Aluminum Alloys come in all sizes and shapes. However, a few of the most common types of Aluminum Alloys are Aluminum 6061 and Aluminum 6063. In this article, we will provide a comprehensive analysis of the features, strengths, and weaknesses of each of these Aluminum Alloys, and help you decide which one to use for your application.

Overview of Aluminum Alloys 6061 and 6063

Aluminum 6061

Aluminum 6061 has excellent mechanical strength and corrosion resistance, as it is a precipitation-hardened alloy. Due to its strength-to-weight ratio and other properties, it is widely used in a number of industries. Here are a few basic characteristics of Aluminum 6061:

Physical Properties of Aluminum 6061

- High Strength and Hardness: Aluminum 6061 provides exceptional strength and hardness, making it suitable for heavy-duty applications like structural components and load-bearing supports.

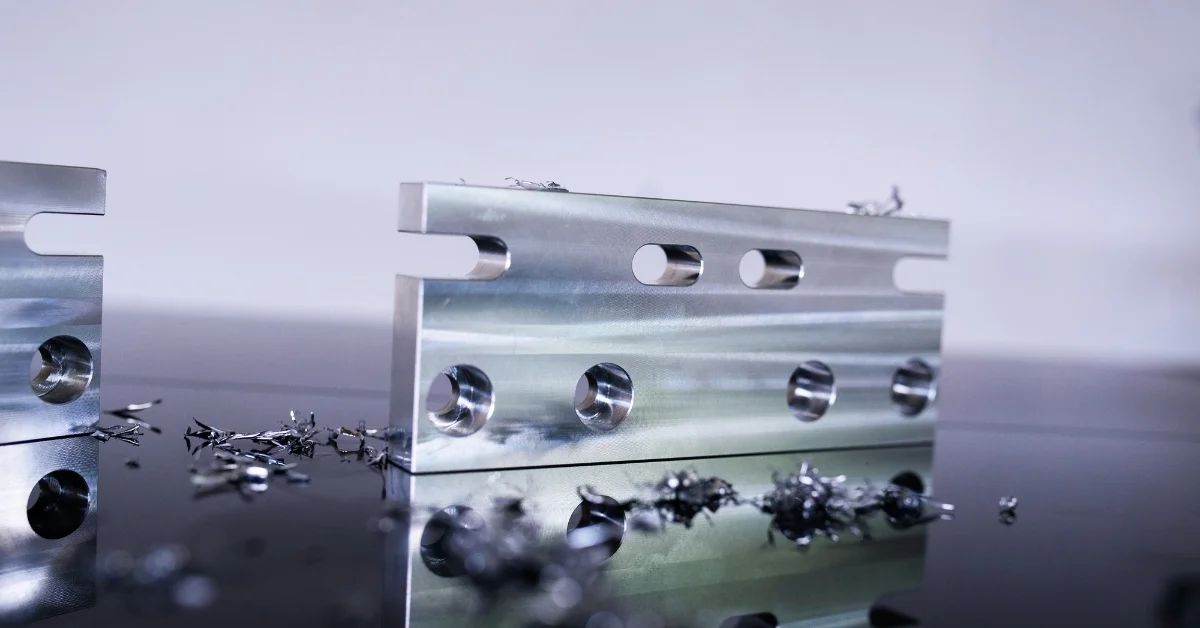

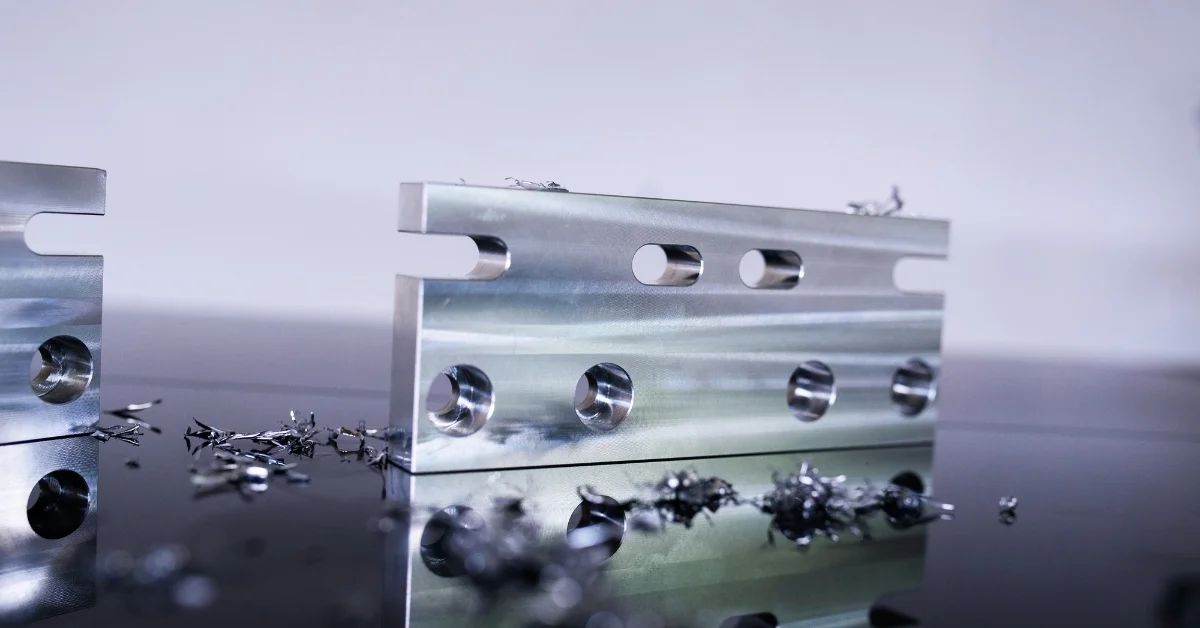

- Higher Options for Machinability: Known for its excellent machinability, 6061 can handle precision machining with tight tolerances, ensuring superior performance in industrial and automotive parts.

- Superior Resistance to Corrosion: While it offers good corrosion resistance, additional anodizing enhances its performance in harsh environments, including marine or chemical exposure.

- Easy to Weld: Aluminum 6061 is highly weldable, with post-weld heat treatments available to restore strength in welded areas for structural integrity.

- Strengthened in T6 Temper: The T6 temper increases the material’s strength and durability through precipitation hardening, making it ideal for demanding applications.

Chemical Properties of Aluminum 6061

Aluminum 6061 contains traces of magnesium (0.8–1.2%) and silicon (0.4–0.8%). It also includes iron, copper, chromium, zinc, and titanium.

Aluminum 6063

In contrast to Aluminum 6061, the 6063 alloy is ideal for applications where aesthetic appeal is a priority. The strength of Aluminum 6063 is slightly lower than 6061; however, it compensates for the lack of strength with its surface finish and resistance to corrosion.

Physical Properties of Aluminum 6063

- Medium Strength: Aluminum 6063 has moderate strength compared to 6061, making it ideal for applications where aesthetics and lightweight characteristics are more critical than heavy-duty performance.

- Exceptional Resistance to Corrosion: Naturally resistant to corrosion, 6063 performs well in marine and outdoor environments without requiring additional treatments.

- Superior Extrudability for Complex Designs: With outstanding extrudability, 6063 allows for intricate profiles and designs, making it a top choice for architectural and decorative elements.

- High-Quality Surface Finish: This alloy is known for its smooth and attractive surface, which is ideal for visible applications like window frames, door trims, and decorative parts.

- Balanced Properties in T5 Temper: The T5 temper provides a good balance of strength and corrosion resistance, optimizing its use in medium-load applications with excellent durability.

Chemical Properties of Aluminum 6063

Aluminum 6063 contains magnesium (0.45–0.9%) and silicon (0.2–0.6%). Similar to Aluminum 6061, it also has traces of iron, copper, manganese, and zinc.

Comparing the Aluminum 6061 vs. 6063 Mechanical Properties

| Property | 6061 Aluminum (T6) | 6063 Aluminum (T5) |

| Yield Stress | 40,000 psi | 27,000 psi |

| Strength | Higher, suitable for load-bearing applications | Lower, suitable for aesthetic applications |

| Hardness | Brinell hardness of 95 | Brinell hardness of 73 |

| Wear Resistance | Better suited for resistance to wear and deformation | Less resistant to wear, softer composition |

| Machinability | Excellent; allows for tight tolerances | Good but softer; prone to deformation |

| Corrosion Resistance | Good; may require anodizing in harsh environments | Superior natural resistance, ideal for marine environments |

Applications of Aluminum 6061 and 6063

Industrial Applications of Aluminum 6061

Aluminum 6061, due to its higher strength and durability, is widely used in industries requiring a good strength-to-weight ratio. Here are a few examples of the industrial applications of Aluminum 6061:

- Aerospace Components: The aerospace industry requires highly durable materials without affecting the weight or payload of the aircraft. Aluminum 6061 offers the best trade-off and is widely used for manufacturing, airframe parts, hydraulic systems and fuel tank structures.

- Structural Beams and Supports: With the increase in the design complexity of building structures, Aluminum 6061 is ideal for bearing the strength of heavy weights in bridge fixtures, load-bearing beams and scaffolding applications in the manufacturing industry.

- Automotive Parts: Similar to aerospace, automotive parts need to be durable yet lightweight. Aluminum 6061 is used for truck frames, boat hulls and bicycle frames.

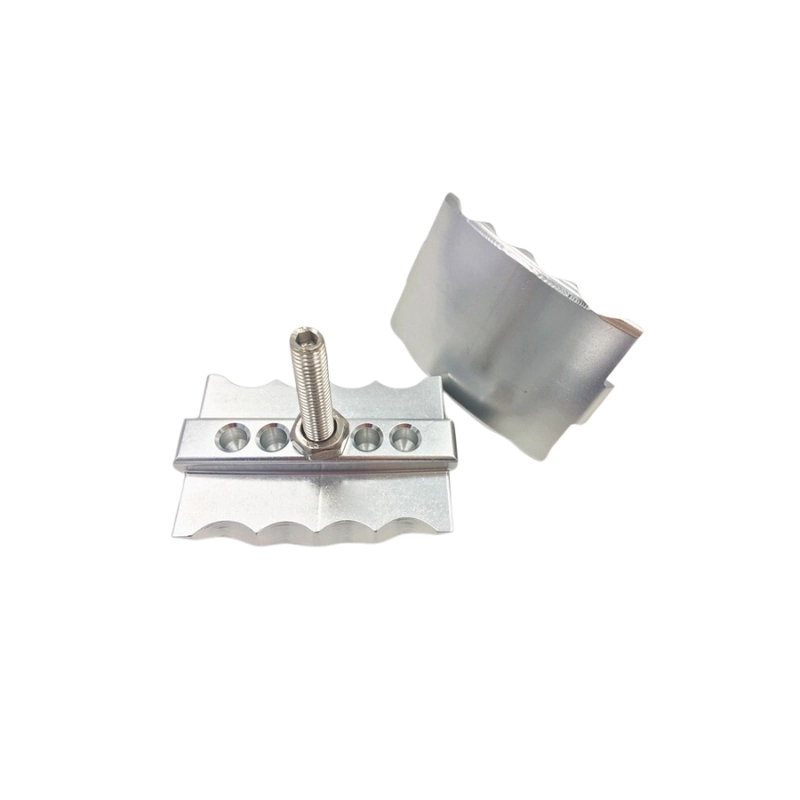

- Machinery and Industrial Equipment: The high durability of 6061 makes it ideal for development of industrial jigs and fixtures, robotic and automation parts, and precision-machined components.

6063

The 6063 aluminum alloy offers a lot of value through its beauty and elegance without affecting the corrosion resistance of the alloy. Therefore, it is used across a number of industries.

- Architectural Elements: The beauty and finesse of Aluminum 6063 make it a popular choice for manufacturing window frames and doors, curtain walls, and other decorative trims.

- Piping and Tubing: Due to its high corrosion resistance, 6063 aluminum is often used in development of irrigation system pipes, light structural tubing and other types of railings and fences

- Heat Exchange Systems: 6063 is a top choice for manufacturing heat exchange jackets like heat sinks and radiators.

- Furniture and Lightweight Frames: Due to its lightweight properties and aesthetic appeal, 6063 aluminum is commonly used in manufacturing of furniture frames, frames for sports equipment and frames for ladders.

- Marine Applications: In the marine industry, alloy 6063 is ideal for manufacturing of boat rails and masts and other enclosures that are corrosion-resistant.

How to Select the Right Alloy for Your Application

- What is the required strength?

- For high-strength applications, like construction or structural loads, 6061 aluminum is the better choice.

- For less load-bearing applications, 6063 aluminum works well.

- Corrosion Resistance Offered?

- 6063 aluminum offers better corrosion resistance in moisture-based environments.

- 6061 aluminumcan be anodized to enhance its corrosion resistance.

- Level of Machining Requirement?

- For precision machining or applications with tight tolerances, 6061 aluminumis superior.

- Cost Impact?

- While 6061 aluminum priceis higher, its strength and versatility make up for the cost.

- 6063 aluminum price per pound is more economical for aesthetic or lightweight applications.

- Surface Finish Required?

- For a smoother surface finish or more complex designs, 6063 aluminum is the ideal choice.

Conclusion: Aluminum 6061 or 6063 – Which is Ideal?

Summing up, it is difficult to declare any one of the alloys to be a clear champion since each of the alloy has differing pros and cons. Therefore, 6061 aluminum properties make it an ideal choice for heavy-duty applications. Whereas, if you have focus on aesthetics, a need for corrosion resistance and extrudability, 6063 aluminum alloy is the best choice. In view of the differing pros and cons offered by each of the aluminum alloy, choose the alloy that best meets your application requirements.

Discover more with our blog posts.

Recent Posts

Discover more about our products.

Related Products

Instant Quote!