High Quality Go Kart Sprocket Provided by HDC

Currently, we produce a wide range of kart sprockets designed for a variety of applications.

Our 219 pitch kart sprocket is an excellent choice for kart racers, offering reliable and precise performance that can take on rough terrain and high speeds with ease.

Our #35 Sprocket is suitable for many uses, from repairs to custom builds, thanks to its durable construction and easy installation process.

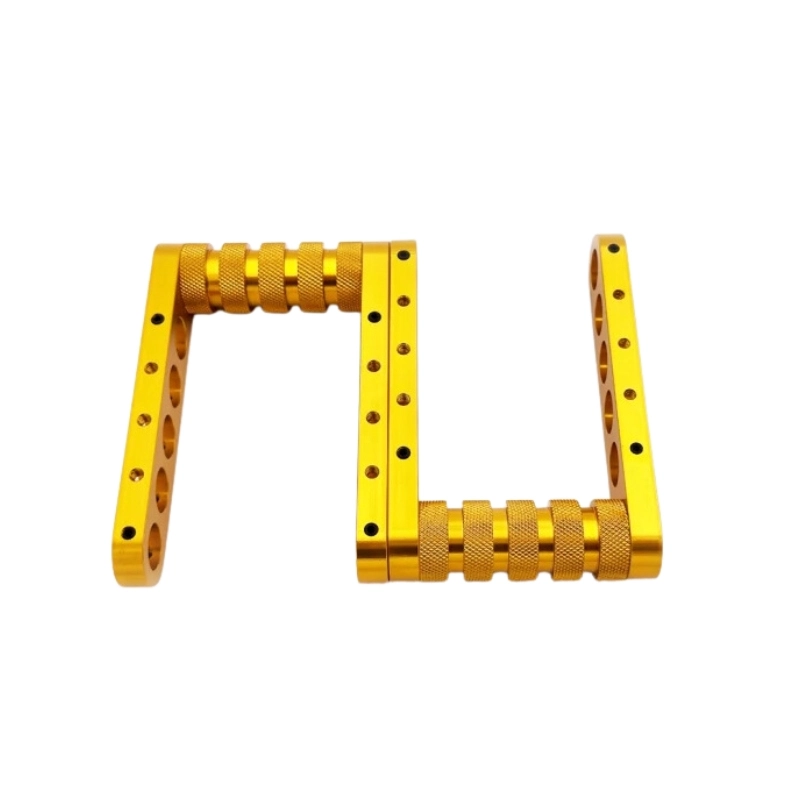

Finally, our axle sprockets are designed specifically for axle chain systems, providing strength and longevity even under extreme conditions. All our kart sprockets are made with quality Aluminum materials 6061,7075 and are backed by rigorous standards ensuring reliability and superior performance. With such outstanding features, you can count on us to provide you with the best possible sprockets available.

Different Types of Kart Sprocket Specifications

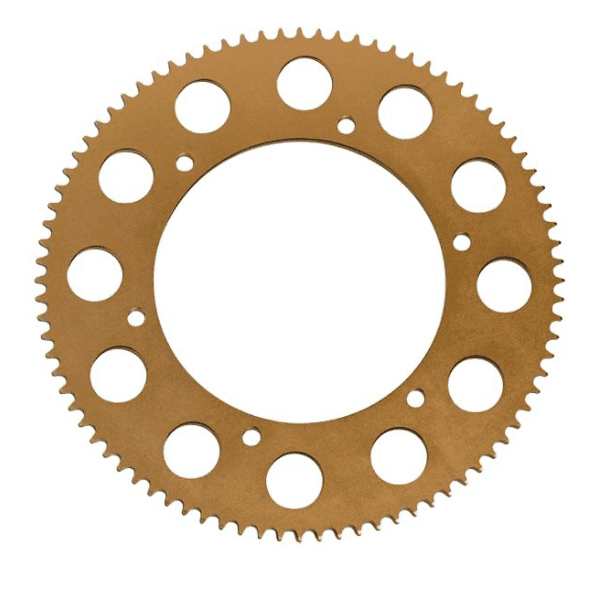

219 pitch kart sprocket produced from aluminum 6061-T6 or 7075-T6, both are high-quality and wear-resistant materials that will last you a long time while being compatible with your vehicle.

|

Material |

Surface Finish |

Size |

||

|

Normal Anodized |

63T-97T |

Color Anodizing |

Standard Design |

|

|

Aluminum 6061-T6 |

Hard Anodized |

63T-97T |

Dark Grey Anodzing |

Standard Design |

|

Normal Anodized |

63T-97T |

Black Anodizing |

Custom Designs available |

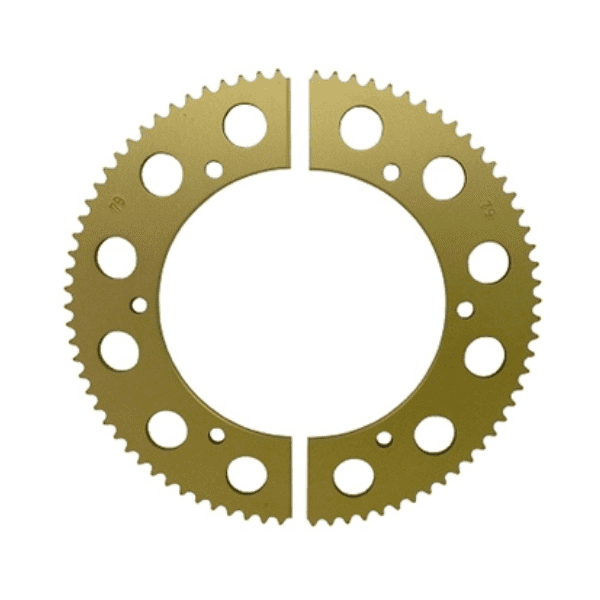

Our 35 Pitch Kart sprocket, is made of Aluminum 6061-T6, and the surface can be anodized to different colors, with a new and unique appearance while ensuring quality and reliability, it comes as split 2 pieces styles, also can be the whole one if needed.

|

Description |

Size |

Surface Finish |

|

|

Aluminum 6061-T6 |

53T-85T |

Color Anodized |

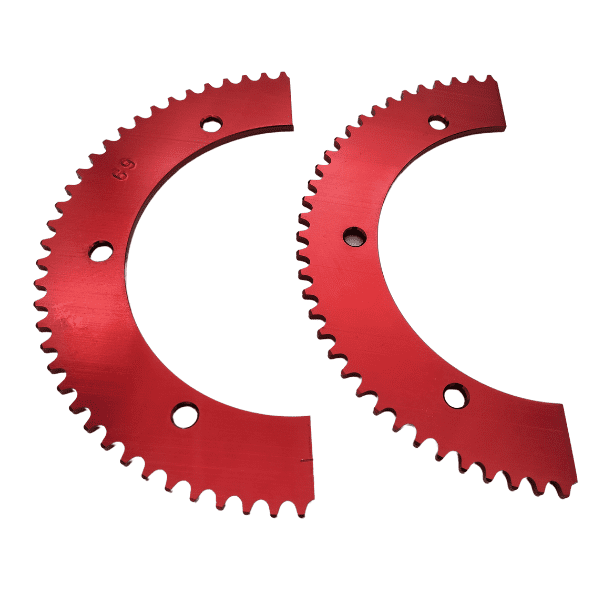

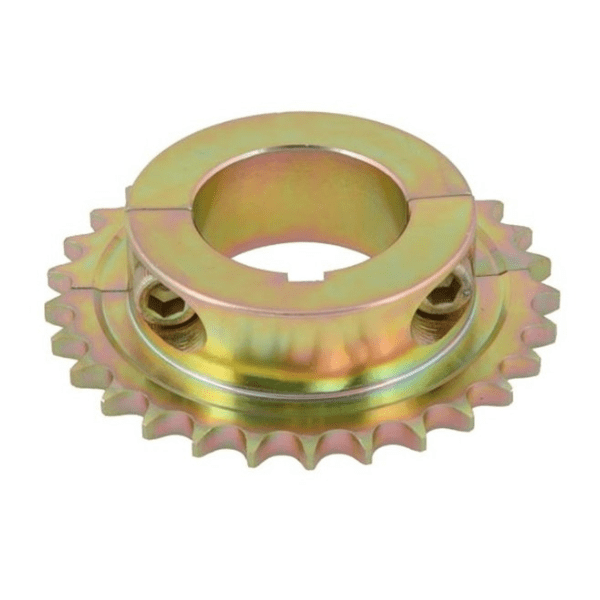

CNC 428 pitch sprocket, produced from AISI 1045 or Aluminum 7075-T6, the surface could be either Zinc plated or Black Anodized. we also can machine from your drawings to be compatible with your equipment.

|

Hole(mm) |

Teeth(T) |

Material |

Surface |

|

30 |

21-38 |

AISI 1045/Aluminum 7075-T6 |

Zinc Plating |

|

40 |

21-42 |

AISI 1045/Aluminum 7075-T6 |

Zinc Plating |

|

50 |

22-42 |

AISI 1045/Aluminum 7075-T6 |

Black Anodizing |

|

1. Split into 2 pieces |

|||

FAQs About Custom Wheel Spacers From HDC

Our focus is on machined kart parts, such as kart wheel hubs, sprockets, sprocket carriers, bearing housing, washers and spacers, clamps, and other machined go-kart parts. Additionally, we provide aluminum wheels, axle bearings, wheel bearings, cables, springs, kart seats, and steering wheels for go-karts.

Absolutely. We specialize in machining parts according to your designs, and your designs will be protected under non-disclosure agreements.

The MOQ varies depending on the type of part. Generally, we require 100 pieces for CNC go-kart parts, 30-50 pieces for each teeth of sprockets, 1000 pieces for springs and cables of each size, 100 pieces for axle bearings, 500 pieces for wheel bearings, and 200 pieces for steering wheels.

Yes, you can. If you believe the costs are workable, we can provide samples for quality approval. However, we may charge a samples fee if we need to produce the samples for you. The samples fee is refundable when mass production begins.

Yes, we ship worldwide using different shipping methods such as courier, air, or sea shipping. Based on the order quantity, we suggest the most suitable shipping method. Generally, the parts can arrive within two months.

Why choose HDC?

High Accuracy: Equipped with an industry-leading 5-axis machine and skilled technician team, we can meet your high precision requirements, not only in prototyping but also in production.

On-Time Delivery: We make the delivery as promised schedule, we do as we said, we can the delivery for samples in 20 days and production in 30 days

Quality Assurance: As ISO9001 certificated manufacturer,we have a complete quality system from the material, machine, and surface treatment to packing,to ensure all the measures within the tolerance.

Design Protected: We protect your designs, all your designs are not allowed to show to any third party, and will have a Non-disclosure Agreement with you