycle’s manual for proper chain tension specifications.

- Secure Master Link: If your new chain has a master link, follow the manufacturer’s instructions to install it securely. Use the chain breaker tool to rivet or clip the master link as required.

- Lubricate Chain: Apply chain lubricant or grease to the new chain to ensure smooth operation and extended lifespan.

- Test Ride and Final Check: Lower the motorcycle from the stand or lift. Take a short test ride to ensure the chain and sprockets are functioning properly. Double-check chain tension and alignment after the test ride.

Guide to Choosing Motorcycle Sprockets

- Explore gear ratios:

Gain insight into gear ratios and their effect on sprocket size variations. Choosing a smaller front sprocket or larger rear sprocket will result in a higher gear ratio (increasing top speed but reducing acceleration), while choosing a larger front sprocket or smaller rear sprocket will result in a more Low gear ratios (enhancing acceleration but reducing top speed).

- Consider terrain and riding conditions: Consider the terrain and road conditions you typically ride on. If you often ride in undulating or mountainous terrain, you may need a sprocket configuration with better climbing performance.

- Compute velocity and rpm: Use an online gear ratio calculator to estimate how different sprocket combinations will affect the speed of your motorcycle at a given rpm. This helps you better understand the impact of your choices.

- Balancing performance and practicality: While adjusting sprocket size can improve specific performance aspects, the practicality of the choice should also be considered. Extreme changes may sacrifice overall drivability or increase engine load.

- Test and Observation: If in doubt, start with a conservative chainring size change and see how it affects the performance of your motorcycle. You can then make further adjustments based on experience.

- Note the chain length: Changing the sprocket size may require adjusting the length of the motorcycle chain. Make sure the chain is not too slack or too tight for the new sprocket configuration.

- Long term consideration: Consider the durability and wear characteristics of the selected sprocket. Premium components may cost more upfront, but provide better durability and performance in the long run.

- Safety comes first:Keep in mind that drastic changes in sprocket size may affect braking performance, engine load and handling. Always make safety a top priority when making modifications.

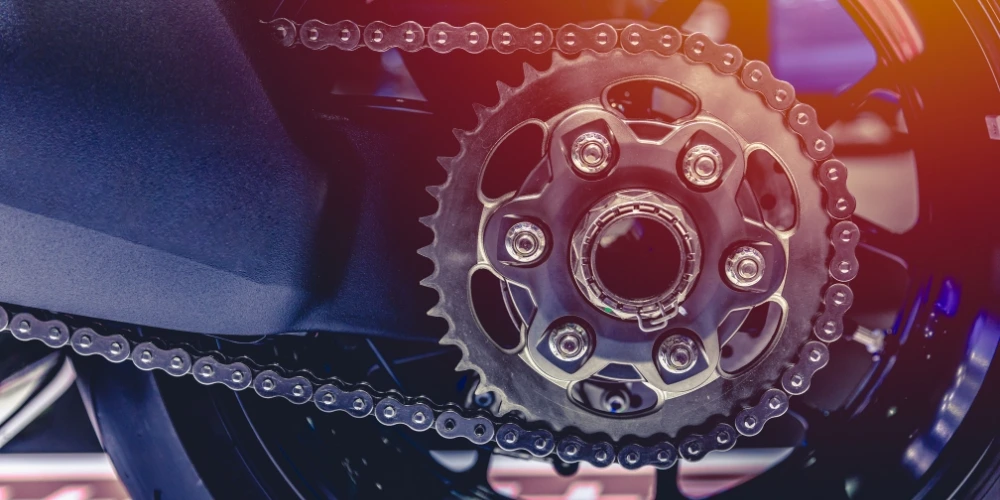

Work Principle of Motorcycle Sprockets

Work Principle of Motorcycle Sprockets

Motorcycle sprockets are a type of gear that is an essential component of the motorcycle drivetrain. They work in tandem with the chain to transfer the power generated by the engine to the rear wheel, thus propelling the motorcycle forward. The sprocket plays an important role in controlling the speed, acceleration and overall performance of the motorcycle.

Motorcycle sprockets are generally divided into two main types:

- Front Sprocket (also known as the Drive Sprocket): The front sprocket is linked to the output shaft of the motorcycle’s engine, constituting the front end of the transmission system. The size and number of teeth of the front sprocket help determine the gear ratio of the motorcycle’s transmission system.

- Rear sprocket (wheel sprocket): The size and number of teeth affect the final drive ratio of the motorcycle. The size combination of the front and rear sprockets determines the amount of torque delivered to the rear wheels at a given engine speed, affecting acceleration and top speed.

It’s worth noting that changing the size of the sprocket can also affect other aspects of the motorcycle, such as fuel efficiency, engine load, and handling. Riders often experiment with different chainring combinations to achieve a balance of acceleration and top speed based on their riding preferences and needs.

- Engine Power Transmission: The engine generates power and transmits it to the motorcycle’s drivetrain. The rider can switch between gears to control speed and power.

- Chain Drive: Motorcycle sprockets are connected by a chain. The front sprocket is tightly secured to the engine output shaft, while the rear sprocket is attached to the rear wheel hub. The chain winds around these sprockets.

Gear Ratio: The size of the front and rear sprockets of a motorcycle drivetrain determines its gear ratio. In the case of a larger front sprocket or a smaller rear sprocket, the gear ratio becomes lower, resulting in higher acceleration but a lower top speed. Conversely, if the front sprocket is smaller or the rear sprocket is larger, the gear ratio becomes higher, leading to a greater top speed while sacrificing acceleration.

Do I Need a New Chain if I Change the Sprocket Size?

It is usually possible to increase the total number of teeth by one or two by slightly moving the rear axle forward and keeping the chain length the same, but if the sprocket size changes by more than one or two teeth, the chain length will need to be increased. For example, if four teeth are added, the chain length will need to be increased by two links.

Choose the Right Size Sprocket for Your Motorcycle

The gear ratio is determined by the number of teeth on the front sprocket and the rear sprocket. As an example, a motorcycle with a front sprocket with 17 teeth and a rear sprocket with 45 teeth would have a ratio of 2.65 (45 divided by 17 equals approximately 2.65).

A Smaller Sprocket Size Increases Your Speed

Conversely, a smaller final drive ratio results in slower initial acceleration but higher top speed. Typically, using a smaller front sprocket and/or a larger rear sprocket translates into a smaller final drive ratio, which means better acceleration at the expense of top speed.

The Lifespan of Motorcycle Sprockets

Generally speaking, aluminum sprockets have a service life of about 10,000 to 30,000 kilometers; the actual life depends on how hard and how often you ride. It is also important to lubricate the chain regularly. Timely lubrication can extend the life of the chain and sprocket, so it is important to pay attention to it.

Changing the Front or Rear Sprocket To Increase Speed

Front gears or rear gears? Increasing the number of teeth on the front and rear sprockets will have the opposite effect. Selecting a larger front sprocket will increase the gear ratio, while a larger rear sprocket will decrease the gear ratio. Similarly, a smaller front sprocket will decrease the ratio, while a smaller rear sprocket will increase the ratio.

The Impact of Changing Sprockets on a Motorcycle Engine

The purpose of adjusting the sprocket size is to redefine the relationship between engine speed and road speed on the tachometer and speedometer. Using your motorcycle as an example, if the front sprocket has 18 teeth and the rear sprocket has 43 teeth, the ratio would be 43 divided by 18, or 2.39. Such an adjustment would affect the acceleration and top speed of the vehicle.

The Impact of Sprocket Tooth Count

Motion or an external force will drive the sprocket wheel, thus transferring energy or adjusting the torque and speed of a mechanical system. An increase in the number of teeth of the sprocket wheel allows for greater loads to be carried, but also creates more friction, which reduces operating speed.

The Reason for an Odd Number of Sprocket Teeth

To ensure even wear of the teeth and rollers, it is best to design the drive sprocket with an odd number of teeth, while an even number of chain links is preferred. (In this way, a tooth of the sprocket will not come into contact with a link of the chain on every rotation.)

The Rule for Sprockets

Normally, we follow the following principle when exchanging sprockets: reduce the front sprocket by one tooth and increase the rear sprocket by one tooth. As a rule of thumb, increasing or decreasing the front sprocket by one tooth has the same effect as increasing the rear sprocket by two and a half teeth.

Get High-Quality CNC Sprockets

You can find premium quality CNC sprockets in many different locations, but the best ones you can find in China – particularly here with us at HDC Manufacturing. For over a decade, we have been in the business of producing high-quality CNC parts and components for motorcycles, including sprockets.

Our sprockets aren’t just offered pre-made or pre-fabricated, you can customize your own, too! In fact, we produce anything from a conveyor sprocket, a universal CNC sprocket, and even a motorcycle sprocket!

We have weekly production reports, in-house engineering support, and even samples to help you get to what you need exactly!

- We have combined experiences of 15+ years in CNC machining and engineering

- ISO 9001-2015 Certified

- We service 50+ countries from North America, Europe, Australia, and New Zealand

Reach out to us and we’ll be more than happy to send over a free quotation for what you need!

Guidance for Custom CNC Sprockets

In manufacturing CNC sprockets based on a customer’s order, it is very important to provide specification clear and detailed information such as material composition, dimensions, tolerance etc. Transparently communicate your desired quantity, lead time and budget. Combine (collaborate) design if you need to, and review the options of ordering prototypes for evaluation. Ensure that you have worked out a good communication channel, agreed upon the terms of payment and gone through your contract with all necessary attention.

In manufacturing CNC sprockets based on a customer’s order, it is very important to provide specification clear and detailed information such as material composition, dimensions, tolerance etc. Transparently communicate your desired quantity, lead time and budget. Combine (collaborate) design if you need to, and review the options of ordering prototypes for evaluation. Ensure that you have worked out a good communication channel, agreed upon the terms of payment and gone through your contract with all necessary attention.

Also, make sure the manufacturer has quality control measures in place and that you talk about shipping charges or warranties. If these steps are followed and communication is kept open, you will get custom CNC sprockets that will meet your specific needs as wells as quality standards while fitting into your budget constraints of timeline.

Conclusion

In summary, this article discusses CNC motorcycle sprockets through the manufacturing process, selection of materials used to manufacture them as well as finishes that include polishing powder coat painting among others. It also discusses important issues to be taken into account when replacing the sprockets, as well as how one should select a suitable size of the sprocket for his motorcycle. The content underlines the need to make clear instructions for a custom CNC sprocket order from manufactures.

Resources:

CNC Processes Suitable for Machining Motorcycle Sprockets

CNC Processes Suitable for Machining Motorcycle Sprockets Work Principle of Motorcycle Sprockets

Work Principle of Motorcycle Sprockets