Custom Heavy Duty Barrel Hinge Provided by HDC

- HDCMFG

Barrel hinges have long been recognized for their durability and rotational flexibility, but when it comes to heavy-duty applications, the Heavy Duty Barrel Hinge takes the spotlight. In this guide, we delve into the intricacies of these robust hinges, exploring their advantages, load-bearing capabilities, materials, applications, and offering insights on choosing, installing, and even customizing these powerful components.

Components of Barrel Hinge

The barrel hinge is composed of several key components that collectively contribute to its unique design and functionality. These components include:

- Cylindrical Barrel: Central element enabling 360-degree rotation, distinguishing it from traditional hinges.

- Hinge Pin: Runs through the barrel, providing stability and facilitating smooth rotation.

- Mounting Plates or Brackets: Attached to the door and frame, ensuring stability and enabling rotational movement.

- Fasteners (Screws or Bolts): Secure the hinge to mounting plates, door, and frame, crucial for stability and functionality.

Understanding these components is crucial for selecting, installing, and maintaining barrel hinges effectively. Each element plays a specific role in ensuring the hinge’s durability, load-bearing capacity, and smooth operation.

Advantages of Barrel Hinge

Barrel hinges offer several advantages, making them a preferred choice for various applications. Here are the key benefits of using barrel hinges:

- durability for long-lasting performance

- High load-bearing capacity

- 360-degree rotation for flexibility

- Space efficiency

- Smooth operation facilitated by the hinge pin

- Versatility for various applications

- Minimal maintenance requirements

- Aesthetically pleasing design.

These features make barrel hinges a reliable and popular choice for a range of door configurations.

The Reason Barrel Hinges Can Bear High Loads

The ability of barrel hinges to bear high loads can be attributed to their structural design and load distribution mechanism. The cylindrical shape and robust construction of barrel hinges, particularly in heavy-duty variants, provide the strength needed to handle substantial loads. Additionally, the hinge’s design ensures an even distribution of the load, preventing stress concentration points and promoting balanced weight distribution. This combination of structural integrity and effective load distribution makes barrel hinges well-suited for applications requiring the handling of significant weights.

Materials and Finishes for Heavy-duty Barrel Hinge

When selecting materials and finishes for heavy-duty barrel hinges, it’s essential to consider factors such as durability, load-bearing capacity, corrosion resistance, and environmental conditions. Here are some recommendations:

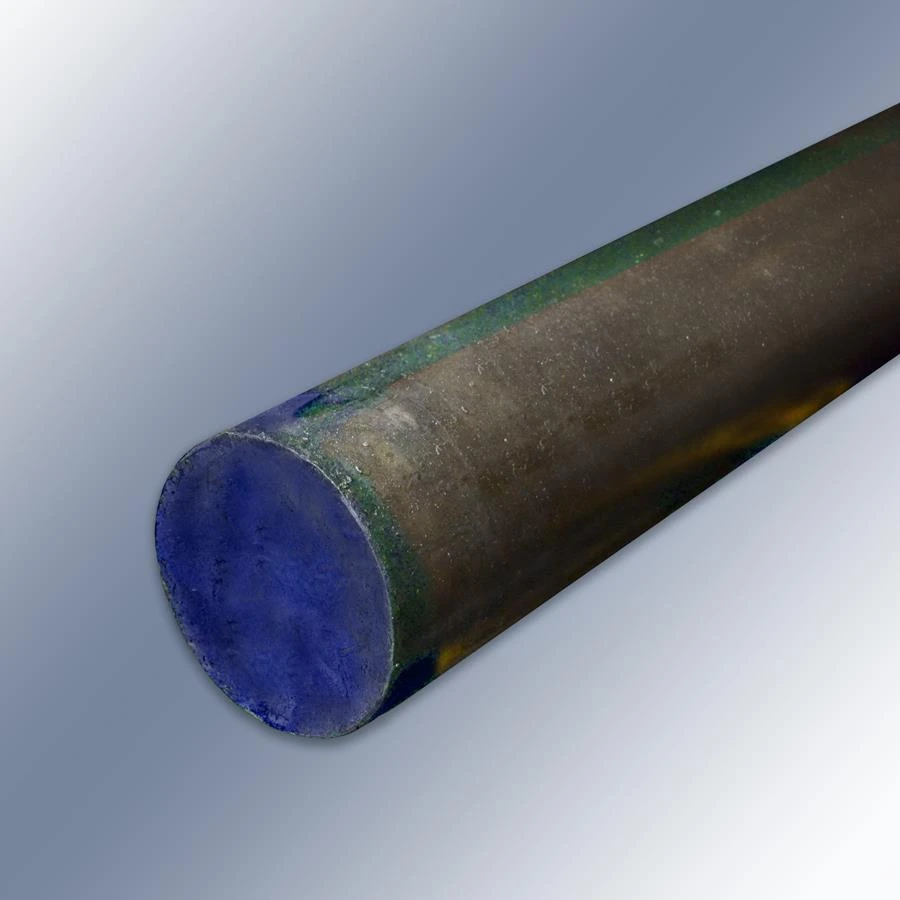

Materials:

- Stainless Steel: Excellent corrosion resistance, suitable for outdoor applications, with a higher cost for long-term durability.

- Carbon Steel: Strong and durable at a cost-effective price, though it is prone to corrosion, requiring additional coatings for protection.

- Bronze: Durable and corrosion-resistant, making it suitable for heavy-duty applications, albeit at a higher cost.

- Aluminum: Lightweight, corrosion-resistant, and cost-effective, suitable for various applications.

Finishes:

- Zinc Coating: Provides corrosion resistance but may wear over time, especially in high-friction areas.

- Nickel Plating: Enhances corrosion resistance and adds a decorative finish, but may wear in high-traffic or abrasive conditions.

- Powder Coating: Durable and corrosion-resistant with various color options, yet may chip or wear in high-friction areas.

- Hot-Dip Galvanizing: Offers excellent corrosion resistance for outdoor use, with a thick coating that can be visually uneven.

- Epoxy Coating: Provides corrosion resistance and durability but may chip in high-impact situations.

- Black Oxide: Enhances corrosion resistance and provides a sleek black finish, though it may wear over time, especially in high-friction areas.

Application of Heavy-duty Barrel Hinge

Heavy-duty barrel hinges are vital for robust, durable door and gate mechanisms in diverse applications. Widely used in industrial, commercial, and security settings, these hinges provide strength for large gates and doors, ensuring reliability in high-traffic areas. From estate entrances to barn doors and hangar doors, they offer stability and durability. The hinges also find application in automated gate systems, outdoor fencing, custom architectural designs, and marine environments, showcasing their versatility and importance in scenarios requiring durability and dependable performance.

Choose the Right Heavy-duty Barrel Hinge

Selecting the right heavy-duty barrel hinge is crucial for the longevity and performance of your door or gate. Consider factors such as material (e.g., stainless steel for corrosion resistance), load-bearing capacity, corrosion resistance, environmental conditions, and specific application requirements. Tailor your choice to the intended use, whether it’s an industrial gate, security entrance, or marine environment. Keep in mind your budget while weighing the advantages of each material and finish. By carefully evaluating these factors, you can ensure that the chosen hinge provides the necessary strength, durability, and resistance to environmental factors for your specific needs.

Installation Tips for Heavy-duty Barrel Hinge

Ensuring proper installation is essential for the optimal performance of heavy-duty barrel hinges. Follow these tips to achieve a secure and reliable installation:

- Positioning: Align the hinge precisely with the door or gate and frame as per manufacturer guidelines.

- Mounting Surface: Install on a flat, sturdy surface using appropriate anchors and fasteners.

- Leveling: Ensure the hinge is level for even weight distribution and increased longevity.

- Proper Gaps: Maintain correct spacing between hinge components and mating surfaces to reduce friction.

- Pre-drilling Holes: Pre-drill holes with the right size to prevent material damage during installation.

- Tightening Sequence: Gradually tighten fasteners evenly following the recommended sequence.

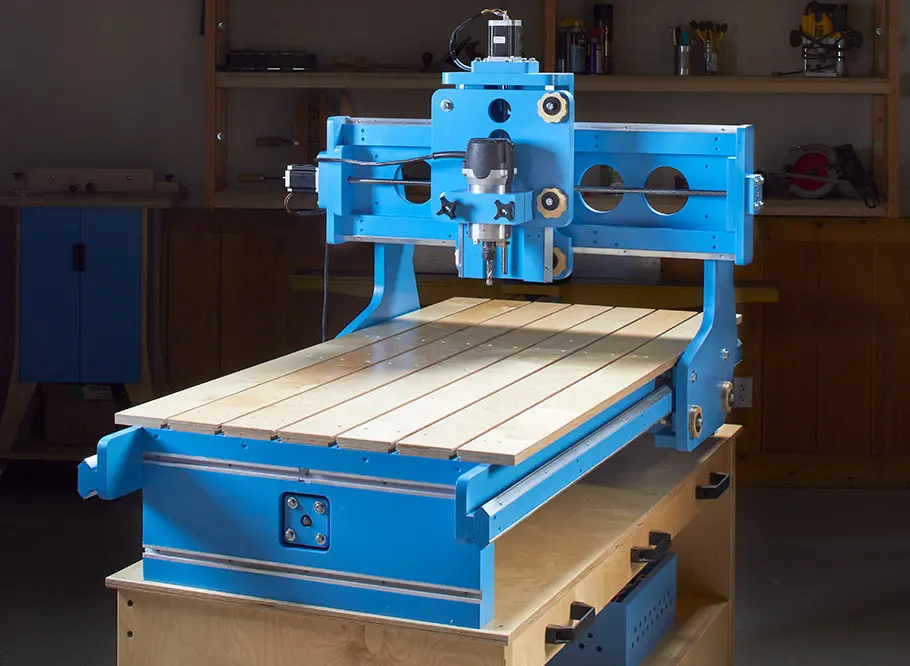

Custom Heavy Duty Barrel Hinge

When ordering custom heavy-duty barrel hinges from manufacturers, provide detailed design specifications, including size, load capacity, and desired features. Collaborate on material selection, finishes, and coatings based on environmental factors. Clearly communicate load-bearing requirements, precise measurements, and any specific installation considerations. Inquire about testing protocols, establish a budget, and confirm the estimated lead time. Maintain open communication throughout the process for a tailored hinge that meets your requirements.

Conclusion

The Heavy Duty Barrel Hinge stands as a robust solution for demanding door applications. With its unique design, high-quality materials, and customizability, it offers unmatched strength and reliability. Whether for residential, commercial, or industrial use, these hinges unlock a new level of durability, making them a prime choice for heavy-duty door applications.

Barrel Hinge Provided to Customers by HDC

Heavy Duty Black Iron Barrel Hinges, 5 Inch

Heavy Duty Barrel Gate Hinge Black Coated, 5 Inch

Black Coated Weld on Steel Barrel Hinge, 9 Inch

Weld on Steel Barrel Hinge, 2.1 Inch

Small Heavy Duty Steel Barrel Hinge, 1.2 Inch

Zinc Plated Steel Barrel Hinge, 6 Inch

Heavy Duty Weld on Steel J-Bolt Barrel Hinge, 5.5 Inch

Chrome-plated Bolt-On Barrel Hinge, 1.5 Inch

40+ Material Options

40+ Material Options