CNC Titanium Prosthetic Parts: Revolutionizing Prosthetics with Precision

Delve into the world of CNC titanium prosthetic parts, exploring their benefits like strength, biocompatibility, and versatility. This article explains how CNC machining contributes to modern prosthetics, offering customized and durable solutions for patients.

Understanding CNC Titanium Prosthetic Parts

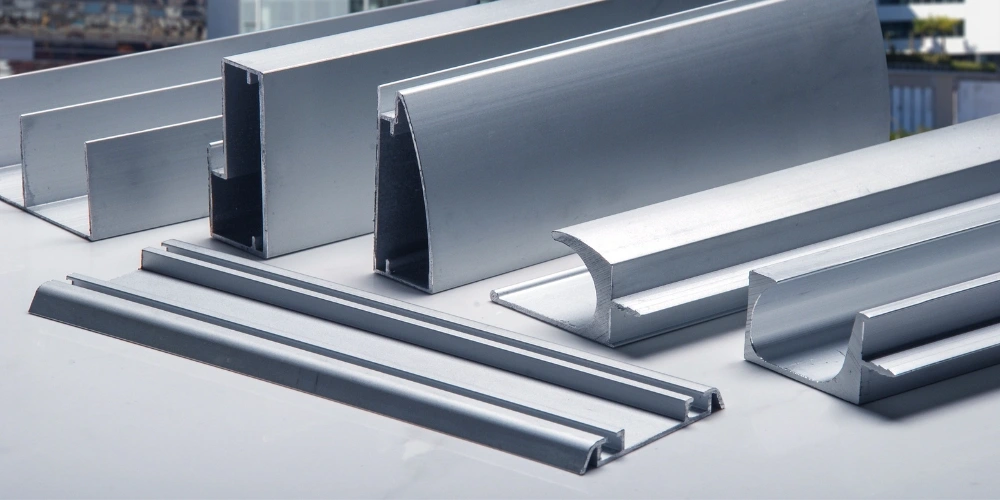

CNC-machined titanium prosthetic components are prosthetic parts manufactured using CNC machining processes. These components are crafted from titanium, a lightweight and high-strength metal renowned for its biocompatibility and durability.

Benefits of Using Titanium for Prosthetic Parts

Titanium was chosen for its outstanding properties as a prosthetic component:

Strength: Titanium’s high strength and light weight make it ideal for the manufacture of durable, functional prosthetic components.

Biocompatibility: Titanium is biocompatible, minimizing the risk of adverse reactions when in contact with the human body.

Corrosion Resistance: Titanium’s corrosion resistance ensures long-term use, especially in challenging environments.

