Metals are solid parts used in various industries to build, shape, and support tools and machines. They are split into two main groups, which are ferrous and non-ferrous. This difference affects strength, rust resistance, cost, and recycling. Knowing which type to use helps avoid failure, saves time, and money.

What Is a Ferrous Metal?

Ferrous metal is a type of metal that basically contains a lot of iron, which gives it strength and makes it very hard. The name comes from the Latin word ferrum, which means iron. These metals are used in many industrial projects.

Core Properties

Magnetic

Their high iron levels make them attracted to magnets. This makes them very useful in motors and other kinds of devices.

High Tensile Strength & Durability

They are very strong, which means they do not bend or break easily under high pressure or heavy weight. Along with their strength, ferrous metals are also very durable, which means they can be used for years under stressful conditions.

Prone to Rust

It forms rust when it comes in contact with water and air. This makes the metal weak over time, and it’s one of the main problems with ferrous metals. However, they can be coated or alloyed to keep water and air out. A metal, like galvanized steel, is coated with zinc to keep water and air out.

Common Types of Ferrous Metals

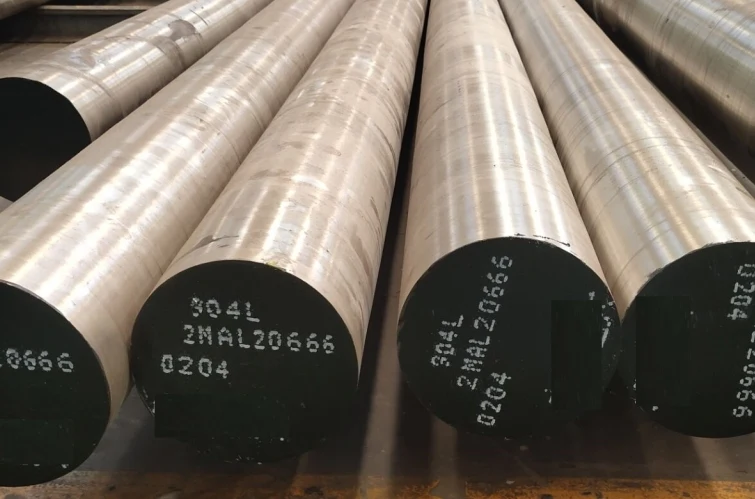

Steel

Steel is iron mixed with carbon, which makes it a lot harder and stronger. It is easy to cut, weld, and shape. It’s the most widely used metal today. Some subtypes of steel are:

Carbon Steel

This is a type of steel with carbon content usually up to about 2.1% by weight. The carbon content is usually what determines its strength and hardness. Low-carbon steel is soft and simple to form. High-carbon steel, however, is much harder and holds a sharp edge.

Alloy Steels

These are mixed with other elements such as Nickel, Chromium, and Molybdenum. These elements are used to enhance properties like rust-resistance, strength, and hardness. Some other alloys can be made to withstand heat or wear in different conditions. For example:

Stainless Steel

This is a type of alloy steel that contains Chromium. The Chromium forms a passive oxide layer that protects the material from rust.

Cast Iron

Cast iron has a very high carbon content, which makes it very strong under pressure. However, it can crack when something hard hits it. On the other hand, it resists wear very well, which makes it good for parts that face friction.

Wrought Iron

This type of metal has very little carbon in it. Due to this, it is very soft and easy to shape. It is used in industries because it resists rust better than many other ferrous metals.

What Is a Non‑Ferrous Metal?

These were the first metals used by humans for metallurgy. They have very little iron, and most of them contain less than 1% of iron.

Key Properties

Magnetism

Most non-ferrous metals are not affected by magnets, which makes them very useful in areas where magnetic fields can interrupt performance. However, some of them, such as nickel and cobalt, can be affected by magnets.

Density

Some non-ferrous metals like aluminium do not weigh as much as steel and iron. This makes it very easy for them to be handled, transported, and installed, especially when it comes to large-scale production lines. Some others, such as lead and nickel alloys, are considerably heavier.

Corrosion Resistance

Non-ferrous metals are naturally resistant to rust. This makes them ideal for outdoor use and other kinds of equipment. However, they can still corrode or oxidize in other ways, depending on the environment or chemicals they come in contact with.

Electrical/Thermal Conductivity

Some of these are also very good at conducting heat and electricity. They are essential in various industries, and their conductivity ensures that there is efficient energy transfer in appliances like electrical grids. Still, many non-ferrous metals are very poor conductors of electricity, such as Bismuth.

Common Types of Non‑Ferrous Metals

Aluminium

Aluminium is a lightweight non-ferrous metal. Thanks to its affinity for oxygen, it forms a hard oxide layer that protects the surface from rust.

Copper & Alloys

Copper is very soft and can bend without breaking. It is one of the best conductors out of all non-ferrous metals, which makes it a top choice for wiring. Copper also has alloys such as:

- Brass: This is an alloy made with copper and zinc. It is very easy to machine and also resists corrosion well. Thanks to its low friction, it’s usually used in mechanical systems.

- Bronze: This is a copper alloyed with mostly tin. However, other elements such as aluminium or phosphorus may also be included. It is tougher than pure copper and is also resistant to rust.

Lead

Lead is heavy and also soft. It melts at low temperatures, but it is heavily regulated because of how toxic it is.

Zinc

This is known for protecting steel through a process called galvanization. It also has a very low melting point. It is easy to shape, but heat may be required to prevent the structure from cracking.

