CNC Prototyping Service

The best method to make prototypes is through Computer Numerical Control machining. Engineers and machinists are using CNC prototyping especially when a component requires tweaking prior to the phase of production.

There are two types of prototyping, the looks-like prototype, and the engineering prototype. The looks-like prototype is commonly applied to develop display or exhibit replicas, concept demonstrations, etc. An engineering prototype is produced to be practical and therefore settled under pressure.

HDC CNC Prototyping Service

HDC is a company that produces prototype components for every industry such as aerospace, medical, electronics, and the like. We can guarantee you parts that are resistant to wear, tear, and heat, as well as having exceptional strength and economical prices.

Your prototype parts from HDC are surely functioning and look the same as the original component. We are here to manufacture lifetime guaranteed prototype parts and give you the most special customer accommodation.

With its vast experience and expertise, HDC has the ability to make parts using various metal materials like aluminum, steel, stainless steel, brass, copper, carbon steel, etc. We also have plastic materials like HDPE, nylon, polycarbonate, Delrin, etc.

Our machinists and experts acknowledge the required understanding and comprehension when it comes to the geography and designs of each part, along with the machine’s function and performance.

In regards to additional characteristics, durability, and features of the prototyped product, whether it be customized or not, HDC offers marvelous surface treatments. Our company has tumbling, bead blasting, painting, passivating, engraving, polishing, brushing, powder coating, heat treating, anodizing, and more!

We know that you are here to know whether or not we are the kind of supplier you are looking for. HDC, being an ISO9001 certified manufacturer of CNC prototyping service, will never let you have an unreliable component.

Why choose HDC?

HDC is definitely one of the most trusted suppliers of machined prototypes as we have equipment and machines that help us to manufacture superior, precise, and error-free functional prototype components.

You can attain a fast turnaround as well as impeccable prototype parts with HDC’s engineering-grade metal and plastic raw materials. We are producing reliable and exceptional components for our clients in different parts of the globe.

No matter what application or industry you are in, HDC will always go above and beyond to develop your custom prototype parts. CNC prototyping service from HDC is considered by our clients as one of the finest because of the advantages that it imparts to the components that you desire.

Our team offers engineering consultations in order for you to know more about the processes, materials, and other matters of your custom parts. HDC will assure you that we can keep up maintaining highly reliable materials and consistently outstanding prototype processes.

As we want you to experience total convenience, HDC ensures that you’ll have different options regarding shipping, payments, and trade terms. We have courier, sea shipment, and air shipment. HDC offers Paypal, T/T, and L/C for payment methods, and FOB, CFR, and DDP for trade terms.

CNC Prototyping Service FAQS

In manufacturing, people wouldn’t be satisfied with their final products if they haven’t set it up for prototyping. So, we here at HDC Manufacturing capitalized on this strategy and placed one of our focus services in CNC prototyping.

For this FAQ guide, we will guide you through thick and thin – from A to Z. We’ll help you understand the CNC prototyping service more than you do now!

What Does CNC Prototyping Mean?

In the simplest of terms, CNC prototyping is a type of machining process that is used before producing or manufacturing a single piece or a small batch of a product.

The necessity of CNC prototyping lies within the effectiveness and efficiency of a product. Let’s say that your product has successfully been market researched and has been virtually tested, it still needs to undergo prototyping to further inspect and assess its overall efficiency and effectiveness.

CNC prototyping – or even prototyping in itself – reduces the impact of loss before releasing products.

Is CNC Prototyping the Same as Samples?

Yes and no – let me explain.

Prototypes, in layman’s terms, are the FIRST SAMPLES before even starting the production process regardless of the volume. This means, even before the product has undergone feasibility testing, effectiveness testing, and even market research, it will be produced and prototyped.

The primary purpose of prototypes is to ensure that the merchandise or the products fit the description that is needed by the market of the client and to see how it will play out.

Samples, on the other hand, are typically done right before or during production. Compared to prototypes, the main purpose of samples is to check the product in development – not even before starting its manufacturing or developing procedures.

Don’t confuse yourself in understanding prototypes from samples. Always remember that prototypes typically appear even before everything has been set for the manufacturing of the product, whereas samples are made to check its development and its exposure in the market.

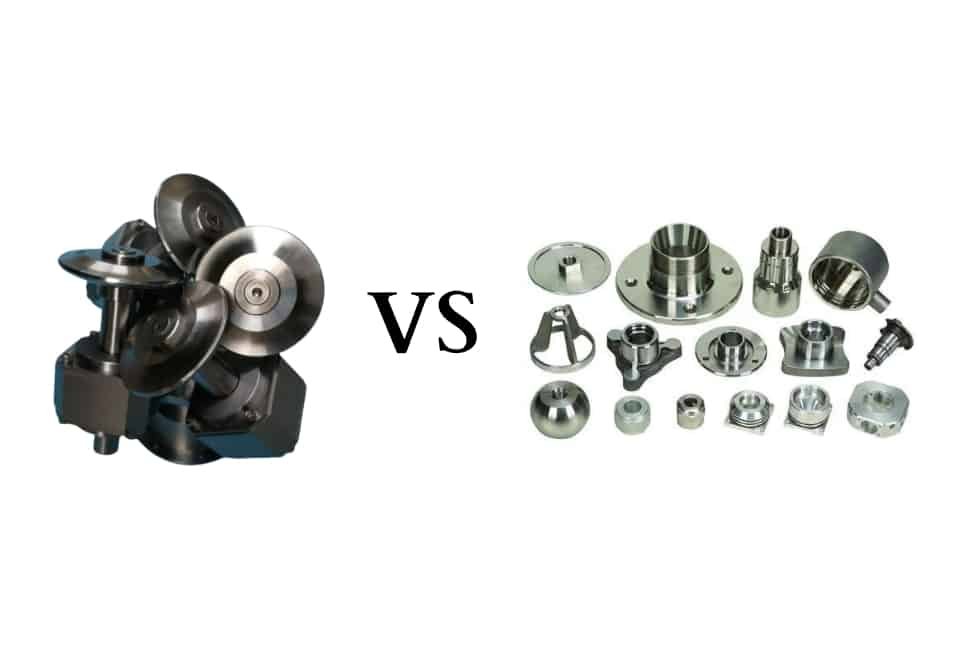

CNC Prototyping vs. CNC Rapid Prototyping

Many think that the single word – “prototyping” makes a huge difference in the area of manufacturing. So, in this question, we will be dwelling upon how both of them are different!

Many think that the single word – “prototyping” makes a huge difference in the area of manufacturing. So, in this question, we will be dwelling upon how both of them are different!

The simplest and most obvious answer to this question would be the speed – in traditional CNC prototyping, the prototypes are produced at a normal and regular rate, whereas in CNC rapid prototyping, the merchandise is usually produced at a much faster and more urgent rate.

How does this happen? Simple – Because of “HOW THEY ARE MADE.”

Traditional CNC prototyping makes use of simple CNC machines like CNC routers, mills, turning machines, and others. CNC rapid prototyping, on the other hand, makes use of highly advanced CNC machines, typically those that have more than one (1) axis.

What Are the Applications of CNC Prototyping?

The idea behind CNC prototyping is so relevant that without it, many businesses and industries today would not prosper and continue to develop. To name and cite a few of the MANY different applications of CNC prototyping, they include:

- The Medical, Medicinal, and Pharmaceutical Industries

- Automotive, Motorcycle, and Aerospace Industries

- Military and Defense Sectors

- Marine and Maritime Industries

- Oil and Gas Industries

- Technology and Telecommunications Industry

- Chemical Industry

- And Many More!

Advantages of CNC Machining Prototyping

CNC machining prototyping has its own fair share of pros and advantages. The most common of these are:

- The prototypes are highly precise and accurate

- All processes have an urgency

- They’ll surely be compatible with a lot of different materials and components

- Quality will never be an issue

Disadvantages of CNC Machining Prototyping

On the flip side of things, there also are a couple of drawbacks and disadvantages to CNC prototyping, these are:

- Since they’re prototypes and they’ll be controlled by computers, there will be restrictions on the shape, form, or geometry of the prototype

- There’ll be more waste material because the product would not be manually adjusted by an operator

- It will cost more than the usual and regular prototyping processes

As you can see, these advantages and benefits clearly outrun and outweigh the cons that are involved in CNC prototyping!

Are Chinese Prototyping Services Reliable?

Yes, as a matter of fact, Chinese prototyping services are considered the best and the most reliable in the market today. Besides the fact that they have the cheapest and most affordable offers, they also have all the resources needed that manufacturers from other countries would still have to order overseas – even from China.

Nothing is perfect – you will still be able to find a couple of drawbacks to patronizing Chinese CNC prototyping services, but one thing we can assure you of is that it will be within your budget.

Where Can You Get the Best and Highest Quality of CNC Prototyping Service?

Being in business for more than a decade, we here at HDC Manufacturing have been trusted by numerous companies, businesses, and organizations not only in China but also in other foreign countries. We’re so trusted that we were able to help and assist all our clients with the prototyping services they needed!

Our capabilities in CNC prototyping include working on aluminum, steel, copper, and even low-carbon to mild-carbon steel. But wait, there’s more! HDC Manufacturing’s capabilities aren’t just limited to that – we’re also seasoned and experienced in working on other materials like polycarbonate or PC, high-density polyethylene or HDPE, nylon, Delrin, and many more!

If you are trying to look for an all-around CNC prototyping service provider that has all the necessary tools, materials, and equipment, HDC Manufacturing will always be a click away.

Apart from our continuous development in the business of CNC prototyping, we are also China’s go-to for other services such as aluminum forging, laser cutting services, 5-axis CNC machining services, and many others!

Don’t hesitate to dial us, leave us a message, or shoot us a chat if you need help with budgeting! Contact us and we’ll send a free quotation over to you!

[toc]