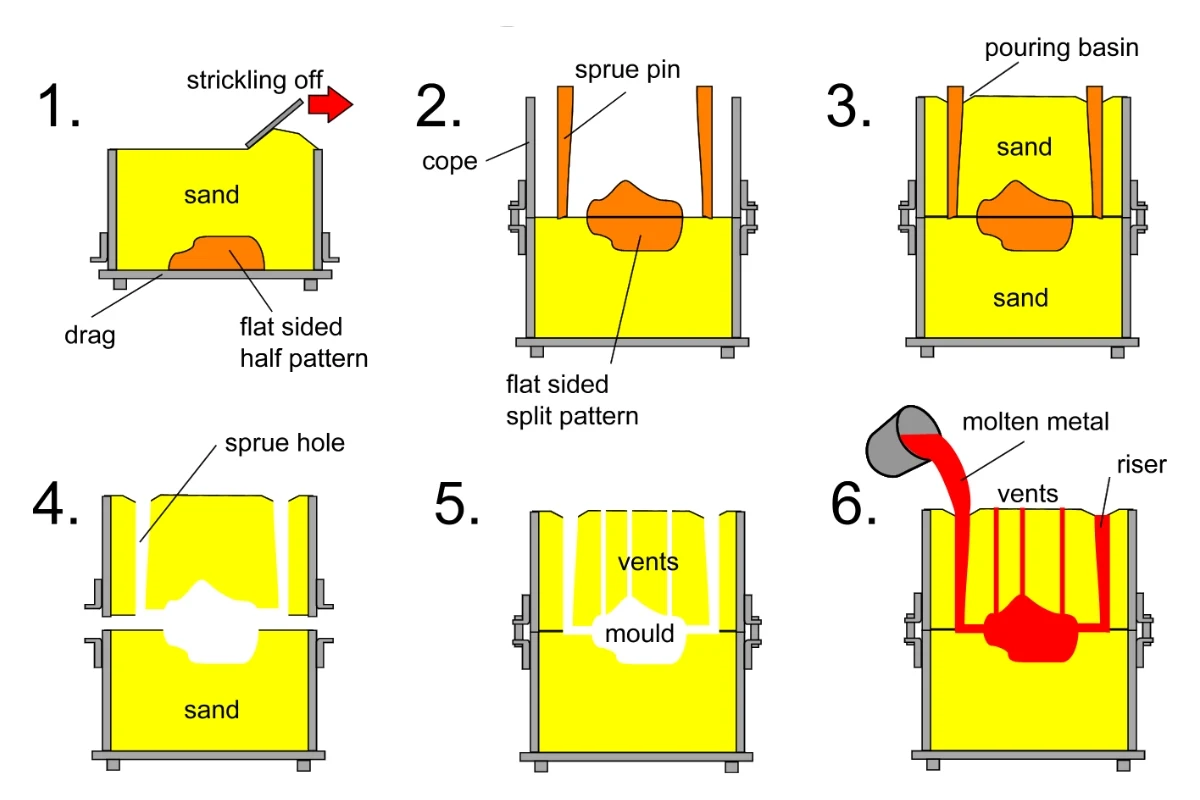

What is CNC machining for titanium prosthetic parts?

CNC machining is a precision manufacturing process that, with the aid of computer-controlled machines, accurately removes material from a whole block of titanium, which is then machined into a prosthetic component according to design specifications.

Benefits That CNC Titanium Prosthetic Parts Offer

CNC titanium prosthetic components offer several advantages, including:

Precision: CNC machining ensures dimensional accuracy and consistency, which is critical to creating a well-fitting prosthetic component.

Personalization: Each component can be customized to meet an individual’s unique needs and specific prosthetic design.

Durability: The strength and corrosion resistance of titanium extends the life of prosthetic components.

Complex Designs: CNC machining can create complex geometries and features that may not be possible with other manufacturing methods.

Are CNC Titanium Prosthetic Parts Suitable for All Types of Prosthetic Limbs?

Indeed, CNC titanium prosthetic components are suitable for different types of prostheses, including upper and lower limb prostheses. Their feasibility depends on the specific needs of the user and the type of prosthesis.

Can CNC Machining Create Prosthetic Parts With Precise Alignment Features?

Indeed, CNC machining enables the manufacture of prosthetic components with precise alignment features to ensure that prostheses are fitted and aligned correctly.

Can CNC Titanium Prosthetic Parts Be Customized for Cosmetic Purposes?

Yes, CNC machining allows for customization of prosthetic parts for cosmetic purposes, including adding textures, patterns, and other visual elements that match the user’s preferences.

Can CNC Titanium Prosthetic Parts Be Integrated With Other Prosthetic Technologies?

Of course, CNC titanium prosthetic components can be combined with a variety of technologies such as sensors, motors, and electronics to enhance the functionality and usability of the prosthesis.

How Long Does It Take to CNC Machine Titanium Prosthetic Parts?

The time required to manufacture CNC machined titanium prosthetic components can be affected by factors such as the complexity of the design, the size of the component, and the machining parameters. Machining a simple part may be quicker, while machining a complex part may take longer.

How Can I Get CNC Titanium Prosthetic Parts?

For CNC titanium prosthetic components, work with a manufacturer or machining service that specializes in medical device manufacturing. Work closely with your prosthetist to ensure that the part meets your specific needs and can be effectively incorporated into your prosthetic system.

Conclusion

The integration of CNC machining and titanium in the realm of prosthetic parts represents a remarkable leap forward in the quest for more functional and customized solutions for individuals in need. The precise nature of CNC machining allows for the creation of prosthetic components that align seamlessly with a patient’s anatomy, leading to improved comfort and mobility, the biocompatibility and durability of titanium contribute to the longevity and reliability of these prosthetic parts.

Resources: