CNC Machining Aluminum Materials

HDC for Machining Aluminum

Aluminum is the most common material we machine every day, as Aluminum has perfect machinability and ductility, with good strength-to-weight ratio, low density, good electrical and natural corrosion resistance, also could be anodized to colorful colors

Why Choose Us

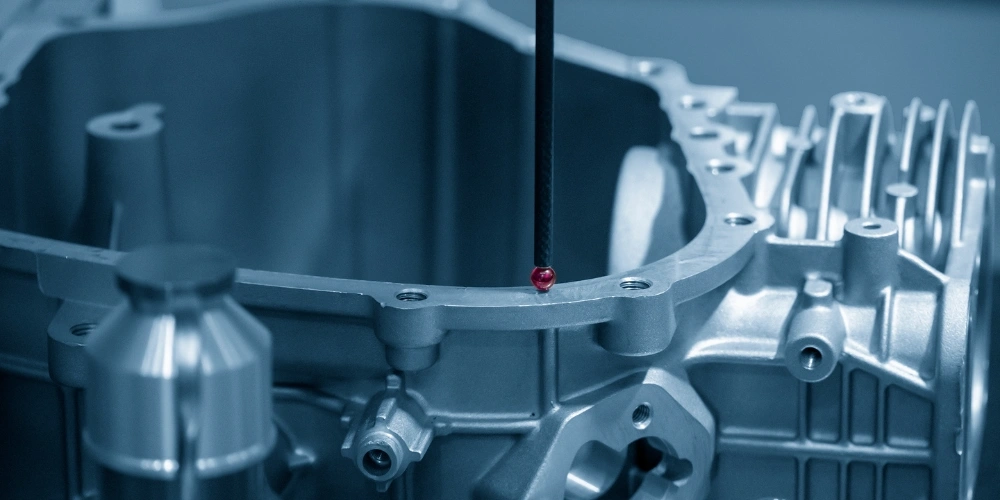

High Accuracy

Equipped with an industry-leading 5-axis machine and skilled technician team, we can meet your high precision requirements, not only in prototyping but also in production.

On-Time delivery

We make the delivery as promised schedule, we do as we said, we can the delivery for samples in 20 days and production in 30 days

Quality Assurance

We have an experienced quality control team to ensure all the measures within the tolerance As ISO9001 certificated manufacturer, we have a complete quality system from the material, machine, and surface treatment to packing.

Design Protected

We protect your designs, all your designs are not allowed to show to any third party, and will have a Non-disclosure Agreement with you

Available materials

EN AW-2007 / 3.1645 / AlCuMgPb

Aluminum 2007 is aerospace-grade aluminum, a high-strength alloy, currently not commonly used in other industries.

Aluminum 6060, medium strength, good corrosion resistance, good welding performance, widely used in the decorative industry

EN AW-7075 / 3.4365 / Al-Zn6MgCu

Aluminum 7075 It is also aerospace grade aluminum, which is a heat-treatable alloy and a super-hard aluminum alloy with good wear resistance, also most same as mild steel, It also has good weldability.

EN AW-6061 / 3.3211 / Al-Mg1SiCu

Aluminum 6061, is the most common use aluminum alloy. natural corrosion resistance.

excellent machinability, and good strength-to-weight ratio

EN AW-6082 / 3.2315 / Al-Si1Mg

Aluminum 6082, a very similar material to 6061, 6061 is more popular in North America, while 6082 is more often used in Europe

EN AW-5083 / 3.3547 / Al-Mg4,5Mn

Aluminum 5083 is low density, high tensile strength, high elongation, and good fatigue strength, which is one of the more mature aluminum sheet series.

Frequently Asked Questions (FAQ) – CNC Machining Aluminum Materials

Aluminum, maybe next or followed by steel, is known as the best and most reliable material to use for machining. Thanks to its wide flexibility, easy machinability, and its core strengths and properties, a lot of companies in various business sectors and industries use it.

Should you have questions about CNC machining aluminum, we here at HDC Manufacturing have prepared this FAQ guide for you to help you with any questions or concerns you might have regarding it!

Types of Aluminum Materials Used in CNC Machining

Many of the aluminum materials that are usually used in CNC machining can be mentioned. These include:

- Aluminum 6061: One of the widely used aluminum alloys for CNC machining is this one. It provides a good strength, weldability and corrosion resistant. It is compatible with many different uses.

- Aluminum 7075: This 7075 aluminum is widely famous for its strength to weight ratio with the usage in aerospace and high stress applications. It has a great machinability and may need some special consideration.

- Aluminum 2024: This alloy is appreciated for its strength and fatigue resistance. It’s widely used in the aerospace and military settings.