Tin

This metal is soft, resistant to rust, and it bonds well to other metals. It is mostly used to coat steel and improve corrosion resistance in alloys.

Titanium

This is known for its exceptional corrosion resistance because of its stable, protective film. It also offers one of the best strength-to-weight ratios.

Precious & Specialty Metals

Metals like gold and silver are very good conductors, and they are resistant to corrosion as well. Platinum is another special metal that resists both chemicals and heat.

Side‑by‑Side Comparison Table

To understand these metals better, compare their traits side by side:

| Property | Ferrous Metals | Non-Ferrous Metals |

| Iron Content | They typically contain a large amount of iron. | Non-ferrous metals have very low to no iron content. |

| Magnetic | Most ferrous metals are magnetic. | Not all non-ferrous metals are non-magnetic. |

| Corrosion resistance | Without coatings, these metals rust quickly when exposed to air and moisture. | They naturally resist corrosion even in harsh conditions. |

| Density | Ferrous metals typically have high density. | Density varies extremely widely. |

| Conductivity | They have high electrical resistance and lower heat transfer. | Many non-ferrous metals are poor conductors. |

However, some metals break these general rules. For example:

- Stainless Steel: This is a ferrous metal, but it is resistant to rust, thanks to the chromium it contains.

- Titanium: This is non-ferrous, but still offers high tensile strength and relatively low density.

Applications & Use Cases

Ferrous Metals

Due to how strong and reliable they are, ferrous metals are used in areas that need strength and support:

Structural Engineering

Ferrous metals can be found in steel beams and columns, which are used to construct bridges, tunnels, and buildings. Railway tracks and train cars are also made from metals like steel and iron because of their long-term stability.

Heavy-duty Machinery & Automotive Components

Parts like press bodies, hydraulic parts, and gear housings are mostly made from steel or cast iron. Steel offers the impact resistance needed for forging, drilling, and mining, while cast iron is valued for its good wear resistance

In automotive and heavy transport, ferrous alloys are used to make crankshafts, axles, engine blocks, and transmission systems. In these areas, parts that can hold up well under stress for a long time are very important.

Non‑Ferrous Metals

These are mostly chosen in areas where precision matters more than brute strength, such as:

Aerospace and Transportation

Lightweight metals like aluminium and titanium are used as core components in aircraft frames and fasteners. Thanks to their lower density, it improves fuel efficiency and payload capacity.

Electrical Wiring, Gutters & Plumbing

Thanks to copper’s high conductivity, it is used as the industry standard for power lines, electric motor windings, and switchgear. It is also used in data centers and renewable energy systems where good energy transfer is important. Copper and Brass also resist corrosion, which makes them ideal for potable water systems used in plumbing.

In electronics, gold, silver, and copper are also used in circuit boards and connectors, where precise conductivity is vital. Zinc-coated components are also used a lot in roofing and gutter systems to manage exposure to weather conditions without constant maintenance.

Decorative & Precision Components

Gold, silver, and bronze are used to make rings, statues, and coins. Metals like brass, bronze, and aluminium are also preferred in architectural finishes, fixtures, and industrial design because of their appearance and corrosion resistance.

Recycling & Economic Factors

Metals are some of the most recycled materials in the world, but they are not all recycled the same way. Some also hold up better than others during the process.

Recycling Rates

Ferrous Scrap: Ferrous metals like steel and iron are widely recycled. Scraps can be gotten from old cars, buildings, and machines. However, they can lose quality each time they are melted to be reused. This can really affect the strength and durability of the metal.

Non-ferrous Scrap: The process for recycling non-ferrous metals is usually more careful and valuable. Metals like copper, aluminium, and brass can maintain their quality after many recycling processes. Because non-ferrous metals are worth more, they are usually sorted by hand or using machines.

Cost Differences

Iron is one of the most common elements that can be found. They are usually mined in huge amounts and refined into steel. This makes ferrous metals cheap to use in various applications. Even after being processed and shaped, they are still cost-effective.

On the other hand, non-ferrous metals are less common. Due to this, they cost more to extract and refine. Metals like gold, silver, titanium, and nickel are much rarer to get and process. This is why they are mostly called precious metals.

Choosing the Right Metal

When picking a metal, it’s important to know exactly what the job needs. Here’s a checklist to help you decide:

Check the Mechanical Strength Needed

If there are strong support beams needed, go with iron or steel. But for light and tough jobs, consider using titanium or aluminium.

Consider the Weight

If weight is an issue, like in planes or bikes, then it’s best to use aluminium or other light non-ferrous metals.

Factor the Corrosion Exposure

If the part is going to face the rain or salt, use metals like stainless steel, aluminium, or zinc. Plain steel or cast iron will need a coating.

Will It Need to Conduct Power or Heat?

Use metals like copper or silver for wiring or heating parts.

Check for Magnetism

If you need magnetic parts for components like motors, go for metals with high iron levels. But if there are sensitive components, then use non-magnetic metals like aluminium.

Formability

If you need parts that won’t crack, then it’s best to use metals like copper, low carbon steels, and wrought iron, which have high formability.

Review Your Budget

If the budget is tight, then use standard steel or iron, since they are much cheaper. However, if there is more need for performance in the projects, invest in non-ferrous metals.

Conclusion

The best material isn’t always the cheapest or strongest. It’s the one that matches the needs of the job. If the metal fails, then the system fails. If you’re unsure about what to select, HDC Manufacturing’s team can help you get it right with our expert support and high-quality supply.