Precision and Versatility in Plastic CNC Milling

Explore the transformative impact of Plastic CNC Milling in manufacturing, from the types of plastics used to the advantages and limitations of the process. Learn about suitable applications, the comparison with injection molding, and tips for finding a reliable CNC milling service. Understand why CNC milling is ideal for creating precise, complex plastic parts for various industries.

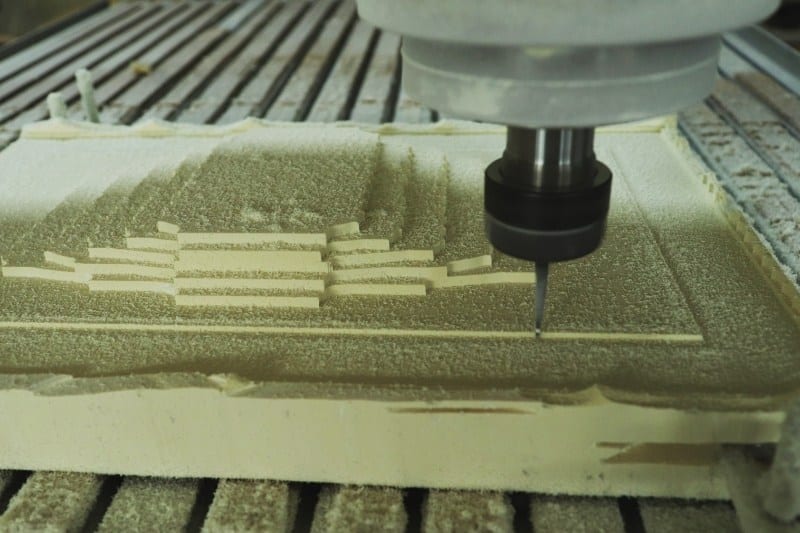

Understanding Plastic CNC Milling

Plastic CNC milling, referred to as computer numerical control machining of plastic materials is a process whereby machines controlled by computers shape and cut plastic workpieces into the desired shapes sizes ,and dimensions. In plastic CNC milling, a cutting tool (usually an end mill or router bit) is computer-controlled to cut and produce the specified product from a block of plastic. This process is generally used for prototyping, rapid manufacturing and production of plastic parts with high accuracy, precision and repeatability. It enables designing complicated geometries, finer details and customized plastic parts appropriate for numerous end-use industries like aerospace, automotive industry electronics medical devices etc.

Types of Plastic Parts Suitable for CNC Milling

CNC milling is a very adaptable manufacturing technique that can be used for different plastic parts such as prototypes, cases of enclosures and gears, specific components which have unique shapes or functionality; medical devices in addition to those from the automotive and areospace sectors; consumer goods along with display panels plus packaging units. It leads to accuracy and feasibility, which allows producing complex designs with precise tolerances for a range of sectors.

Applications of Plastic CNC Milling Parts

A variety of applications can be performed using plastic CNC milling parts, such as prototyping and electronic enclosures in addition to aerospace stuffs also medical devices. These plastic parts precision-machined find use in the areas of automotive, consumer products as well as packaging machinery industries thereby demonstrating their usefulness and accuracy. Given its ability to produce complex designs as well as custom components, plastic CNC milling is an important part of the process of making top-quality parts and products for different industrial application.

Pros of Plastic CNC Milling Compared to Other Plastic Processing Methods

Compared to other plastic processing methods, the precision of CNC milling machines wins hands down for versatility and applicability in a wider variety of intricate designs. It has a high level of accuracy, the ability to customize elements and compatibility with many types of plastic materials, minimizing any material waste required for adjustment while also allowing immediate changes in design. There is no need for expensive tooling, as opposed to other processes such as injection molding; it does not of costly required by small and medium productions. The reasons why plastic CNC milling enjoys widespread acceptance across industries and in specific prototyping both for complex as well as standard parts are due to its quick set up, reliability of quality standards with short lead times.

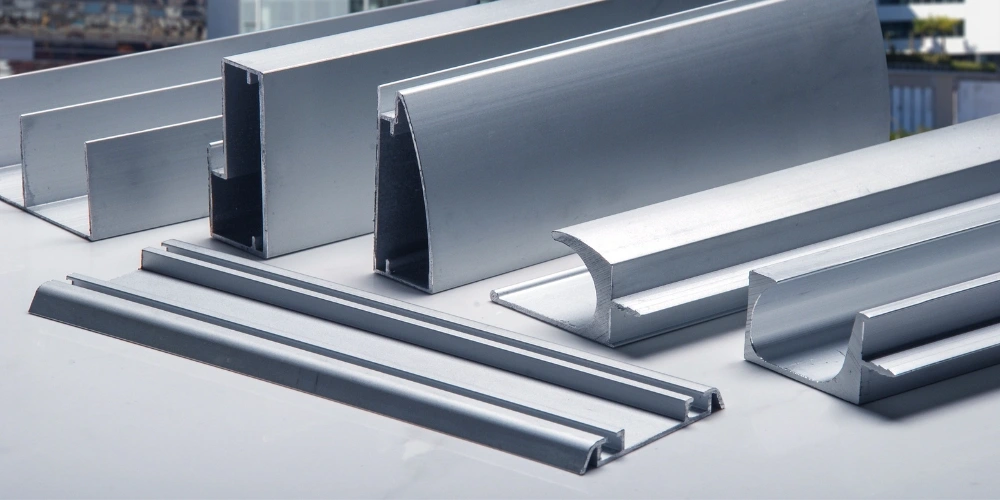

Types of Plastics Suitable for CNC Milling

Most thermoplastics and some thermosetting plastics can be CNC-milled. Common choices include ABS, acrylic, PVC, polyethylene, polycarbonate, and nylon. The choice of plastic depends on the specific requirements of the part.

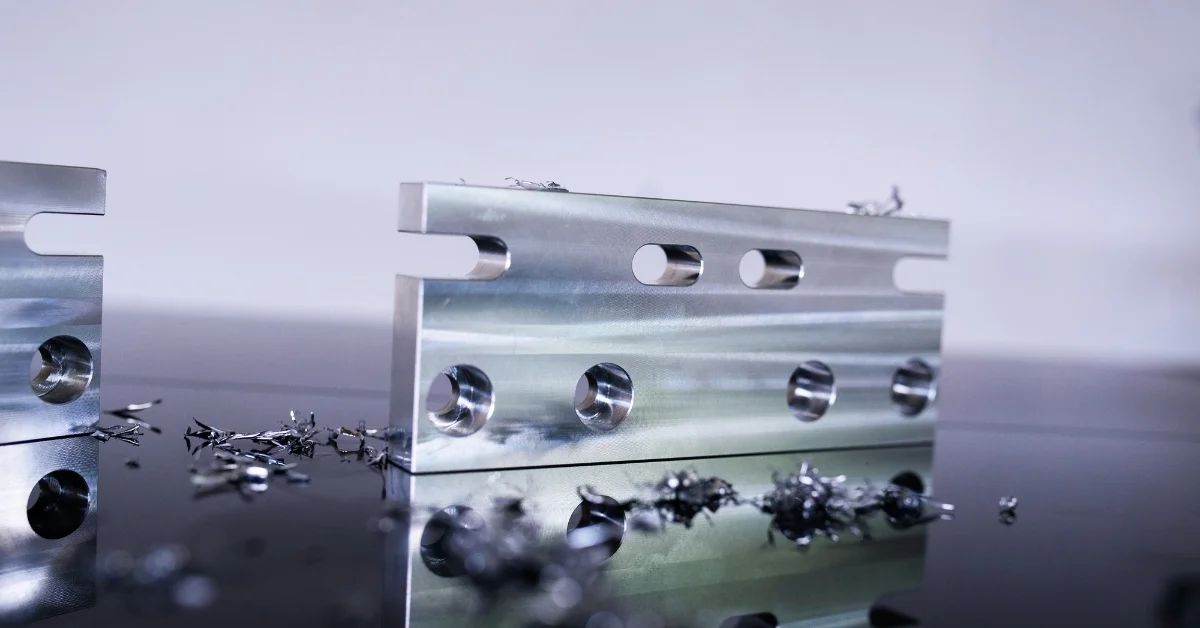

Limitations That CNC Milling Have on the Shapes of Plastic Products

- Undercuts: CNC Milling may have limitations in producing parts with complex undercuts, which require specialized tooling and can increase production costs.

- Intricate Internal Cavities: Extremely intricate internal cavities can be challenging to create with CNC Milling due to limited tool access.

- Sharp Internal Corners: CNC Milling may struggle with producing sharp internal corners, as the tool’s diameter affects the minimum corner radius.

- Thin Features: Very thin plastic features can be challenging to produce with CNC Milling, depending on material characteristics and tool capabilities.

- Limited Tool Access: The tool’s access to certain areas of a part is determined by the part’s geometry, and in some cases, reaching specific features for milling may be impossible.

Plastic Parts Produced by CNC Milling Require Secondary Processing

Plastic parts produced by CNC Milling may require secondary processing, depending on the specific requirements of the project. While CNC Milling produces highly precise parts, the surface finish may not always meet the desired aesthetics or functional needs. As a result, secondary processes such as polishing, painting, or assembly may be necessary to achieve the final product’s desired appearance and functionality. The need for secondary processing varies from project to project and is determined by the client’s specifications.

Plastic CNC Milling Suitable for Large-Scale Production

CNC milling is more cost-effective for low to medium-production volumes. For large-scale production, other methods like injection molding may be more efficient and economical due to shorter cycle times.

The Precision of Plastic CNC Milling Compare to Injection Molding

The precision of Plastic CNC Milling often surpasses that of injection molding. CNC Milling typically offers exceptional precision, often with tolerances in the range of 0.001 inches, making it suitable for producing highly accurate and intricate plastic parts. In contrast, while injection molding is efficient for high-volume production, its tolerances may be slightly lower due to factors such as tool wear. Therefore, if precision is a top priority for your plastic parts, CNC Milling is a preferred choice over injection molding.

Find a Reliable Plastic CNC Milling Service

If you’re searching for a dependable Plastic CNC Milling service, consider HDC CNC Machining. With a 13-year track record in OEM metal craftsmanship, we offer CNC milling for plastic materials. Our in-house facility, skilled team, and 4-axis/5-axis CNC capabilities ensure precision and innovation. We stand out for our commitment to quality, expedited delivery, and customized solutions for your project needs.

Conclusion

Plastic CNC Milling is a versatile and precise method for creating custom plastic parts. Understanding its capabilities, material suitability, and limitations is crucial when considering it for your project. Whether you need a prototype or a small production run, CNC Milling could be the answer to your plastic manufacturing needs.

Resources: