Enhancing Engine Performance with Precision CNC Valve Covers

Delve into the world of CNC valve covers, a crucial component in enhancing engine performance and aesthetics. Learn about the functions, benefits, materials used, and the customization options available for these precision-engineered covers.

Understanding CNC Valve Cover

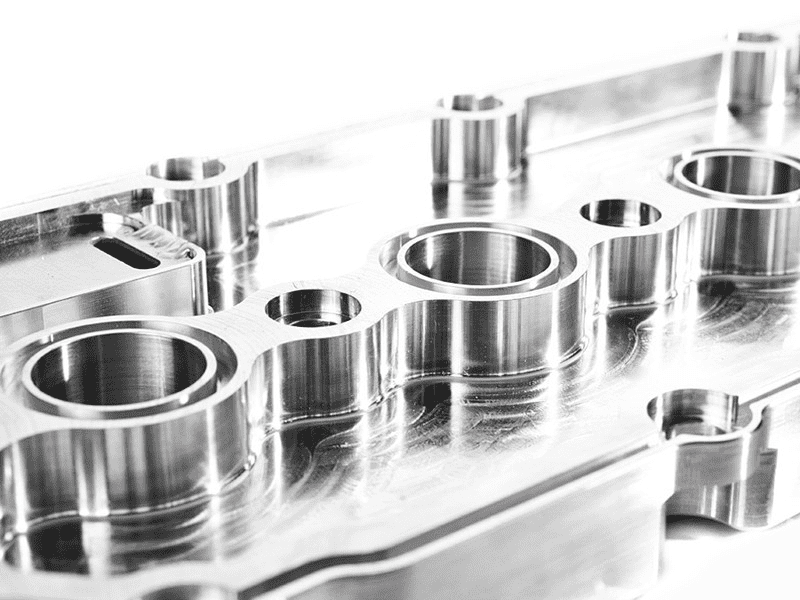

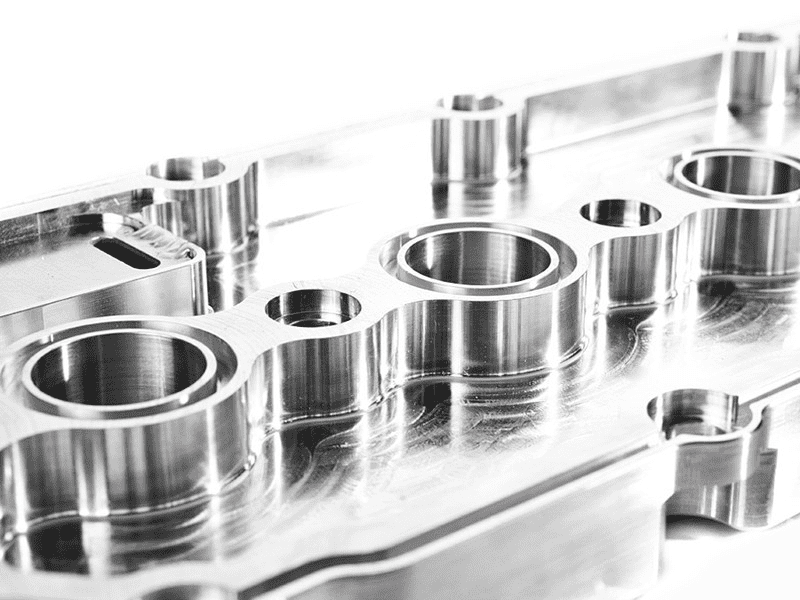

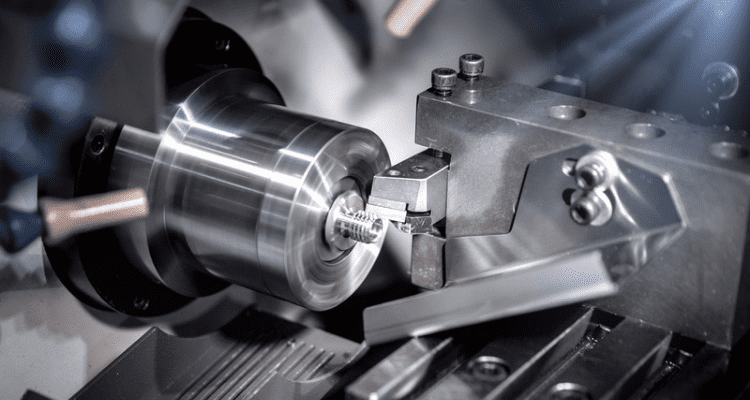

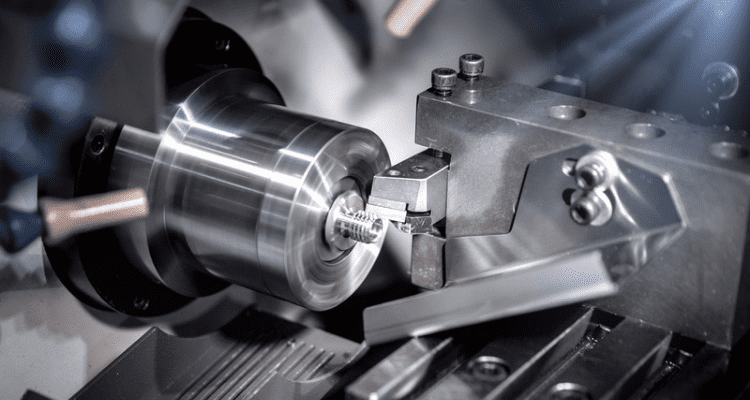

A CNC valve cover is an Engine valve cover customized with CNC machining. CNC machining valve covers can be of custom designs and usually heavier than normal valve covers. They have even better durability than the original ones. Even because of CNC machining, the custom valve covers look better.

The Functions Of A CNC Valve Cover

CNC valve covers are specially made valve covers by CNC machining and can give better comfortability. CNC machining valve covers have better durability and can keep your engine parts secured from oil dripping out.

Besides, a CNC machining valve cover protects the oil and circulates back inside so that the engine parts stay lubricated. Oil goes through parts of the engines so that the parts do not get dried and creates problems.

When a valve cover is not okay, you may find out oil smells or burnt oil smells all over your car.

If a situation like this occurs, then you may need to change the valve cover.

As the valve cover protects the valve train, you can stay relaxed with the car lubrication and carry on driving in full swing.

Benefits of Customs CNC Valve Cover

- Put your personal choice over the factory-made uniform covers.

- If you are great at designing car parts and want to show customization.

- If you are looking for a company and want to put your logo and slogan on valve covers.

- If you want certain features on valve covers like billet steel valve covers or even color on your valve cover, that is possible with CNC machining.

Materials Used To Custom CNC Valve Cover

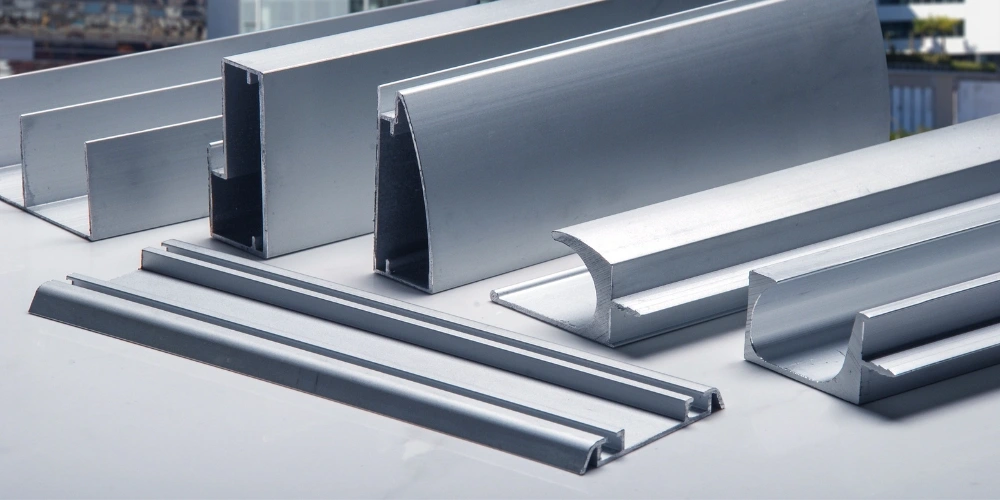

In the past, all valve covers were made of stamped steel. Those are economically effective and materials were available all over. But due to the inferior designs, they showed difficulties to work with. Even when tightened too much, they had the possibility of leaking oil. As a result, the point of using a valve cover went wasted.

As time go on, CNC machining and customization came to the aftermarket and many kinds of materials came forth with better promises than stamped steel.

Finishes Used for Custom CNC Valve Cover

CNC block guards plays a key role in the safety of the engine more so under harsh conditions. Manufactured to perfection with the use of CNC milling, these units strengthen the top wall of the engine thus preventing crack formation. Durability is improved by using aluminium alloys, anodizing or powder coating. They do not only protect engines but also increase power and efficiency by controlling heat. When you want custom CNC block guards, investigate manufactures, emphasize quality considerations and make certain communication is clear. In summary, the CNC block guards are essential for engine protection and operation efficiency which makes it a good choice for harsh conditions.

Fabricated Valve Covers

- You can have them made of matching colors to your engine

- You can have them customized according to your necessary height

- You can put chassis restrictions according to the notches you want

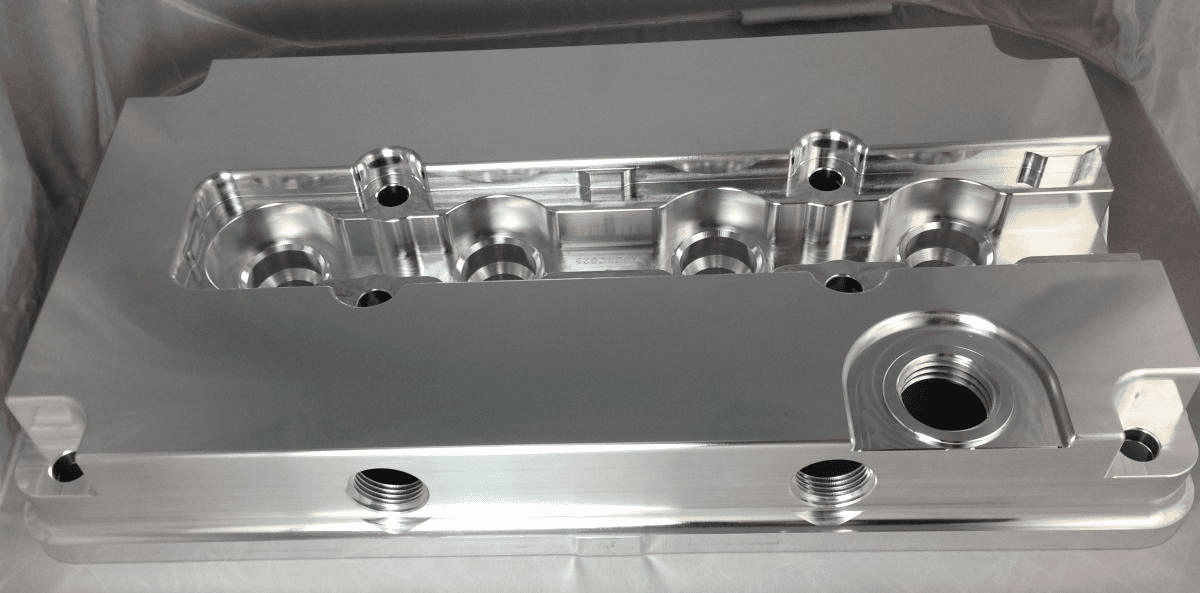

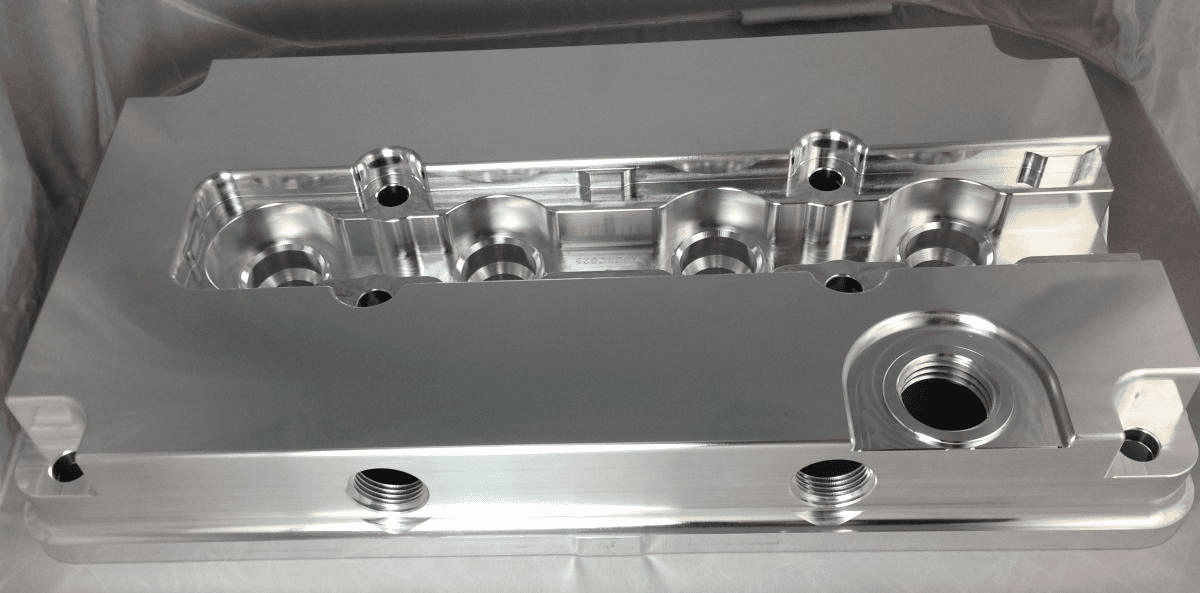

Billet Valve Covers

Billet valve covers are made out of billets. Billets are raw and furnished bars made out of metal. Billets have good-looking furnishing and are quite easy to work with. CNC machining billet steel and billet aluminum are always being used to create valve covers. Valve covers made out of billets have attractive exteriors that can mesmerize car lovers.

Billets are more expensive than stamped steel. Because at CNC machining, you may get 3-4 pounds of steel left in the cover while you have worked with a 60-pound billet bar.

Covers made out of billets have far more durability than other billet covers, for their looks, they are popular among all car lovers.

The Impact of CNC Valve Covers on Automotive Performance

- Helps to keep the oil in the engine in check.

- Does not let excessive oil use for you

- Keeps the interior of the engine intact

- Helps to keep all the parts lubricated for better performance

- Give your car a better look

- Can have better durability

- Can be customized with your logo and slogan

- Can be customized at height and any other point if you think better fit your car

Impact of Replacing Valve Covers on the Engine

- If it leaks oil, then the lubrication of your car parts will not be as usual. As a result, some parts may show unusual problems.

- The interior of the engine may get demolished due to extra leakage of the oil.

- You have to use extra oil which can be very expensive.

- If you do not replace it even after the leakage is known for a few days, the car may lose overall performance for less lubrication on the parts.

Cost Consideration When Custom Valve Covers

In considering the cost of custom valve covers, number of factors play a role. They are the kind of materials used, design complexity, surface finish and the manufacturer’s price structure. Complex designs with high-quality materials just like leather may increase the cost while simpler designs that can be made from aluminum are more cost effective. Other custom elements that add to the price include anodizing or powder coating. Moreover, the number of valve covers that have been ordered also determines the unit cost as larger quantities can get discounts. It is important that individuals invest in custom valve covers for their engines to find balance between cost and the returns of investing it on them.

Guidance of Custom Valve Covers From Manufacturers

When purchasing custom-made valve covers from the manufacturers, you need to follow a systematic process in order to get the required elements. Start by outlining your needs in terms of construction materials, design standards and the level of customization you want. Carry out extensive research to find reliable manufacturers who have successfully made custom valve covers. Send out requests for more detailed price quotes from several manufactures and submit comprehensive specs in order to receive accurate quotes. Work closely with the selected manufacturer to perfect the design and ensure that they are equipped with CNC machining facilities.

Ask them to evaluate their quality assurance processes, talk about lead times and ask for samples for approvals prior to sealing the terms. Keep the communication going throughout production and conduct a rigorous quality assurance when receiving the custom valve covers. By doing so, you will guarantee the cooperation with manufacturers goes well and your custom valve cover project runs according to plan while also achieving an optimal balance between cost versus quality.

Conclusion

Aftermarket custom valve covers not only look good but can have more durability and help to regain the old performance of your engine. Every custom valve cover has its own efficiency according to the need of the engine. Valve covers sometimes look unnecessary for the engine, but the truth is, without them, you may lose the good performance of your car.

Resources: