A2 tool steel is one of the industry’s most common grades of steel for toolmaking. It’s one of the building blocks and the fundamentals of toolmaking.

In case you wanted to know more information about A2 tool steel or if you have a specific question about it, this guide is perfect for you! This will be your go-to guide if you require any information about A2 tool steels, so, feel free to bookmark and save this!

Understanding What A2 Tool Steel is

A2 tool steel is an air-hardening steel known for its toughness and wear resistance. It belongs to the A-series of tool steels, which balance hardness and machinability.

It has high carbon content, offering hardness and wear resistance and chromium, which increases chemical resistance and edge-holding quality.

What makes A2 stand out is its ability to harden in air, reducing distortion during heat treatment. It provides a good mix of impact resistance and hardness, making it a reliable choice for demanding applications.

A2 Tool Steel Properties, Applications, Uses, and More!

Now that we know A2 tool steel up front, let’s delve deeper to further understand this steel type. In this part, we’ll be taking a look at A2 tool steel from the inside-out, discussing its tensile strength, yield strength, hardness, corrosion and temperature resistance, and more!

A2 Tool Steel Composition

A2 tool steel is an air-hardening, medium-alloy steel that is renowned for its ability to balance toughness and wear resistance. It contains approximately 1% carbon and 5% chromium, contributing to its hardness and stability during heat treatment.

A2 Tool Steel Properties

The following are the properties of A2 tool steels:

Hardness/Toughness

Because A2 tool steel is so resilient to stress and impact, they’re less likely to break under pressure. A2 tool steel hardness is rated 57-62 HRC, with a yield strength of 185 to 230 ksi. It offers great durability, thanks to its carbon and chromium content.

Low Friction

A2 tool steel naturally reduces friction, helping to minimize wear on moving parts. This property makes it a good choice for components that experience continuous contact and movement, improving efficiency and longevity.

Wear Resistance

A2 tool steel stands up well against friction and abrasion, ensuring longer tool life. Its high carbon content strengthens its ability to resist wear, making it ideal for heavy-duty industrial applications.

Heat Resistance

High temperatures don’t affect this steel’s ability to withstand deformation and remain stable. It is appropriate for tools subjected to friction and extended use because of its composition, permitting to tolerate extreme heat exposure without losing strength.

Thermal Conductivity

A2 steel has moderate thermal conductivity, meaning it retains heat longer than some other steels. While this slows down heat dissipation, it helps maintain consistent hardness, especially in applications that involve repeated heating and cooling.

Applications and Uses of A2 Tool Steels

As a well-known and excellent choice for specific industries, the following are some of its key uses:

- Manufacturing Industry:Used for making punches, dies, and shear blades.

- Automotive Industry:Ideal for engine components and stamping dies.

- Aerospace Industry:Used in producing turbine blades and aircraft parts.

- Plastic Molding:Common in molds and tools for plastic injection molding.

- Metalworking:Perfect for making cutting tools and machine inserts.

- Woodworking:Utilized in router bits and cutting edges for wood processing.

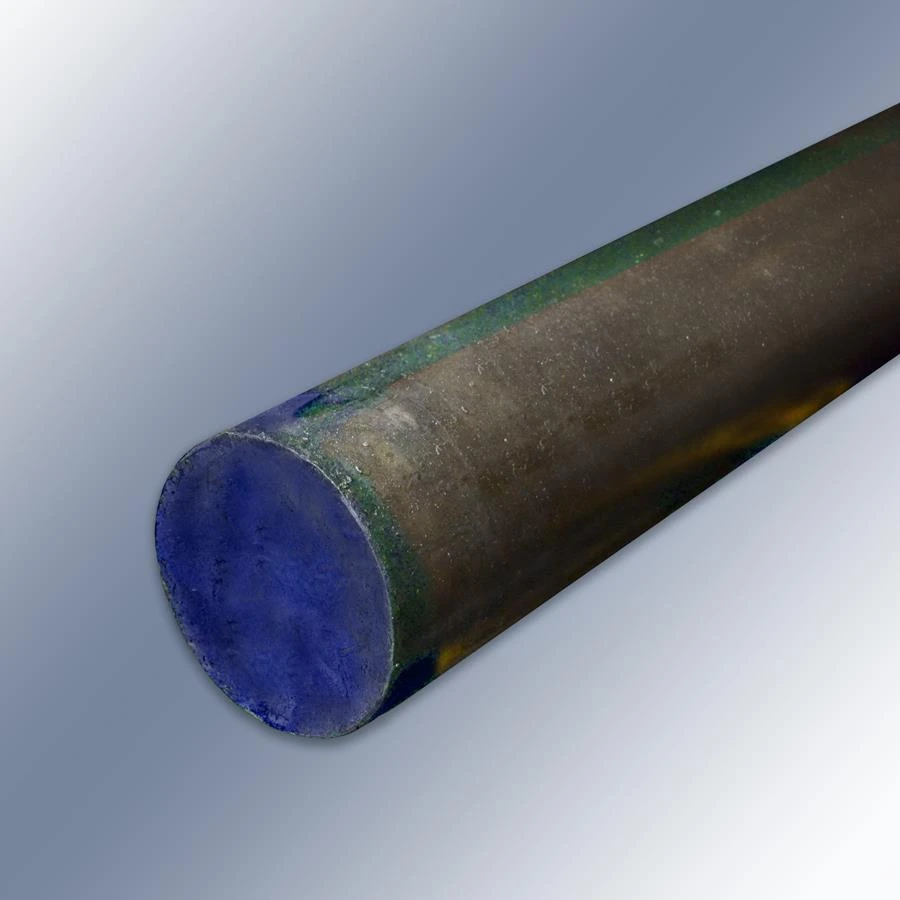

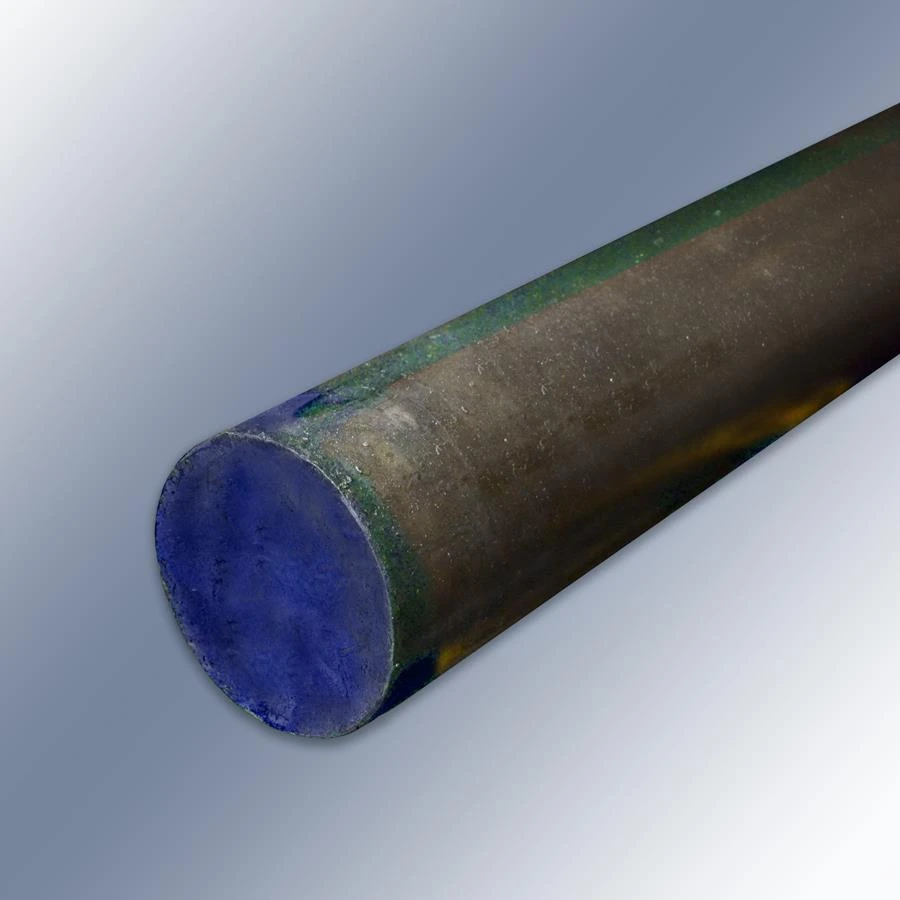

A2 Tool Steel Price

And last but most definitely not the least is its price and rate. The cost of A2 tool steel varies based on several factors, including size, shape, and supplier. Generally, raw A2 steel is priced per pound, with rates fluctuating due to market demand and material availability.

Bulk purchases and wholesale orders typically lower the price per unit, making it a cost-effective choice for manufacturers. However, heat treatment and machining add to the total expense.

A2 vs. D2 Tool Steel

Check this video out to see what D2 steel is!

When comparing A2 and D2 tool steel, both are high-carbon, air-hardening steels used for making tools and dies. However, they have some key differences that make them suitable for different applications. Let’s look at the table and see how they compare!

Feature | A2 Tool Steel | D2 Tool Steel |

Hardness | 57-62 HRC | 58-62 HRC |

Wear Resistance | Moderate | High |

Toughness | Excellent, ideal for shock resistance | Moderate, more brittle |

Applications | Dies, punches, cutting tools, and molds | Molds, dies, shear blades, and tooling |

Cost | More affordable | More expensive |

Can A2 Steel Be Forged?

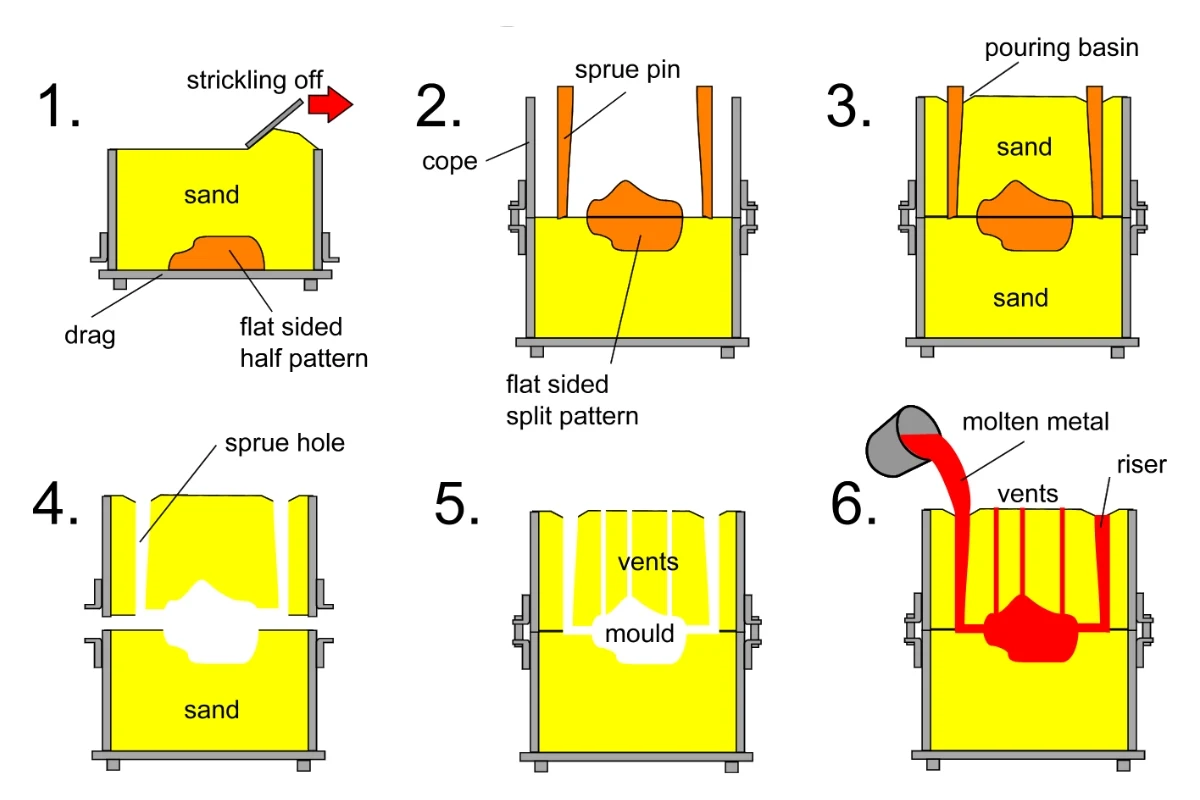

Yes, A2 steel can be forged. It’s a versatile tool steel that is ideal for forging at high temperatures. However, it sits at a weird spot because it’s challenging to do so.

To properly heat A2 steel, the temperature needs to be at 1,600 °F to 2,100 °F or up to 1,149 °C before forging to keep ductility and strength.

Order Your Next Set of A2 Steels From HDC!

Being the country’s best and most trusted CNC machining manufacturer, we can guarantee accuracy and precision over any steel. For 12+ years, our focus on producing top-tier quality A2 tool steel products remains implacable.

Our mastery in the metalworking industry serves as a cradle to all similar businesses. Contact us today and get a free estimate of the A2 tool steel you need! We can supply you flat, square, hot rolled, and cold drawn A2 tool steels!

Besides tool steels, you can also count on us if you need titanium alloys, stainless steels, carbon steels, and many more! Reach out to us and experience world-class-quality services! Get a quote within a few hours of your inquiry!

Discover more with our blog posts.

Recent Posts

Discover more about our products.

Related Products

Instant Quote!