The Complete FAQ of Titanium Parts

[toc]

Introduction

Titanium – the word came from the Greek word “Titans” which basically means the Gods. The strong material has the atomic number 22 in the periodic table and has an atomic weight of 47.87. The metal is now one of the most popular metals used in modern era industry-shaping with high durability, ductility and strength. Technically it is now ruling most of the metal industries along with stainless steel and aluminum.

What Is Titanium, And Why Is It A Popular Material?

Titanium is a very lightweight and highly durable metal that can be used to build many parts from many industries. From watches, earrings to aerospace parts, surgical and military equipment – titanium are being used everywhere nowadays.

The name came from the Greek word for Gods, “Titan”. So, we can understand the strength and durability behind this marvelous material. For the following reasons, titanium is a very popular material and being more and more popular day by day –

- As we have stated, you can find the material very strong but lightweight to work with. Compared to steel, a titanium bar is 40-45% lightweight.

- Parts made from titanium are rust and corrosion-resistant.

- Titanium can be easily alloyed with iron, molybdenum, or aluminum which makes it perfect for a vast range of industries.

- For lightweight, it has aerospace applications while for salt resistance, Titanium also has many underwater and marine applications.

Nowadays, it is one of the most popular metals in the market.

Why Use Titanium Machining Services?

For many reasons, you can use titanium machining Services. It is a very good metal to work with because of –

- Its high strength and durability but low density. For these reasons, it’s best to put in those parts where you need low weight but good strength.

- Lightweight and resistant to temperature makes it perfect for aerospace industries.

- For corrosion resistance and salt resistance, you can certainly use it in ships and boats which gives it underwater and marine applications.

- Last but not the least, even in watch industries, they are praised and appreciated for being lightweight on the wrists.

Moreover, as they can be alloyed easily with many other metals, machining them becomes quite easy.

What Are The Most Common Types Of Titanium Alloys?

Titanium alloys are very strong, durable, and lightweight. You can work with them very easily. The alloys can be categorized as Alpha, near-Alpha, Beta, and near-Beta alloys.

Grade 1-4 alloys are non-alloyed titanium that is low in strength but has high corrosion.

Among all the alloys, Grade 5 titanium Ti 6Al-4V is very popular to work with. Minimum 50% of the world’s titanium is used in this form. This is actually an Alpha-Beta alloy that has 6% aluminum, 4% vanadium, 0.25% iron, 0.2% oxygen in it. Most of aerospace fasteners, structures, and turbines are made of this alloy. Besides, engine parts, sports and marine equipment parts are also made with this alloy.

Ti 5Al-2.5Sn (Grade 6) is another alloy known for its applications in aerospace parts. It is a non-heat treatable alloy with much popularity to work with because of its durability, strength, and temperature tolerance.

Another alloy has versatile usage in different industries like aerospace, marine, and medical sectors. It is Ti Grade 9 (Titanium 3-2.5). Besides Titanium, it has 3% Aluminum and 2.5% Vanadium.

In the medical sector, the most used Titanium alloy is Ti 6AL-4V ELI (Grade 23). This can be easily molded and has good performance in bone and joint fixation surgeries.

Other popular alloys are Titanium Beta 21S, Ti 3Al 2.5 (Grade 12), and Titanium 15-3-3-3.

What Things To Consider In Titanium Machining Services?

Titanium CNC Machining is a popular process for manufacturing many parts from numerous industries like Medical, Automotive, Marine and Aerospace. Whatever your part is and whichever industry it is a part of, you must consider the following points while doing CNC machining with Titanium –

- There are possibilities of adhesive wear or galling if two parts of Titanium are cold-welded. The machining should be in such a way that seizing up can be avoided of two contact points of the metal.

- You should consider reducing RPM in a CNC machine while working with Titanium. Besides, you can also use a cooling machine as Titanium produces much heat at the contact points while CNC machining.

- As Titanium is rather less flexible compared to other metals and their alloys, you should provide a hard grip on the CNC machine while working with this metal. The automation should be kept running while working on a big scale for maximum benefits.

- The CNC machine parts should be stronger and durable compared to Titanium. Otherwise, it may lead to broken parts.

- The tools should be as sharp as they can be because of the strong nature of this material. Besides, adding a secondary finishing stage can also help you give good polished results.

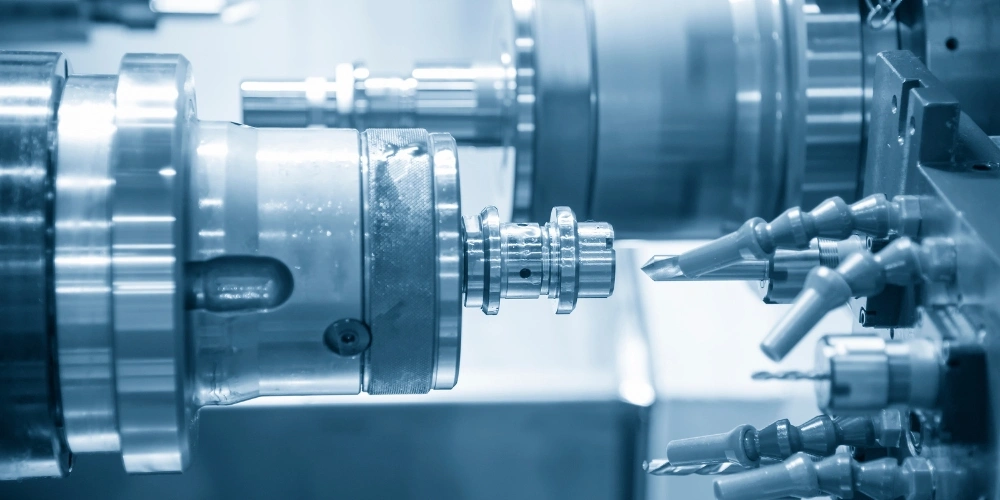

Can You Cut Titanium on a CNC Machine?

Figure 1 –PVD-coated titanium part

Yes, thanks to titanium’s desirable properties, titanium will not give you any type of headache when it comes to machining – not to mention CNC machining, in itself, too. Just like stainless steel, titanium can easily be welded and machined in an inert standard atmosphere.

In addition to this flexibility, titanium can also be bent and bowed multiple times in necessary conditions. So, to help you out with this further, do you know what specific CNC machines are used in processing or machining titanium?

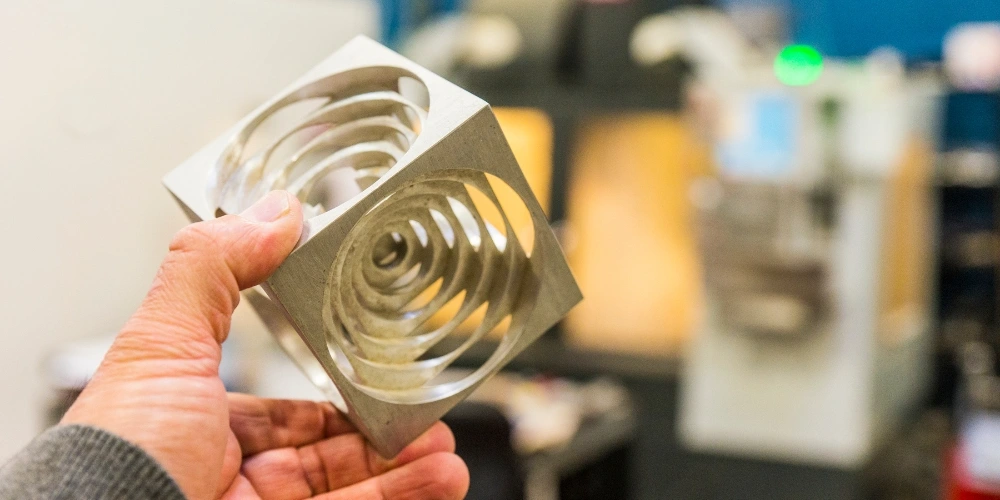

What Material is Used to Machine Titanium?

Figure 2 – A titanium part or component cut by carbide

There is a wide array of materials used for the purpose of cutting, slicing, processing, and machining titanium. However, the most trusted material for machining titanium is none other than carbide.

Being one of the hardest and yet ductile materials in the market, carbide will never fail you when you are looking to machine titanium.

Besides the fact that it has a wide temperature range, it also boasts of a high thermal conductivity, high elasticity modulus, and it would not break down even if subdued to pressure and force – that is tolerable, of course.

Carbide is labelled only as the best in machining titanium. However, apart from carbide, you’ll also be able to find other materials such as ceramics, cast alloys, and even high-speed steel.

NOTE: Some manufacturers also use laser cutting, waterjet cutting, and even plasma cutting machines in slicing and machining titanium!

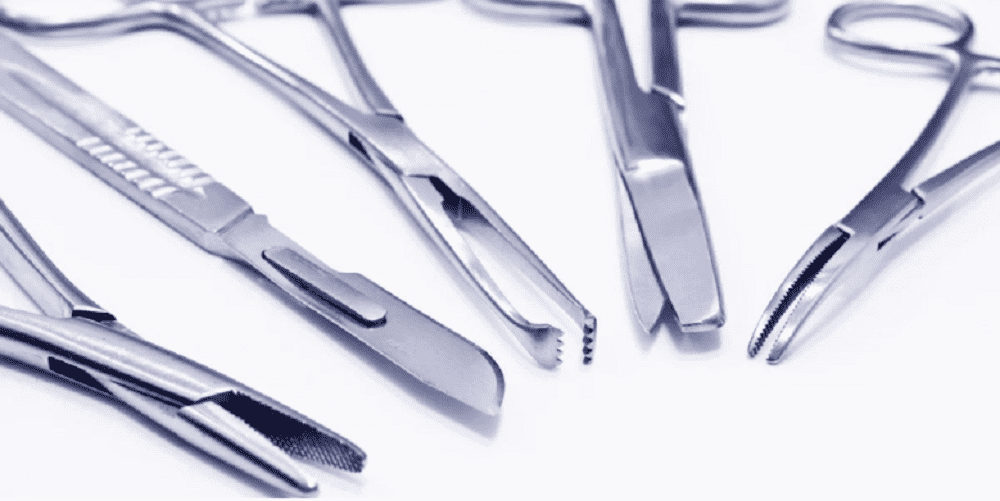

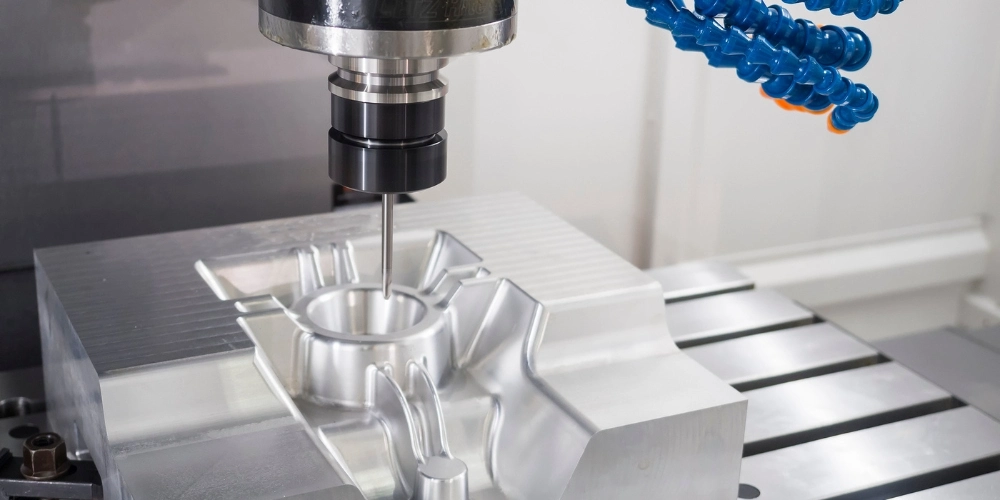

What Titanium Parts and Components Can You CNC Machine?

Figure 3 – Titanium-built turbine blades

There are a lot of titanium parts and components you can find that are actually made via CNC machines. And although the majority of these products would have the subtlest and slightest of differences, you will notice their indifferences especially when it comes to the measurements and overall precision and accuracy of the parts and components.

To name some of the few most common parts and components CNC machines have made in history, here they are:

- Turbine Blades and Engines

- Engine Parts and Components

- Medical Screws and Latches

- Dental and Medical Implants

- Discs and Shafts

- And Many More!

What Grade of Titanium is the Easiest to Machine?

According to expert structural engineers and professional manufacturers, the best and most convenient titanium grade to manufacture is Pure Titanium. The reason for this is because of three (3) major factors:

- They have extremely high flexibility

- The heat conductivity of titanium is low

- Most titanium alloys have high hardness levels

- They are ultimately lightweight, making it easy to machine

Although pure titanium alloys are what many experts consider the easiest and most convenient to machine, we here at HDC Manufacturing choose Titanium Grade 5 for most parts and components that require it.

Besides the fact that it has a relatively low thermal conductivity, it’s also not going to mess and tamper with the overall condition of it because the temperature will be maintained even while it’s being processed or machined.

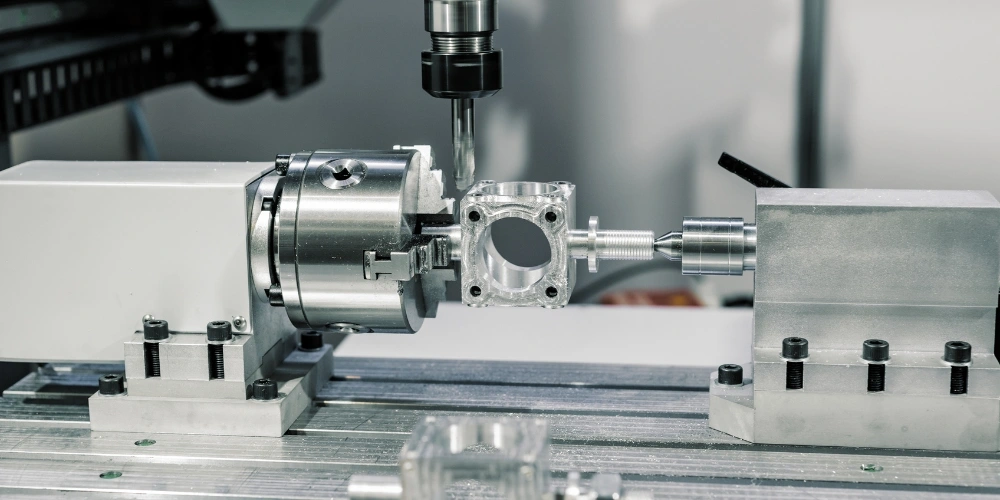

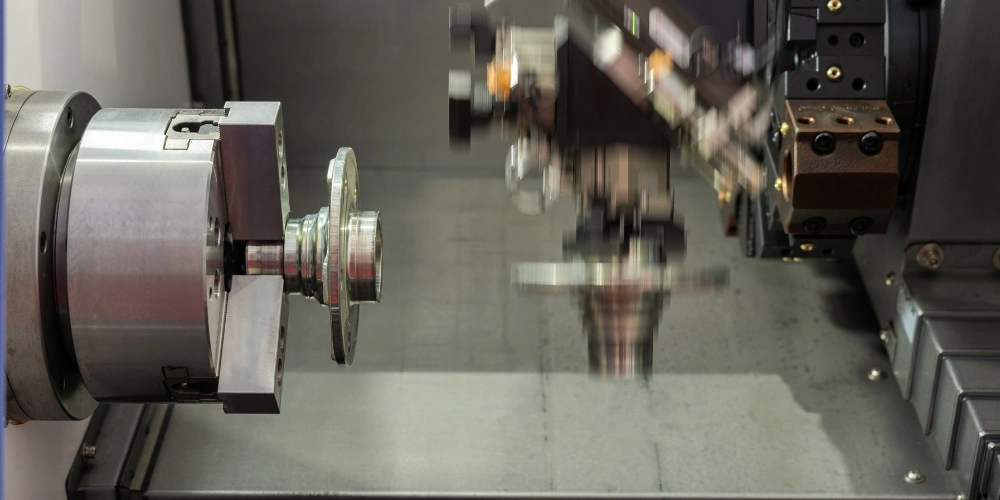

CNC Machining Titanium vs. Stainless Steel

Figure 4 – CNC machined titanium (left); CNC machined stainless steel (right)

Usability-wise, titanium and stainless steel are two (2) very different materials. They’re set on the same foot, and it’s something that needs to be identified by manufacturers as it is an important ingredient in making sure that the parts and components are highly accurate.

We want to make your lives easier, and for that, we’re presenting a table that you can look back to in case you want to check the better material for the current project you are on.

| Titanium | Stainless Steel | |

| Composition | Nitrogen, Oxygen, Carbon, Iron, Nickel, and Hydrogen | Almost the same composition, but they have about 11% more Chromium (also has molybdenum, selenium, nickel, sulphur, etc.) |

| Corrosion Resistance | More corrosion resistant than stainless steel | Corrosion resistant but will come at a time where it can be corroded |

| Thermal Conductivity | Conductivity runs from 118 BTU-in/hr-ft²-°F | Conductivity runs from 69.4 to 238 BTU-in/hr-ft²-°F |

| Electrical Conductivity | Poor electrical conductivity | Poor electrical conductivity, but about 0.4% better than titanium |

| Melting Point | Titanium has a melting point of 3000 to 3040 °F | Stainless Steel has a melting point of 2250 to 2790°F |

| Hardness | Fairly hard in the Brinell scale | Fairly hard in the Brinell scale |

So, in case you have questions and doubts between using stainless steel and titanium in terms of machining, here are the differences they have! Now, you don’t have to guess what’s better for the current project that you are working on!

Why Is Titanium Difficult To Machine?

Many reasons make Titanium a little difficult to work with –

- The formation of Titanium requires much more strength than other materials

- Because of surface oxidation and lower thermal conductivity, the tools cutting the material can lose their edge quite easily

- The swarf of Titanium are flammable and can create problem in case of a fire in the working place

- It has a 40-50% lower elasticity modulus than that of steel and its alloys which can increase uncomfortability to work with it

- Automation is very difficult if you are not working with the right people. A slight difference in the automation process from the recommended one can lead to the jeopardy of your production

How To Achieve High-Speed Titanium Machining?

Because of its properties, Titanium is a good material to work with. But for the same reasons, you may find it difficult to increase the production speed with Titanium machining. But there are certain techniques to increase the speed.

Cutting Tools

Cutting Tools must be chosen according to the properties of Titanium to get the best speed possible. The material used in the cutting tools is the key for high-speed manufacturing. The material in the tool should be –

- Highly resistant to temperature

- They cannot mix with Titanium chemically while the temperature is high

- The strength and durability of the material should be pretty high

- Need good thermal conductivity rate

Turning With Rotary Inserts

This technology has around passing path for the material and cuts the metal without giving it the time to heat up. So, this can be easily used for turning Titanium without having risk of temperature.

Cutting With Ledge Tools

You can use tools that have thin protruding ledges to cut Titanium. Chipping and flanking with these tools can be easy and speedy. The chips are very thin and can be used in many parts’ production. These types of tools were first developed by General Electric.

Ultrasonic Vibration

You can use ultrasonic vibration to remove the extra metal for giving Titanium the shape you desire. If you use ultrasonic vibration to your tools, the process becomes much easier and the force helps to give the cutting tools better longevity.

If you can apply the above-mentioned strategies, then you can surely pace up the speed of titanium machining. Certainly elasticity, temperature and high strength are the three key parts that can meddle with titanium machining. If you can match your tools with these properties, then you can certainly have a high-speed manufacturing process.

Which Grade Of Titanium Is Best For Machining?

Various grades of titanium are available in the market. Titanium alloys are good in strength, ductility, and durability.

Grade 1-4 titanium has hardness 100, 90, 80, and 70 giving them machinability 46%, 40%, 35%, and 28%. These are basically the easiest materials to machine.

When it comes to alloys, almost 50% of all titanium used in machining are of Grade 5 Titanium Ti-6Al-4V, 4906, 4920, 4928. This Alpha-Beta alloy has good properties for machining and manufacturing products for different industries like medical, marine, and aerospace.

Ti-3Al-2.5V, 4943, 4944 are also popular for versatile industries. The alloy has 28% machinability and works quite well even in the medical field.

How To Find The Best Titanium Machining Services Company?

You can find some tips here to help you with finding out the best titanium machining service provider –

Quality Control

Check out the paper trail and numbering regarding the quality control process of the CNC machining provider to find out if their quality control process is up to the mark.

Experience In Titanium

CNC machining is a modern-day cutting-edge technology. You must learn if a service provider has enough experience in titanium as it has many unusual properties to work with.

Minimum Order Quantity

Check out the MOQ of the company. If it has a lower minimum order quantity for titanium products, then it can help you enter the market easily.

Delivery Schedule

You should find out the delivery time required for an order from the company. If their past records show delivery on time has been achieved, then you can proceed.

Customer Care

Customer care services can be measured through communication and quotation achievements. If you go through it, then you can measure easily if they are going to give you comfort in working or not.

If you are satisfied with these points of different CNC machining companies, then you should analyze the market and proceed to a field visit, then you can absolutely understand which is the best one to work with.

Conclusion

Titanium is a popular material nowadays. The parts manufactured with this strong material are ruling many industries, from medical to vehicles and even ornaments and accessories. For lightweight titanium ornaments and watches are even embraced by everyone around you. These are all the reasons you should go for titanium machining for your next project.

Related HDC Titanium Fasteners

HDC takes pride in delivering every component. Our long guaranteed warranty implies that you can feel secured and confident for a long time. HDC will be with you every step of the way in creating your precise titanium bolts.

HDC titanium bolts are made with high grades of titanium that provide more strength and endurance. Our titanium bolts can be customized with your style, size, shape, and color desire.

Why are titanium parts important for your industry?

Titanium parts are considered to be one of the best materials for use in multiple industries. This is because titanium and its alloys possess certain qualities that make the material one of the most loved metallic alloys in certain spheres of the industry. So what are the properties that make titanium parts so special? let’s find out here:

· High tensile strength

Titanium parts have higher tensile strength than a lot of other metallic alloys. So much so, that a few titanium alloys have tensile strength equal to that of low-grade stainless steel. This makes titanium and its alloys a great choice for application in areas where higher tensile strength metal is required.

· Higher-strength to density ratio

One of the greatest properties of titanium is that it has a very high strength-to-weight ratio. This means that titanium parts can provide you the same strength at a much lower weight. As a result, titanium is a very popular material when it comes to saving weight like in Aircraft.

· Low thermal conductivity

Since titanium parts have lower thermal conductivity it is safe to use these parts in areas of heat generation. This includes exhaust areas of cars where the temperature is elevated.

· Resistant against shearing

Unlike a lot of other metals, titanium requires a very sharp cutting tool to be shaped. This means that it is resistant to normal wear and tear that parts experience. This property of titanium makes it a first choice for a lot of application areas.

· Higher modulus of elasticity

Due to the higher modulus of elasticity, titanium is an efficient material for use in the construction of springs. This means that titanium-made products reach the same level of elasticity much earlier than other available options in the industry.

· Corrosion-resistant

Corrosion is one of the major issues that you have to consider while selecting a part. However, titanium has a quick oxidation process which forms a protective layer on the titanium material. Subsequently, the material is protected against corrosion.

These are just a few of the advantages of using titanium parts. Now let’s have a look at which industries make use of titanium as a go-to solution for their industries.

What are the major industries that use titanium parts?

· Aerospace Industry

The aerospace industry widely uses titanium products due to their high strength to density ratio. Titanium parts are often used in aircraft, missiles, rockets, and spacecraft.

· Jewelry

Titanium rings and other such jewelry are very popular nowadays. This is because titanium parts do not corrode with time neither do they deform. Therefore, titanium becomes the first choice for jewelry for all those who do not want to invest in gold and silver.

· Medical Equipment

Upon research, it has been found that the gum metal, i.e. the titanium alloys with Nb, Ta, and Zr have properties similar to that of human bones. As a result, this alloy serves as a perfect solution for the creation of prosthetics. Furthermore, due to its corrosion-resistant properties, the titanium parts are also good choice to make bone screws, that are very homogenous with the human anatomy. In addition to these, there are multiple applications of titanium in the medical industry.

· Marine Industry

Like the aerospace industry, the marine industry also gives a lot of importance to the weight of the parts. Titanium parts in this regard stand out from the rest of the metals as they have higher strength for the same weight as compared to other metals.

· Industrial Machine Parts

In addition to the above applications of titanium parts, a lot of machines in various industries have titanium parts. This also includes nuts, bolts, screws, plates, etc. However, you will find out that titanium products are there in a lot of machines. Thus, you can benefit by having the right information about these parts. And in case you have some difficulty in selecting the right part for your machine, then we will help you in the process.

· Nuts, Bolts, and Consumable Materials

HDC also deals in the manufacturing of Nuts, Bolts, and other titanium parts consumables. These materials are often difficult to find in the market. Even if you are able to secure titanium bolts, nuts, or other consumables there is a long lead-time before the part finally reaches your business. Therefore, we strive to make these parts readily available for you and at a very reasonable cost.

What capabilities HDC has to transform your Titanium Parts?

Naturally, your next question will be that what HDC can provide you with in order to transform your titanium parts? Well, let’s walk you through this part too.

We at HDC are an experienced group that knows what to do with titanium in order to make it perfect for your machine.

With our state-of-the-art CNC machining facility, we develop titanium parts that are made for fit. It means that you will not have to worry about fitting our parts into the machines and they will exactly fit. A few of the benefits that you will get in working with HDC are as follows:

· High-quality parts

One thing is for sure, you will not have to complain about the quality of our products. We take pride in our expertise and experience when it comes to machining titanium parts. And we will never compromise on the quality of titanium products. Also, the machines that we use in the manufacturing process are of high precision and will manufacture parts to perfection.

· Machined to perfection

Our state-of-the-art machining facility will create the parts you need to point to perfection. You will not have to worry about the size misfits or differences with your requirements at all. Since we believe in customer satisfaction, we believe it to be our duty to develop parts that you will love to use.

· Customizable parts

One of the biggest challenges that industries face today is the provision of customized parts as per the specifications provided by the industries. However, HDC excels in this domain. We will provide you with customized titanium parts that will be as per your required specifications.

· Reliability

We ensure that you will get the highest reliability of parts. So that your machines or parts do not fail over time. In order to ensure that you have got the highest reliability of titanium parts, we have regular quality assurance checks. Furthermore, our company is ISO 90001 certified. This means that all you will have to do is give us the order and then forget worrying about the product.

· Experienced team

Perhaps one of the things that we take pride in is our experienced team. We have a team of veterans in the field of industrial parts and machining of titanium parts. And that is why we exactly know what you need even before you have told us about your requirements. Well, if you don’t believe us, then talk to us and we will let you know why we say so.

How will your business benefit from working with HDC machines?

Your business requires high-quality, durable, and reliable parts for smooth functioning. We on the other hand are providing these titanium parts as per your requirements. In order to ensure that you get exactly what you have ordered, we have a pre-order sample check for our clients. This means that we will give you a sample piece to give you an idea of the quality and specification of the product. In case you will like the product, which we are sure you will, then we will proceed with the manufacturing of the rest of the lot.

In addition to exclusive customer care, we are more than willing to work closely with you in making your project a success. Here is how your business will benefit from working with us:

· Parts as per your specifications

One of the most important things that we consider is that our clients’ products should be as per the requirements provided to us. In order to make sure that you get what you have ordered, our experienced team of professionals stays in close touch with our clients. This means that you will get what you have ordered and you will not have any issues in installing titanium parts received from our side.

· Timely delivery

Another benefit that your business will incur in working with us is that you will get timely deliveries. This is a major benefit for businesses as lead times for parts create a lot of issues for businesses. However, due to our dedicated supply chain team, you will not have to face any delays on your shipments and you will get the titanium products on time.

· Higher reliability means higher productivity

Once you know that you have a high-quality part installed in your machine then you will not have to worry about the machines’ reliability. Therefore, you will be able to work with more confidence and the productivity of your business will increase manifolds. And you understand that higher productivity means a direct increase in your sales and profits.

· Availability of spares will reduce downtime

Lead times are a major issue when it comes to the availability of titanium parts. Therefore, if you have a local manufacturer who can provide these products to you in the shortest possible time is always an advantage. Furthermore, for our international clients too, we ensure that the parts reach them on time. As a result of this, our clients will have spare parts in their inventory at all times, resulting in lower waiting times for the restoration of machines.

· Value for Money

One of the greatest benefits that you will accrue in working with HDC is that you will get value for each ounce you spend. With our experienced professionals, we have devised special methods that reduce the amount spent on the manufacturing of titanium parts. Furthermore, with the high-quality finish products, you will always find that your money is well spent. Moreover, we have quite competitive rates when it comes to the titanium parts market. You can check out by getting a quote for further details on the rates that we offer.

What will be the packaging and shipping details?

A lot depends on the product that you want shipping for. However, you can find a pictorial explanation here for your information. Generally, we pack all the products as per the international standards. We have proper bubble film, EPE wrap, and all other packaging techniques. Furthermore, the outer box is decided based on the material inside. In case it is a heavy or valuable part then it is packed in a carbon/wooden box. However, if it is a lighter titanium product then the product is packed in a cardboard box before being put into the carton. You will get your product safe, this is our guarantee.

For shipping, we have a separate team that ensures that the material safely leaves our factory and is delivered to your doorstep. Therefore, you will not have to worry about any shipment details. We have it all covered. However, the lead time for each country may vary due to the different customs rules and procedures in place.

Please contact us to exactly know the lead time and delivery details for your country.

What will be the after-sales procedures?

The aftersales process is often the most cumbersome of all. However, with an experienced team like ours, we enjoy providing support after the sales have been made. This is because we believe in satisfying our customers and making them come again and again to us because of our great customer care. In case you have any issues with the delivery or that you think you have not received what you had ordered then we are available to solve your problems. You can contact us through email, phone, or skype. And we will be available to resolve your issue.

Since a lot of our customers are international customers, we make sure that time-zone difference does not hamper our seamless customer care. So, no matter which part of the world you are from, we will be there waiting for your issues and resolving them.