High-Strength Carbon Steel Solutions

Specializing in cost-effective carbon steel machining and fabrication, we deliver components that balance strength and affordability.

Why Choose Carbon Steel

Cost Efficiency

✅40% lower material cost vs stainless steel at equivalent strength

✅Optimal price-to-performance ratio for high-volume production without structural compromise

Versatile Grades

✅50+ standard grades (1018/1045/4140 etc.) covering 90% industrial needs

✅From low-carbon weldable sheets to high-strength shafts, find the perfect match for your application

Machining Superiority

✅30% faster CNC speeds than alloy steels with extended tool life

✅Reduced cycle times and lower tooling costs for precision components

Why Choose HDC

Full In-House Production

✅Complete manufacturing from raw material cutting to final surface treatment

Flexible Material Selection

✅We work with all common carbon steel grades – from soft low-carbon Q235 to strong alloy steel 4140

Best Surface Treatment

✅6 proven surface treatments including black coating, zinc plating, and polishing.

Reliable Customer Support

✅24/7 support in multiple languages, get clear answers within 12 hours.

Hassle-Free Shipping

✅We handle all export paperwork and offer FOB/CIF options to get your parts safely to any port.

No-Risk Guarantee

✅ Every order comes with free replacement for manufacturing defects.

Carbon Steel Selection Guide

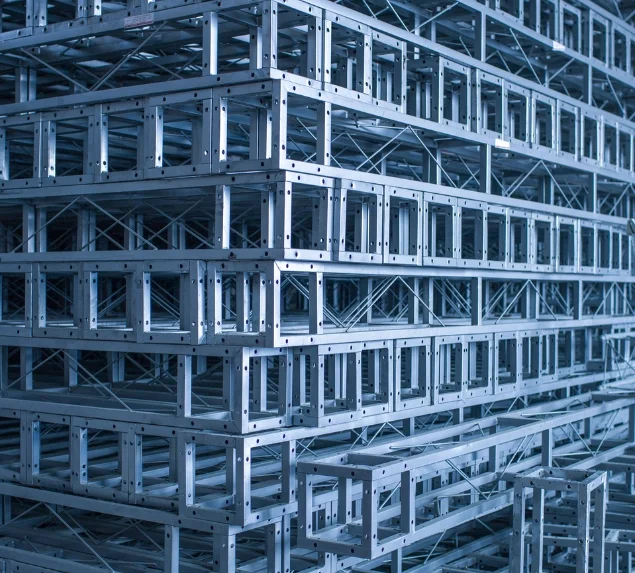

Precision-Crafted for Industrial Durability

Explore our 8 most utilized carbon steel grades, engineered to deliver:

✅ Superior Strength-to-Cost Performance

✅ Machining-Adaptive Properties

✅ Heat-Treatment Versatility

Struggling to balance budget and performance?

Our Precision Manufacturing Capabilities

From prototyping to mass production – optimized for aluminum's unique properties

CNC Machining

Capabilities:

±0.02mm precision on 1018/1045/4140 grades

Multi-axis milling for complex geometries

Equipment:

Mazak & DMG MORI CNC centers

Applications:

Gearbox housings

Custom shaft components

Welding

Capabilities:

Multi-process welding (MAG for Q235, TIG for 4130)

Stress-relieving for critical assemblies

Materials:

All grades from 1018 to 4140

Applications:

Structural beams

Pressure vessel skirts

Sheet Metal Fabrication

Capabilities:

0.5–12mm thickness handling

Laser cutting (3kW fiber) with ±0.1mm repeatability

Finish:

Powder coating & galvanizing options

Applications:

Equipment enclosures

Heavy-duty brackets

Carbon Steel Products at HDC

Uncover the wide-ranging applications of carbon steel in various sectors.

FAQ

Discover key facts and common questions about carbon steel in our concise FAQ section.

Carbon steel is favored for its versatility, strength, and affordability. It can be hardened and strengthened through heat treatment, making it ideal for a wide range of applications including construction, automotive, and machinery manufacturing.

There are three main types of carbon steel: low carbon steel (up to 0.3% carbon), medium carbon steel (0.3% to 0.6% carbon), and high carbon steel (0.6% to 2.5% carbon). Each type offers different levels of strength, ductility, and hardness, making them suitable for different applications.

The amount of carbon in carbon steel significantly impacts its properties. Higher carbon content increases hardness and strength but reduces ductility. Low carbon steel is more malleable and easier to weld, while high carbon steel is more suitable for high-strength applications but is less ductile and harder to form.

Carbon steel is less resistant to corrosion compared to other steel types like stainless steel. However, it can be coated or painted to protect against moisture and prevent rust. In environments where corrosion is a concern, proper finishing and maintenance are crucial to prolong the lifespan of carbon steel products.

Carbon steel is highly recyclable, which makes it a more environmentally friendly option compared to many other materials. Recycling steel requires significantly less energy and resources than producing new steel from raw ore, thus reducing its environmental footprint.

Explore More Materials Offered by HDC

Beyond aluminum – specialized metals and composites

for demanding applications

Get an Instant Quote!

Get a quick quote for your project with just a click! Request an instant quote now!

Contact With Us

for any inquiry