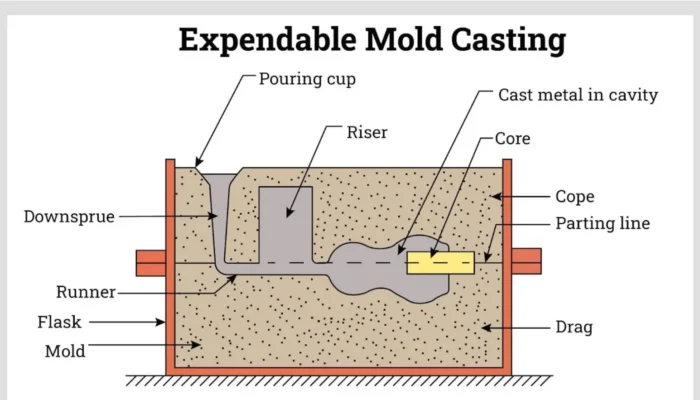

Expendable Casting

When you are producing metal parts, you require casting techniques that offer you doubt and precision and the ability to control costs. That you get as a result of the expendable casting process. One way of doing this is by making a mold, pouring molten metal into it, letting it cool, and then destroying the […]