- Aluminum 5052: Due to its outstanding corrosion resistance, the 5052 aluminum is commonly used in marine and also automotive parts. This is weaker than some other alloys and gives good formability.

- Aluminum 6063: This alloy is very popular in the extrusions and architectural uses because of its excellent finish surface quality, high corrosion resistance.

- Aluminum 2011: With a great machining quality, the 2011 aluminum is used in manufacturing parts that are very complex and require accuracy.

- Aluminum 7050: Like 7075 aluminum, the 7050 offers high strength and durability. It is used for the construction of aeroplane structures and also high performance applications.

- Aluminum 3003: This material is mainly employed in the sheet metal manufacturing with a high formability.

- Aluminum 5083: 5083 aluminum is widely utilized in the marine applications due to its high strength and corrosion-resistance.

These are some of the aluminum materials used in CNC machining that were selected due to particular application needs and also ideal properties.

The Properties of Common CNC Machining Aluminum Materials

Aluminum 6061 Properties:

| Properties | Metric | English |

| Density | 2.7 g/cc | 0.0975 lb/in³ |

| Hardness, Brinell | 95 | 95 |

| Ultimate Tensile Strength | 310 MPa | 45000 psi |

| Tensile Yield Strength | 276 MPa | 40000 psi |

| Elongation at Break | 12% | 12% |

| Modulus of Elasticity | 68.9 GPa | 10000 ksi |

| Notched Tensile Strength | 324 MPa | 47000 psi |

| Ultimate Bearing Strength | 607 MPa | 88000 psi |

| Bearing Yield Strength | 386 MPa | 56000 psi |

| Poisson’s Ratio | 0.33 | 0.33 |

| Fatigue Strength | 96.5 MPa | 14000 psi |

| Fracture Toughness | 29 MPa-m½ | 26.4 ksi-in½ |

| Machinability | 50% | 50% |

| Shear Modulus | 26 GPa | 3770 ksi |

| Shear Strength | 207 MPa | 30000 psi |

Aluminum 7075 Properties:

| Physical Properties | Metric | English |

| Density | 2.81 g/cc | 0.102 lb/in³ |

| Hardness, Brinell | 150 | 150 |

| Ultimate Tensile Strength | 572 MPa | 83000 psi |

| Tensile Yield Strength | 503 MPa | 73000 psi |

| Elongation at Break | 11% | 11% |

| Modulus of Elasticity | 71.7 GPa | 10400 ksi |

| Poisson’s Ratio | 0.33 | 0.33 |

| Fatigue Strength | 159 MPa | 23000 psi |

| Fracture Toughness | 20 MPa-m½ | 18.2 ksi-in½ |

| Machinability | 70% | 70% |

| Shear Modulus | 26.9 GPa | 3900 ksi |

| Shear Strength | 331 MPa | 48000 psi |

Aluminum 6063 Properties:

| Physical Properties | Metric | English |

| Density | 2.7 g/cc | 0.0975 lb/in³ |

| Hardness, Brinell | 73 | 73 |

| Ultimate Tensile Strength | 241 MPa | 35000 psi |

| Tensile Yield Strength | 214 MPa | 31000 psi |

| Elongation at Break | 12% | 12% |

| Modulus of Elasticity | 68.9 GPa | 10000 ksi |

| Ultimate Bearing Strength | 434 MPa | 62900 psi |

| Bearing Yield Strength | 276 MPa | 40000 psi |

| Poisson’s Ratio | 0.33 | 0.33 |

| Fatigue Strength | 68.9 MPa | 10000 psi |

| Machinability | 50% | 50% |

| Shear Modulus | 25.8 GPa | 3740 ksi |

| Shear Strength | 152 MPa | 22000 psi |

Aluminum 5083 Properties:

| Physical Properties | Metric | English |

| Density | 2.66 g/cc | 0.0961 lb/in³ |

| Hardness, Brinell | 85 | 85 |

| Ultimate Tensile Strength | 317 MPa | 46000 psi |

| Tensile Yield Strength | 228 MPa | 33000 psi |

| Elongation at Break | 16% | 16% |

| Modulus of Elasticity | 70.3 GPa | 10200 ksi |

| Compressive Modulus | 71.7 GPa | 10400 ksi |

| Poisson’s Ratio | 0.33 | 0.33 |

| Fatigue Strength | 159 MPa | 23000 psi |

| Fracture Toughness | 43 MPa-m½ | 39.1 ksi-in½ |

| Machinability | 30% | 30% |

| Shear Modulus | 26.4 GPa | 3830 ksi |

| Shear Strength | 190 MPa | 27600 psi |

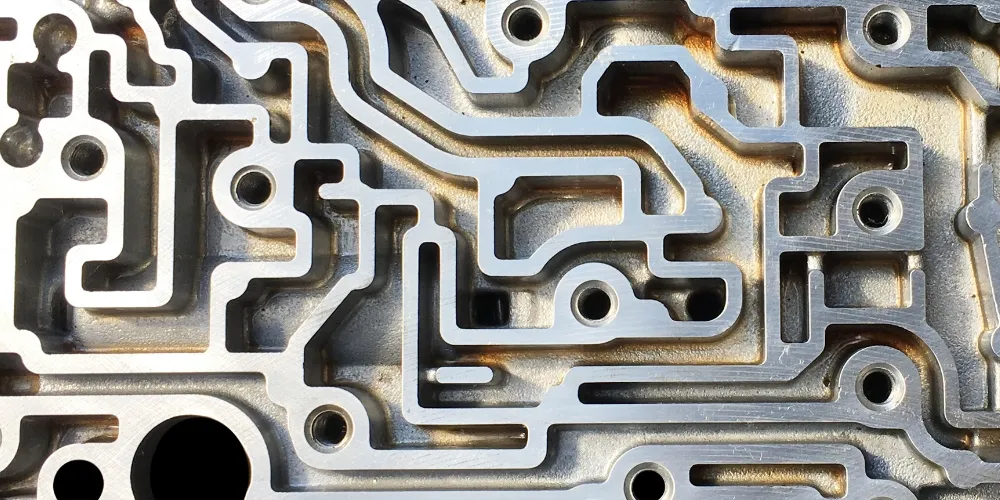

What Is CNC Machined Aluminum?

CNC means Computer numerical control, Aluminum is the commonly material we machine every day, as its perfect machinability and ductility

Which Aluminum Is Best for CNC?

It depends your demands, 6000 series material is one of the most popular materials for CNC machining

Is CNC Aluminum Strong?

Aluminum is very common machining material, strong enough for mechanica parts, Aluminum 7075-T6 is as strong as mild steel.

Can Aluminum Be Used for CNC?

Yes! In fact, aluminum is one of the most commonly used and machined materials by manufacturers simply because of the fact that they are cheap, they’re easy to find and source, and it is extremely machinable and weldable.

Many manufacturers consider it the Holy Grail when it comes to machining because of how easy and simple it is.

What CNC Processes Can You Use for Aluminum?

Simple – the usual and traditional manufacturing processes you do with it, you can CNC it, too. In case you require more information, the following are the most typical CNC processes that are done to aluminum in order to improve or develop it:

Milling

In the industrial sector, milling is considered one of the most common and most done processes because of the accuracy and precision that it has over other manufacturing processes. Akin to standard or regular milling, CNC milling can accurately carve, slice out, and shape the material into a shape that’s needed or wanted by the client.

Turning

Similar to milling, turning is also a great part of CNC processing. The difference it has with milling is that the toolhead or the cutting tool is the one that’s rotated and drilled against it – what this means is that the removal of the material will be extremely precise and accurate.

Plasma Cutting

Thanks to the high energy that plasma arcs have, it can pierce and slice through aluminum without any problem! Instead of slicing it, leading to a lot of crumbs on the surface, it melts away the material!

Laser Cutting

Laser cutting is similar to plasma cutting, but instead of utilizing a plasma arc, it vaporizes the material away. It’s almost similar to the process done in plasma cutting, but the difference would be in that of the energy – it uses less energy than a plasma arc.

Waterjet Cutting

Lastly, waterjet cutting is, so far, the cleanest and the neatest CNC machining process you can do to aluminum. It uses high-pressure water jets forced through a narrow nozzle, paving way for pressure and force.

These are the most common CNC processes you can use for working on an aluminum product or workpiece.

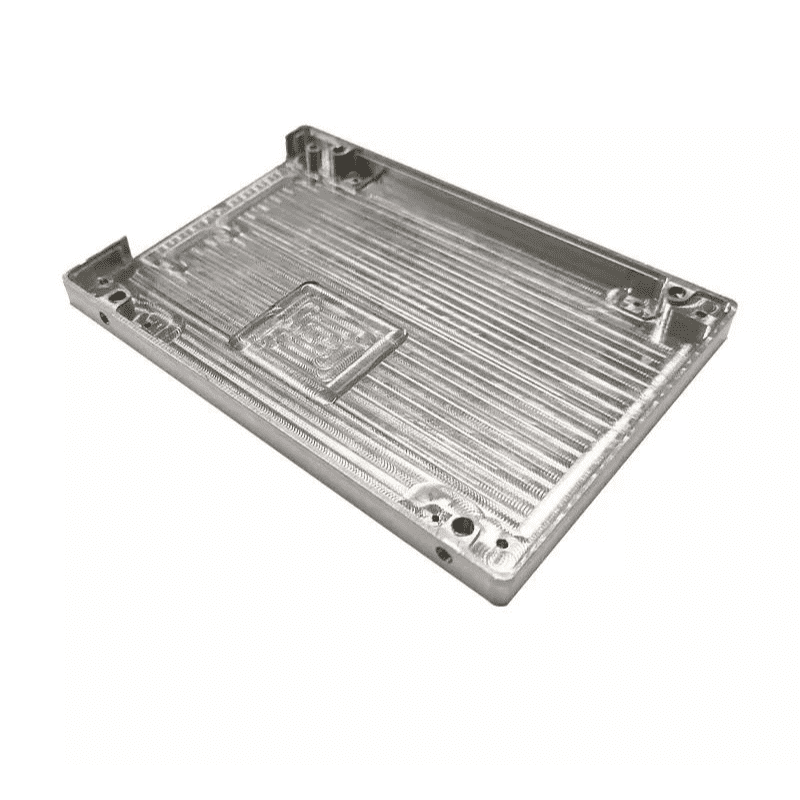

What Parts and Components Can You Produce Using by CNC Machining Aluminum?

CNC machined aluminum materials and products aren’t just categorized singularly. In fact, it can range from the simplest of components to the most complex! Part of these components include, but are not limited to:

- Rods

- Tubes

- Plates

- Bars

- Wires

- Billets

- Sheets

- And Many More!

CNC Machining Aluminum vs. CNC Machining Steel

These two (2) are the most common products battled when it comes to CNC machining because of how similar, durable, resistant, and highly flexible they are. But how do they differ? How can you choose which raw product or material to use?

Here is a quick rundown of some of the best properties between CNC machining aluminum and CNC machining steel.

- Strength-to-Weight Ratio – Aluminum is lightweight and easy to machine. It weighs only a third of steel.

- Corrosion – Aluminum, because of its passivation layer, is corrosion resistant. However, steel is more resistant to corrosion and oxidation.

- Thermal Conductivity – Steel has less thermal conductivity compared to aluminum.

- Material and Machining Cost – Steel (especially stainless steel) is costlier and more expensive than aluminum. Aluminum is such a cost-effective and cost-efficient material, and it only costs ½ or 1/3 of stainless steel’s price.

- Machinability– Aluminum is easy to cut, shape, and form. Stainless steels are generally harder and more difficult to machine and form

- Strength – Aluminum is strong, but steel is both physically and metaphorically stronger than it. This is a true case regardless of the weight of both products.

These are some of the differences between aluminum and steel. They’re not exactly directed towards CNC machining, but these properties contribute a lot on how they can be machined and processed.

Is CNC Machined Aluminum Strong?

Yes, CNC machined aluminum is strong – let alone standard aluminum is. If you want a more concrete and a more visualized measurement of strength, CNC machined aluminum melts at 640 degrees, it is an excellent conductor of electricity, and it is considered to have high levels of strength – that even sometimes, it can be comparable to steel.

This, of course, is something general. You can’t actually rely on it if you’re talking about raw and pure aluminum and steel.

Where Can You Get Premium Quality CNC Machining Aluminum Materials?

If you’re looking for high-quality aluminum materials made from CNC machining, HDC Manufacturing is a company you definitely want to work with! Being in the industry for 15+ years, you’ll never have problems dealing with operators from our company or manufacturing plant.

Wherever you are in the world and no matter how complex the industry you are in, we’ll be more than happy to help you get the necessary knowledge, skill, and items you need!

Other than our CNC machining aluminum capabilities, you can also bank and count on us if you find yourself in need of sheet metal fabrication services, aluminum forging, CNC machining steel and stainless steel, and many more!

Never will you find anything disappointing when it comes to our CNC machining aluminum materials. Reach out to our team and we’ll give you premium products without actually burning a hole in your pocket!

Conclusion

CNC machining aluminum is a very diverse and economical solution for many different parts of the components. The fact that it is very machinable, strong and also flexible makes this material an ideal choice for many industries. Over the 15 years, HDC Manufacturing has provided premium-grade CNC machining aluminium materials and also a number of other services. HDC Manufacturing is your go-to partner for rods, tubes, plates or any other customized component. With their experience and dedication to quality, you can trust them for all of your CNC machining services without having any need to stretch a dollar.

[toc]