Certified Aluminum Alloys, Precision-Crafted for Global Compliance

From prototype to production: Get lightweight, corrosion-resistant aluminum components with guaranteed traceability. 90% of orders ship on time – or we compensate delays.

Why Choose Aluminum

The Lightweight Champion

✅Density: 2.7 g/cm³ (1/3 of steel’s weight)

✅Perfect for weight-sensitive applications: drone frames, automotive parts, portable devices.

Super Corrosion Resistance

✅5x more resistant to salt spray than standard steel

✅Ideal for harsh environments: marine hardware, outdoor enclosures, chemical equipment.

Cost-Efficient Machinability

✅40% faster processing speed vs. titanium

✅Rapid prototyping & production: complex geometries, small-to-medium batch orders.

Why Choose HDC

Material Quality Assurance

✅Material certifications (RoHS, MSDS) provided upon request.

✅Batch-level inspections to ensure compliance with specifications.

Needs-Driven Collaboration

✅Dedicated project manager for 1-on-1 support.

✅DFM report included to optimize designs for manufacturability.

Precision Guaranteed

✅5 Axis CNC machining accuracy: ±0.02mm (ISO 2768-m standard).

✅Full CMM inspection for critical dimensions.

End-to-End Solutions

✅Full-service capabilities: CNC, 3D printing, sheet metal, surface finishing.

✅Seamless multi-process integration (e.g., “CNC + anodizing + laser engraving”).

Design-to-Reality Expertise

✅Cross-Industry Experience: 500+ projects in medtech, aerospace & robotics.

✅Professional team, following a strict design-to-production process

Risk-Free Commitment

✅Free rework/replacement for material-related defects (shipping costs covered).

✅Commit to Product Quality and customer satisfaction.

Aluminum Alloy Selection Guide

Precision-engineered for your industry's toughest demands

Explore our 8 most requested aerospace-grade alloys, rigorously tested to deliver:

✅ Optimal Strength-to-Weight Ratios

✅ Customizable Surface Finishes

✅ Batch-to-Batch Consistency

Need help matching materials to your application

Our Precision Manufacturing Capabilities

From prototyping to mass production – optimized for aluminum's unique properties

CNC Machining

Our Equipment

HAAS 5-axis machining center

60-tool automatic changer

Positioning Accuracy:

±0.005mm

Max Workpiece Size:

800×500×300mm

Recommended Materials:

6061-T6; 7075-T6; 2014-T6

Post-Processing:

Anodizing; Hard anodizing

Metal 3D Printing

Our Equipment:

SLM / DMLS System

<0.1% oxygen inert atmosphere

Dimensional Accuracy:

±0.1%L (L≤100mm)

Max Build Size:

250×250×325mm

Recommended Materials:

Aluminum 6061 powder

Post-Processing:

Anodizing; Hard anodizing

Forging

Our Equipment

Press Capacity: 500-8,000 tons

Die Temperature Control:

±15°C

Max Part Weight:

85kg

Recommended Materials:

2014-T6; 6061-T6; 7075-T6

Post-Processing:

Ultrasonic testing; Anodizing

Sheet Metal Fabrication

6kW fiber laser cutter

Automated loading robot

Bending Accuracy:

±0.25°

Laser Cutting Accuracy:

±0.1mm

Recommended Materials:

5052-H32; 3003-H14

Post-Processing:

Anodizing; Hard anodizing

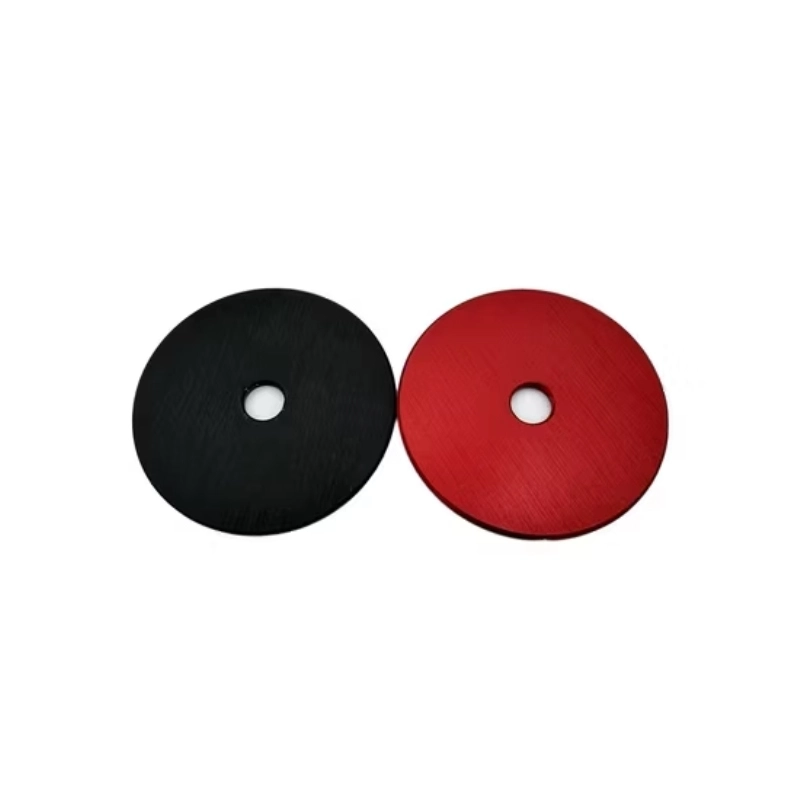

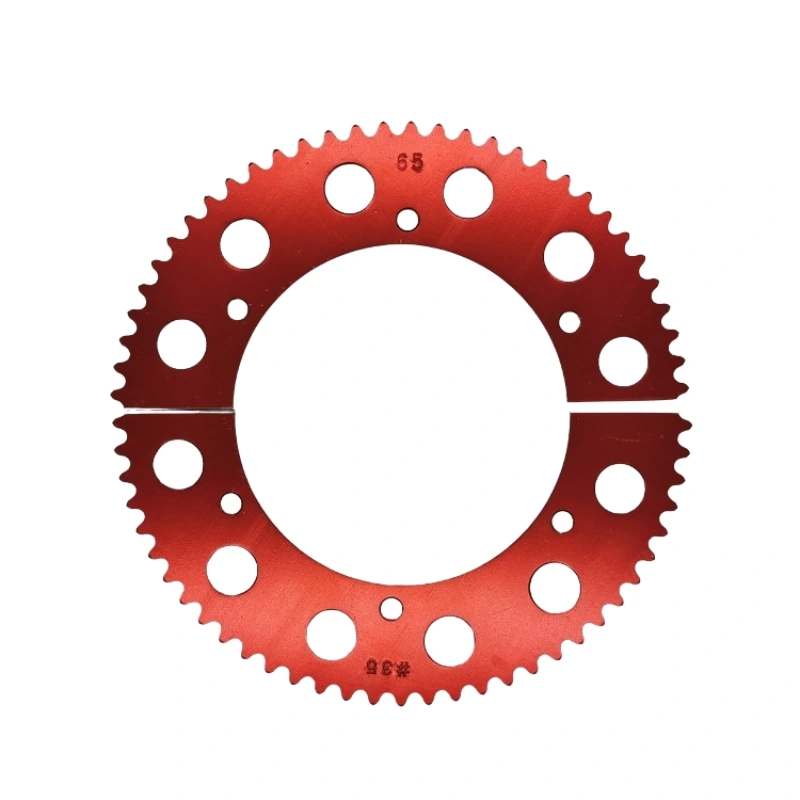

Precision Aluminum Components

Engineered for performance-critical applications. Our certified production line delivers mission-critical aluminum parts across industries

FAQ

We provide 8 industry-standard alloys: 2007, 2024-T3, 5052-H32, 5083-H116, 6061-T6, 6063-T5, 6082-T6, and 7075-T6. For specialized requirements, we source 40+ additional alloys through certified suppliers. Contact us for specific material needs.

We offer anodizing (standard/hard), chemical coatings, and sandblasting/texturing. Final selection depends on your part's manufacturing process. Contact our engineers for compatibility guidance.

Yes. All materials comply with ISO 9001 and RoHS standards. Material test reports with composition analysis are available upon request.

Prices vary by material type, order quantity, and complexity. Contact us for real-time quotes based on current market rates and your specifications.

We remake defective parts at no cost, cover return shipping, and provide failure analysis. Standard 12-month warranty applies.

Yes. We verify composition through spectrometer analysis, check hardness, and inspect for defects. Testing records are retained for 10 years.

Most alloys export freely. Aerospace-grade materials require permits; lead-containing alloys need documentation. We handle all export procedures.

Contact us with details for precise requirements.

Yes. We provide free optimization to reduce costs and improve manufacturability. Complex projects may require additional engineering services.

Get an Instant Quote!

Get a quick quote for your project with just a click! Request an instant quote now!

Contact With Us

for any inquiry

Explore More Materials Offered by HDC

Beyond aluminum – specialized metals and composites

for demanding applications