Explore CNC Shift Knobs for Superior Car Performance and Style

Explore the world of CNC shift knobs and discover how they can transform your driving experience. This guide delves into the benefits of CNC machining for shift knobs, including improved aesthetics, smoother gear shifting, and enhanced durability. Learn why a CNC shift knob is a perfect upgrade for any car enthusiast looking to customize their vehicle's interior.

Understanding CNC Shift Knob

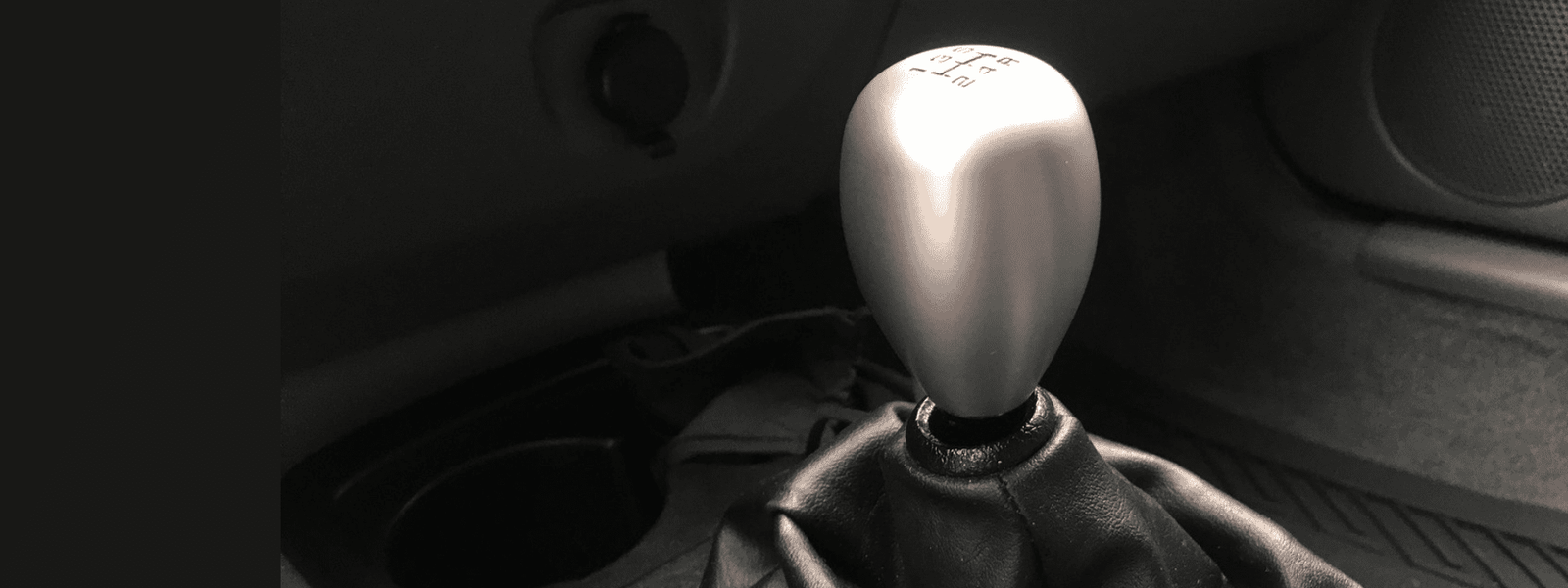

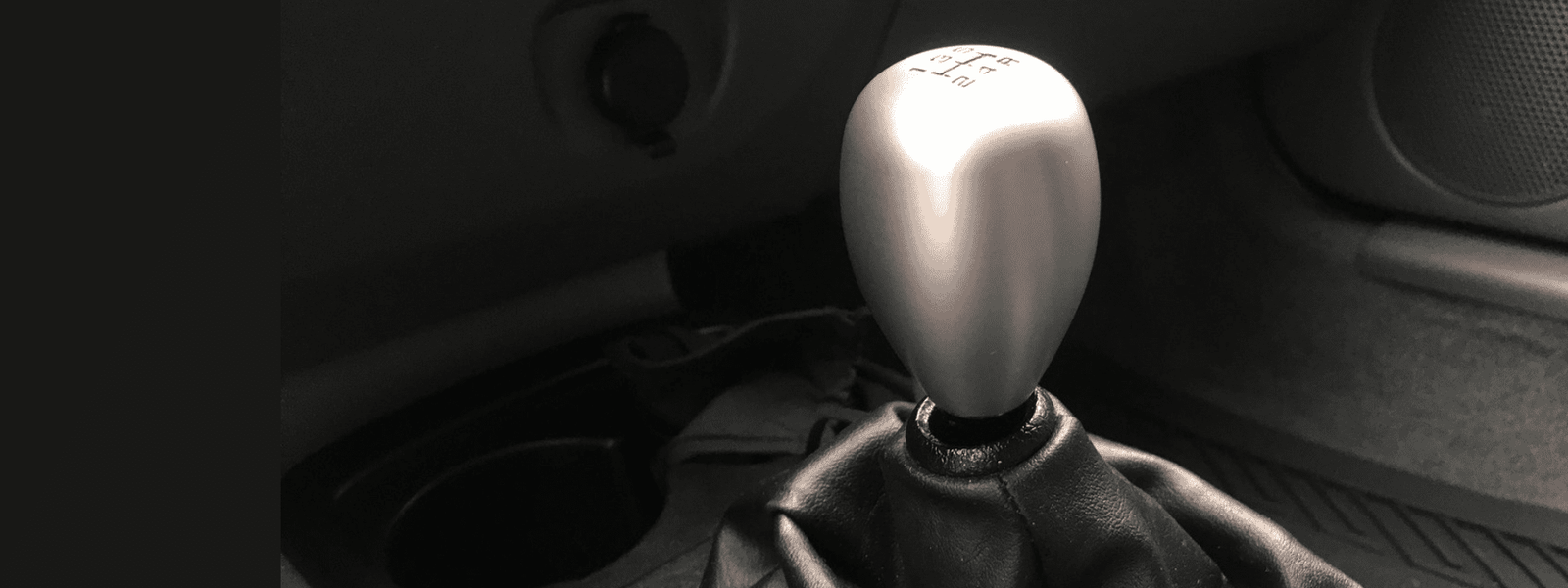

A shift knob is also known as a gear lever or gear shift. It is a metal lever that is attached to the shift assembly of an automotive. In automatic transmission automobiles, a shift knob is a knob that sets on top of the leaver and allows the driver to change gears.

A CNC shift knob is an upgraded version of previous regular shift knobs. Instead of manual machines, CNC machines manufacture CNC shift knobs. Computer programs fully control a CNC machine, and these machines can manufacture shift knobs without any human interaction.

Therefore, CNC shift knobs are perfect in terms of finishing and functionality. They bring different aesthetics to your car and make the gear-changing operations smoother.

You can change your existing regular shift knob and add CNC shift knobs to your car easily. The most exciting part of the CNC shift knob is choosing any design and color, and CNC machines can manufacture the exact shift knob with a tolerance of +/- .01mm.

Benefits Of a CNC Shift Knob

A CNC shift knob is not only attractive but also brings many other benefits. Here are some of the benefits of a CNC shift knob:

Boosts Aesthetics

The typical shift knob that comes with your car is okay and can do the job moderately. But if you want to personify the interior of your vehicle, a cool-looking CNC shift knob is the best way to start that.

Incorporating a CNC shift knob to your will change the aesthetics of the driving zone of your car by a great deal.

Smoother Gear Shifting

Changing gears with your regular built-in shift knobs can be tiresome. With a CNC shift knob changing the gear is easier. Your driving experience will certainly change if you add a CNC shift knob to your car.

Better Grip

Standard shift knobs are not tailor-made. They are made for every person who will use the car. But With CNC machining, you can make a shift knob that perfectly matches your grip.

CNC machines are best known for their ability to manufacture products with nearly zero tolerance. With a CNC shift knob, you will be able to apply the exact amount of pressure you want to imply with a 100% accurate grip.

More Durability

CNC shift knobs are made with durable materials such as aluminum alloy. Consequently, those shift knobs ensure years of service. When the shift knobs last long, you don’t need to purchase another one, right? In that case, you also save money.

Endless Customization

With CNC machining technology, you get endless possibilities. That is one of the significant factors why people tend to use the CNC shift knob. You can design your shift knob and tell the CNC shift knob manufacturer to create that for you.

CNC programs execute the design of a CNC designer. If the designer can replicate your idea, you can get any shift knob from efficient CNC machining technology.

Choose a CNC Shift Knob

A CNC shift knob is beneficial in many terms, but you have to pick the right one that fits your car and requirement.

Fitment

This is the most crucial factor before choosing your CNC shift knob. Even though most manufacturers say that most of their shift knobs are universal, there is still a catch. After all, the CNC shift knob needs to thread at the top of your car’s shifter.

We recommend using an adapter to accommodate other fitments, but you should always double-check to ensure that this is perfect for your automotive.

Some actual universal CNC knobs don’t need to thread on your shifter. Instead, those CNC knobs use screws to tighten your shifter. But over time and with lots of use, these screws can loosen, and the shift knob can pop off.

Type of Material

After fitment, this is the second most crucial thing you should consider before you choose your CNC shift knob. When looking at the material, don’t just go for strength and durability. It would help if you also considered the environment you will drive your car in.

Types of materials define the durability and for how long the shift knob will stay the same.

If you live in a frigid cold or intense heat, you should avoid any metal knob. Whey? Because it can feel very uncomfortable to touch a too hot or icy cold metal shift knob.

Weight

Weight is another vital factor in choosing a CNC shift knob. You will see some shift knobs are heavy, and some others are light. A driver’s personal choice is vital in this case. Some prefer light-shift knobs, and some prefer heavy.

From a technical point of view, a heavy CNC shift knob makes shifting precise and smoother. The weight helps the driver to change the gear adding its weight to the driver’s push. But, if you are not sure about that, we recommend testing both heavy and light and then selecting one.

The Reasons for the Higher Cost of CNC Shift Knobs

Heavyweight CNC shift knobs are made of aluminum alloy and stainless steel. Light CNC shifts are made of wood and sometimes carbon fiber.

Aluminum alloy and stainless steel both are expensive materials. Top-quality aluminum alloys are very expensive materials. Again CNC machining is a complicated process. There are several steps involved in the manufacturing process of CNC shift knobs.

From the design to final production, the entire manufacturing process is handled by a computer-generated program. High price materials and the latest technology both do not come cheap. Therefore, the CNC shift knobs are a bit expensive.

But CNC shift knobs are highly precise and very much durable. So, though they are expensive, they will sustain a long time, making them cost-effective.

Common Materials Can Be Machined To Shift Knobs

Various materials can be machined to shift knobs. The weight of the shift knob will determine which materials you will use. Typically shift knobs can be built with aluminum alloy, stainless steel, wood, or carbon fiber.

Stainless steel is widely used in manufacturing shift knobs. You will see many wooden shift knobs too. They are lightweight and do not last long.

If you want a durable and heavy shift knob that lasts forever, aluminum alloy is the best choice. There could be various aluminum alloys, but the alloy that makes your shift knob durable and everlasting is Aluminium 6061 – T6.

You can build your shift knob from aluminum and then anodize them with your preferred color. CNC machining technology is used to manufacture shift knobs from an aluminum alloy.

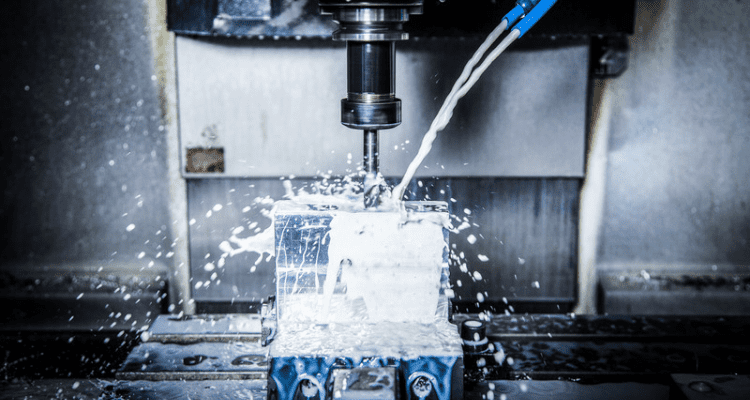

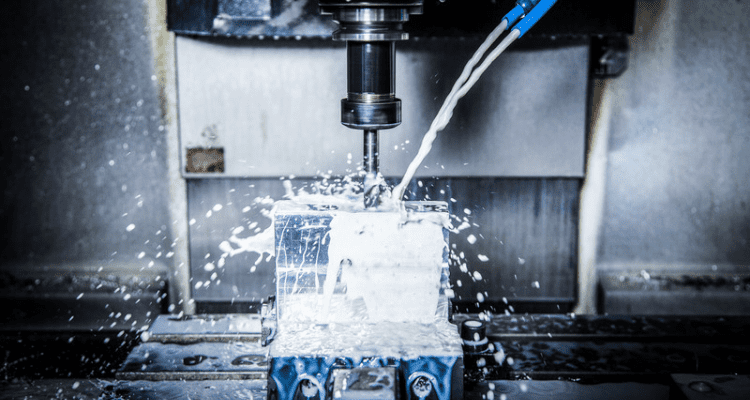

CNC Machining Technology for Producing Shift Knobs

- CNC Turning: CNC turning is one of the popular machining processes for some types of Shift Knobs, particularly cylindrical ones. It includes the rotation of workpiece and cutting tools to remove materials, forming external contours of Shift Knob.

- CNC Milling: In other more sophisticated Shift Knob designs, CNC milling is used to create a variety of shapes and curvatures. These include planar surfaces, grooves, patterns and special features.

- CNC Threading: Shift Knobs call for internal or external threads to attach the shifter. CNC threading guarantees the precision and quality of these threads.

- CNC Drilling: In order to mount the Shift Knob onto the shifter, holes may need to be drilled by CNC in case bolts or threads are incorporated.

- CNC Engraving: CNC engraving is a precise form that could be used to add logos, text or decorative patterns on the Shift Knob.

- Surface Finishing: CNC machining is followed by surface finishing which can either be polishing, anodizing or other coatings that improve the knobs look and strength.

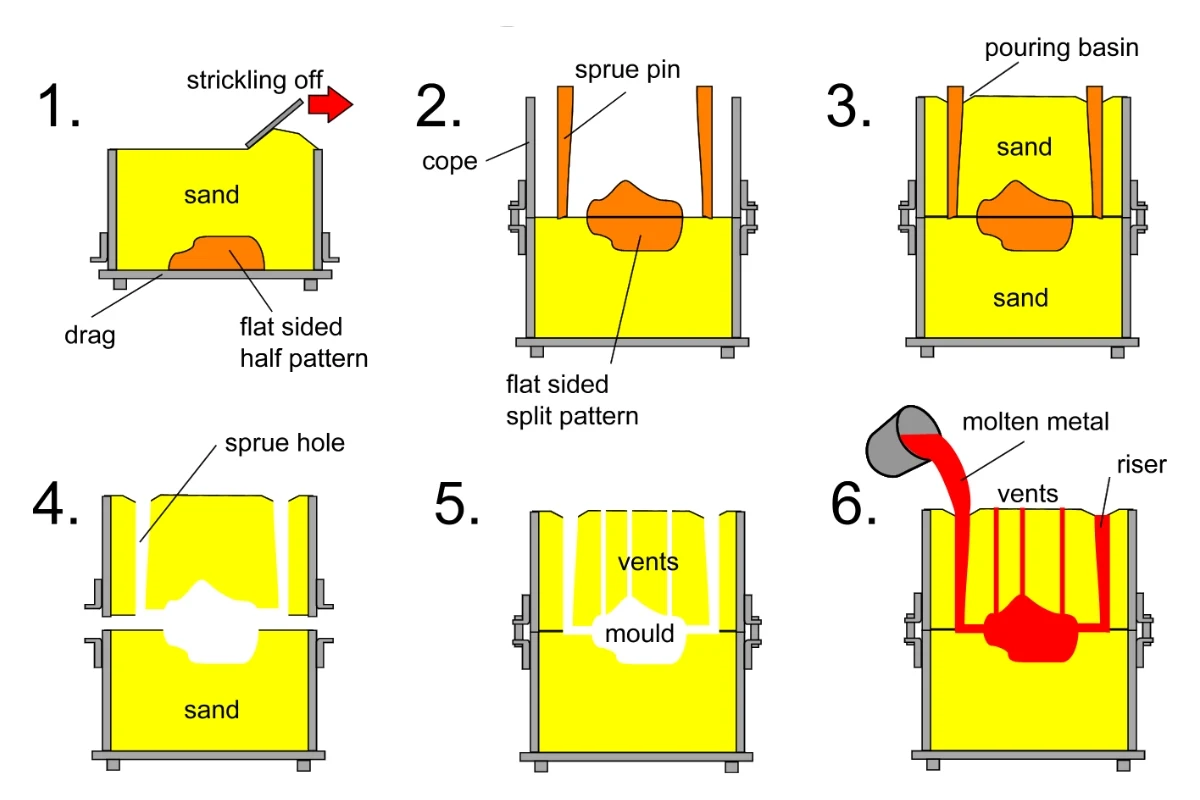

Make a CNC Shift Knob

CNC machines are entirely computer-controlled machines. So, the manufacturing of CNC shift knobs is altogether done by a computer program.

To prepare for the program, first, you have to create the design. To achieve that, you have to use software that is capable of designing CNC shift knobs. Typically CAD software is used to design CNC shift knobs.

When the design is done, you have to upload the design to a CNC machine to manufacture the CNC shift knob. You have to pick the material that is perfect for obtaining the intended result. Aluminum is the most widely used CNC material.

Then CNC milling and turning machines will complete the process, and you will get your CNC shift knob.

The universality of CNC Shift Knobs

When you are looking for a shift knob, you will come across two terms, “Universal shift knob” and “Vehicle Specific Shift knob.” CNC shift knobs can be of both types.

Most custom CNC shift knobs are universal shift knobs. Universal shift knobs are made in a way that you can use them on any model or any car.

You can screw universal shift knobs at the top of any stick shift rod. If the shift knob does not fit the shaft properly, you would need an adapter kit to fit the universal CNC shift knob atop the shifter.

Custom CNC Shift Knobs

CNC shift knobs are highly customizable, which is why they are so popular these days. You can get customized universal-fit knobs or vehicle-specific fit knobs.

Custom CNC shift knobs have custom designs and dimensions that you will not find in any standard vehicles. It can help you to put your favorite pets dummy or anything that adds some humor to the interior of your car. In short, a custom CNC is a more personalized CNC shift knob.

Measure a Shift Knob Thread

The process is pretty straightforward. Extract the threaded area and grab a ruler. Now put it along with the bolt or screw. Now count how many threads are there in 1 inch. Now measure the diameter and note the information.

You can also use a tread gauge to measure the shift knob thread. If you are not comfortable with that, bring your car to a repair shop and ask them to measure the shift knob for you.

Common Threads On The Shift Knob

The shift knob thread size may vary from vehicle to vehicle. The thread size depends on the model, package, and trim. The thread size is also very for performance and after-market shifter. Here are some of the most common threads on the shift knob:

Acura – Manual 10mm x 1.50

AMC AMX – Manual 1969 3/8-24

B&M 45044 Corvette C5, C6, Z06 (For 1997-2007)

B&M 45108 12mm x 1.50

B&M 81152 Wrangler JK 3/8-16 (For 2007-2018 Jeep)

Barton – Camaro Factory Adapter 3/4-16 (2013 and newer )

Barton – Challenger Shifter 12mm x 1.25

Barton – Mustang Shifter 12mm x 1.25 (2011BM-1)

Bowler Transmissions 3/8-16

Chevrolet Blazer 3/8-24 (Manual 1973)

Chevrolet Blazer – 7/16 – 14 (Transfer case 1989)

Chevrolet Camaro – 3/8-16 (Manual 1970 to 1981)

Chevrolet Chevelle 9/16-18 – 4 speed

Chevrolet Corvair 5/16-18 (Through 1963)

Dodge Challenger™ 8mm x 1.25 (Newer – manual)

Dodge Magnum™ 8mm x 1.25 (Manual)

Ford Fairlane™: 1/2 – 20

Ford GT™ – 12mm x 1.75 ( Manual 2005)

Ford Mustang™ 12mm x 1.75 (Manual 1979 to 2004)

We have listed some cars here. If you don’t find your car in the list just search the thread size with the model number of your car. There are lots of websites that provide this information.

Choose The Best CNC Shift Knob Manufacturer

We hope now you have a better idea than before about CNC shift knobs and are ready to manufacture for yourself. But how do you choose a CNC shift knob manufacturer? CNC machining is a delicate process, and you just can select anyone.

Allow us to help you with our expert suggestion so that you can pick the best CNC shift knob manufacturer.

Knows Everything About CNC Machining

The CNC shift knob manufacturer should understand the technology very well. From design to the engineering team, From machine operators to the post-production team, they should be well equipped with experienced workers.

Modern Equipment

The CNC shift knob manufacturer must have access to cutting-edge CNC machining equipment. Ask them whether they have all 3,4,5 – axis CNC machines. Also, ask them whether they have all the supporting instruments and tools to operate a high-tech CNC machining factory.

Experience

Experience is crucial in every industry, but it is more critical when it comes to CNC machining. CNC machines are wholly operated by computer programs and deliver nearly zero-tolerance products. Managing a sophisticated technology like this demands a year of experience.

Various Surface Treatments

An excellent CNC knob shift manufacturer should have various surface treatments ability. As a customer, you don’t want to decide from a few options when it comes to surface treatments. Users want a lot of options when they come to choosing CNC shift knobs and various surface treatments provide those options to them.

Packaging

CNC shift knobs, as well as any other CNC machining parts, are incredibly delicate parts. Therefore, the manufacturer must pack your CNC machined parts while maintaining proper precautions. Packaging saves your CNC shift knobs from scratching during shipping.

Guidance for Custom CNC Shift Knob

In order to customize CNC shift knobs, start by clearly defining your needs and find a reliable manufacturer. During the close collaboration with the manufacturer’s design team, request and compare price quotes to help finalize specific details of knob design and material selection. Talk about surface finishes and quality control procedures, sort out lead times and costs, and keep communication channels open during the customizing period. If it is viable, ask for a sample or prototype prior to finalizing the terms. Perform a full quality inspection as soon as the custom shift knob is delivered and provide comments to ensure further collaboration with the manufacturer.

Conclusion

Standard shift knobs are okay for your automobile, but if you want to add an aesthetic look, there is no other option other than a CNC shift knob. Moreover, they are easy to grip, durable, and sustain for long years. However, you have to choose the suitable material and, of course, the proper manufacturer before choosing your CNC shift knob.

Resources: