Stainless Steel Advantages and Challenges

Have you ever heard of what Hastelloy X is? Do you know the run-ins and information about this super alloy? If you answered yes to those questions, then, don’t fret, because we got you!

For more than a decade, we here at HDC have been one of the manufacturers focused in many alloys, even in these types of super alloys, too. So, if you’re in the market and you’re looking to learn more about Hastelloy, this blog is for you!

What is Hastelloy X Material?

Source: Ganpat Industrial

I know you think it came out of a superhero movie or not a lot of people actually know about. But no, Hastelloy X is actually one of the few superalloys in existence renowned for its strength, durability, and temperature resistance.

Hastelloy X is a wrought, nickel-based alloy that’s loved because of its stress-corrosion cracking resistance.

NOTE: Superalloys, in case you didn’t know, possess excellent creep and oxidation resistance. Moreover, you can strengthen them even further using different hardening methods.

Hastelloy X Mechanical Properties and Characteristics

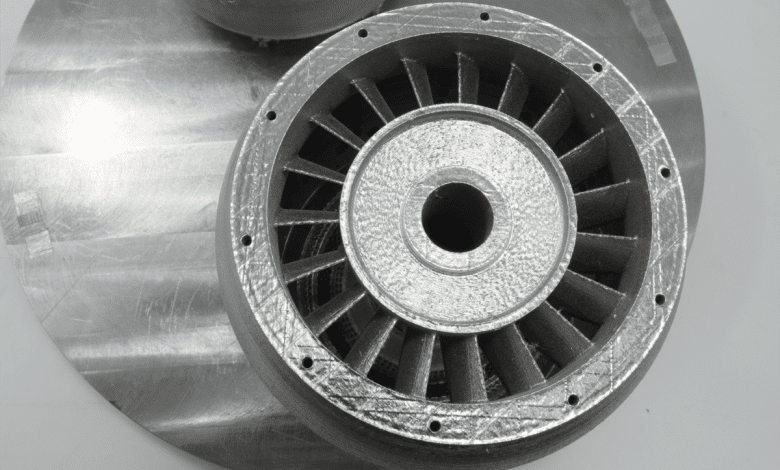

Source: Voxel Matters

For many people, the alloy may still come as a surprise because of its overall uniqueness. From the name to what it is, it’s not something you’ve heard of in the fundamentals of the industry.

So, to further your familiarity with it, let us talk about Hastelloy X alloy’s properties and characteristics.

Hastelloy X Chemical Composition

One of the most important things to know when it comes to these types of superalloys is their composition. By understanding what they’re made of, you’ll have a clearer sense of what the alloy is capable of.

Hastelloy X’s composition is outlined in the table below:

| Element | Content (%) |

| Cr, Chromium | 20.5-23 |

| Fe, Iron | 17-20 |

| Mo, Molybdenum | 8-10 |

| Mn, Manganese | 1 max |

| Si, Silicon | 1 max |

| Ti, Titanium | 0.15 max |

| Co, Cobalt | 0.5-2.5 |

| Al, Aluminum | 0.5 max |

| Cu, Copper | 0.5 max |

| C, Carbon | 0.05-0.15 |

| P, Phosphorus | 0.04 max |

| S, Sulfur | 0.03 max |

| W, Tungsten | 0.2-1 |

| B, Boron | 0.008 max |

| Ni, Nickel | Remainder |

These are the different elements making up Hastelloy X. All these have their roles in making sure the product is strong, tough, and up to the manufacturer’s standards.

Hardness

In its solution heat-treated state, Hastelloy X exhibits a Rockwell B hardness of approximately 87, indicating a balance between hardness and ductility.

However, you can increase the hardness if you let it go through different hardening methods, such as solid-solution hardening, precipitation hardening, and work hardening.

Strength

When it comes to strength, Hastelloy X is one of the best and most unbeatable. It maintains excellent and impressive strength across a wide temperature range.

At room temperature, it has an ultimate tensile strength of about 110.2 ksi (760 MPa). Even at elevated temperatures, such as 1000°F (538°C), it retains a tensile strength of 87.6 ksi (604 MPa).

Yield Strength

The yield strength of the Hastelloy X superalloy at room temperature is approximately 49.3 ksi (340 MPa), ensuring it can withstand significant stress before undergoing permanent deformation.

At 1000°F (538°C), however, the yield strength remains robust at 32.5 ksi (224 MPa)

Tensile Strength

Hastelloy X demonstrates high tensile strength, with room temperature measurements around 110.2 ksi (760 MPa). This strength is maintained at elevated temperatures, making it suitable for demanding environments.

Melting Point

Out of the many factors and characteristics of alloys, the melting point is often part of the most important. Since metals and alloys are often worked under certain temperatures, it is vital to know the temperature in which they’ll change and melt.

The alloy has a melting range between 2300°F and 2470°F (1260°C to 1355°C), allowing it to perform reliably in high-heat conditions without compromising structural integrity.

Temperature Resistance

Hastelloy X excels in high-temperature environments, offering oxidation resistance up to 2200°F (1204°C).

Its strength and stability at these temperatures make it ideal for components in gas turbines and industrial furnaces.

Density

And last but most definitely not least is density. Hastelloy boasts a density of 0.297 lb/in³ (8.22 g/cm³), which provides a substantial material mass, contributing to its durability and performance under stress.

Looking at it, overall, Hastelloy X is an excellent superaloy that’s craved because of its strength and its ability to resist chemical and physical deformations.

What is the Equivalent of Hastelloy X?

Source: Petro Tube

The known and common equivalent alloys of Hastelloy X include Inconel HX, Werkstoff Nr. 2.4665, and UNS N06002. These aso are nickel-chromium-iron-molybdenum-based.

Getting Your Hastelloy X From HDC

At HDC, we often capitalize on our skill and ability in machining and fabrication. However, that’s not everything we’re good at. For years, we’ve also been trusted by businesses with the quality of our products; from stainless steels, standard alloys, and super alloys, we can help you.

So if you’re looking for custom high-quality metal or plastic parts and components, don’t hesitate to contact us. We do business and ship worldwide, so, we’ll get you what you need wherever you are!

Contact us today and get a free estimate of your orders without locking into a contract!

Discover more with our blog posts.

Recent Posts

Discover more about our products

HDC Products

Instant Quote!