Mastering the Art of Metal Stamping: A Comprehensive Guide

Explore the intricate world of metal stamping in this comprehensive guide. Learn about the various techniques, applications, and the selection of materials that make metal stamping a pivotal manufacturing process in numerous industries.

Understanding Metal Stamping

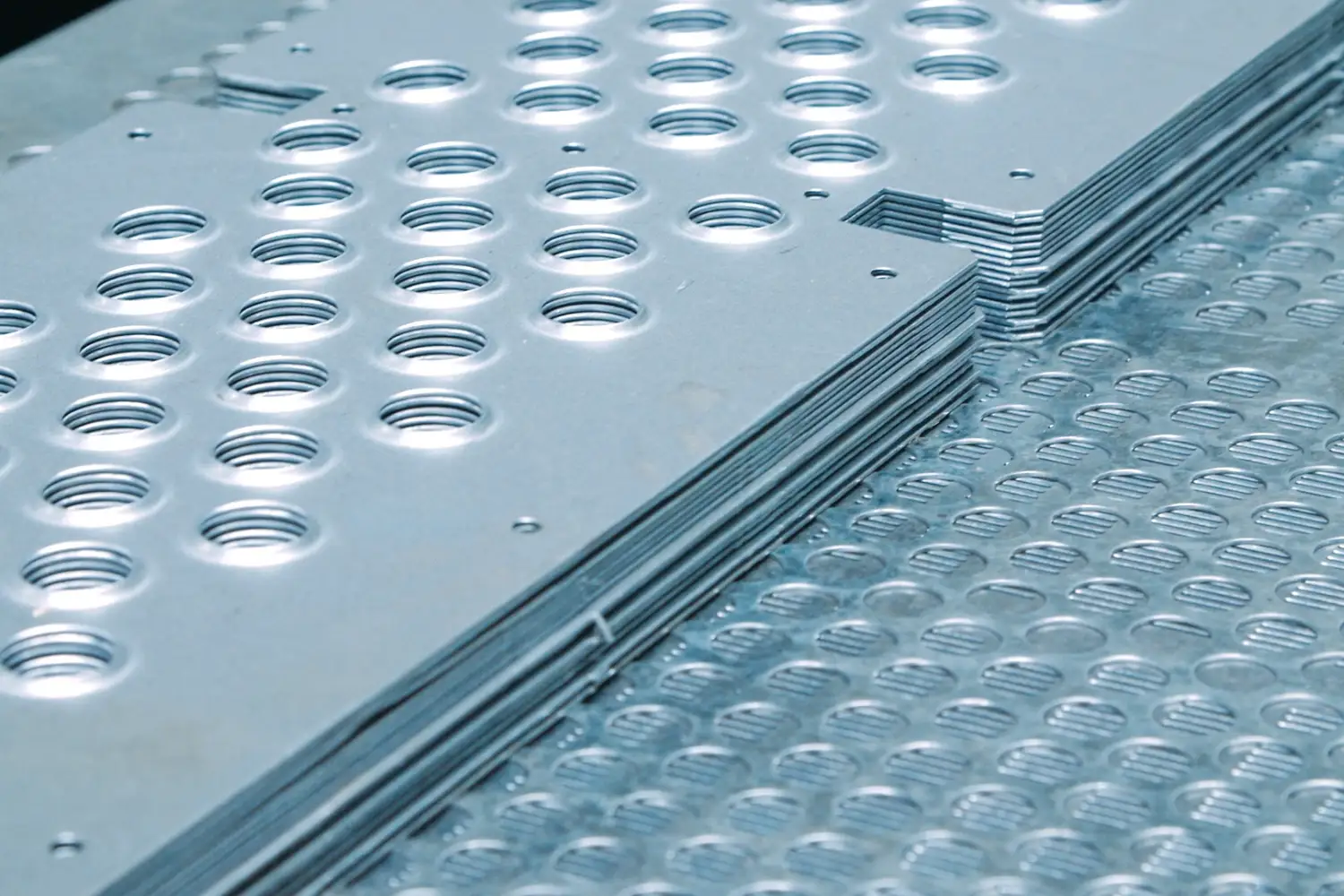

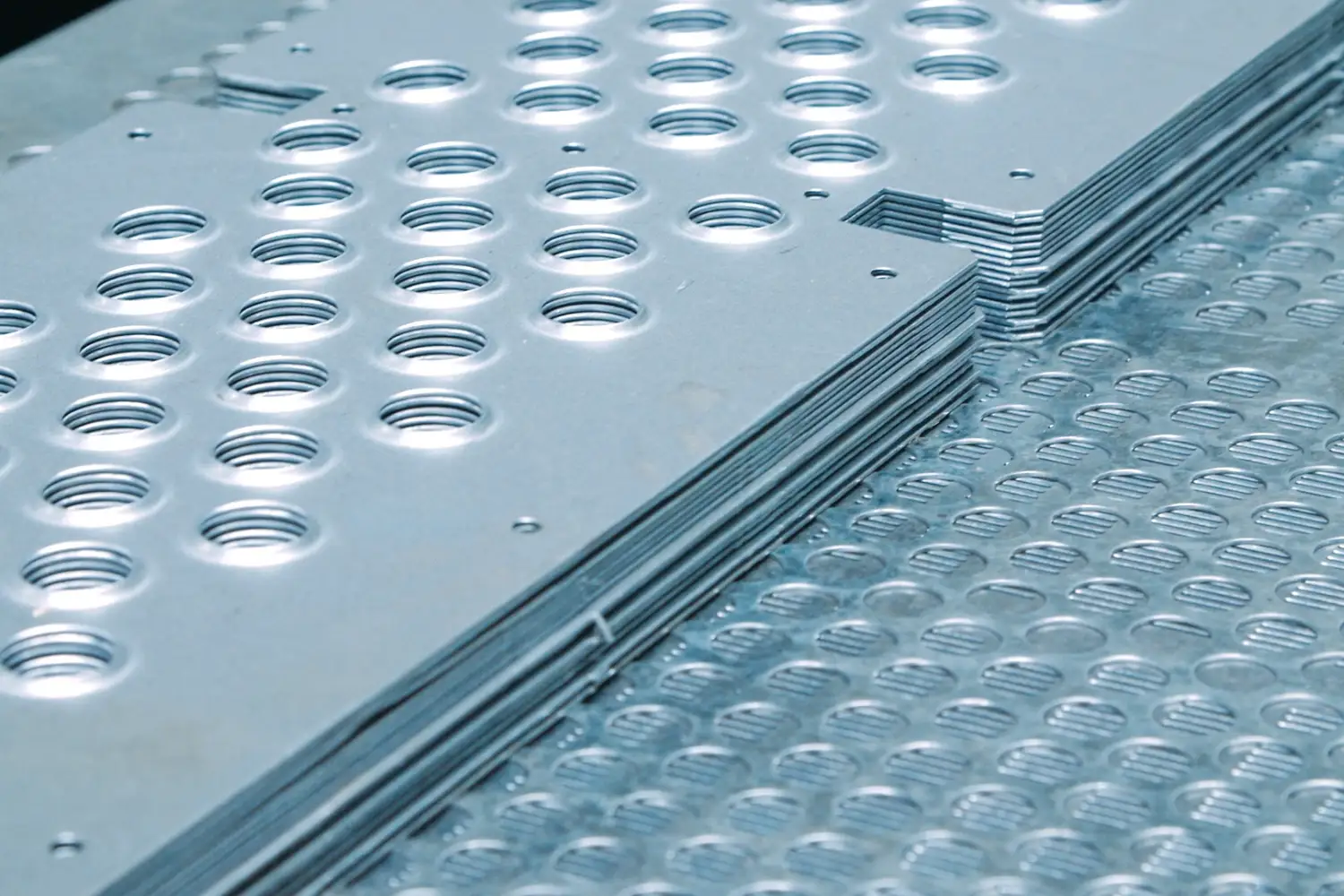

Metal stamping is a type of cold manufacturing procedure that’s purposely used to produce metal sheets into different forms, shapes, and styles of metal. The common misconception that people have with metal stamping is that it is the process of stamping any type of text or design into it.

In simpler terms, it is the transformation of fabricated metal sheets into different shapes. They are fed into a press, which utilizes a tool and die to form it into a new form and shape.

Common Products Made From Metal Stamping

Metal stamping has been regarded to as one of the best and most effective types of manufacturing processes there is. The most common products that are produced via metal stamping are automotive and aerospace parts, bicycle parts, motorcycle parts, industrial machinery components, medical and pharmaceutical instruments, oil and gas components, and many more!

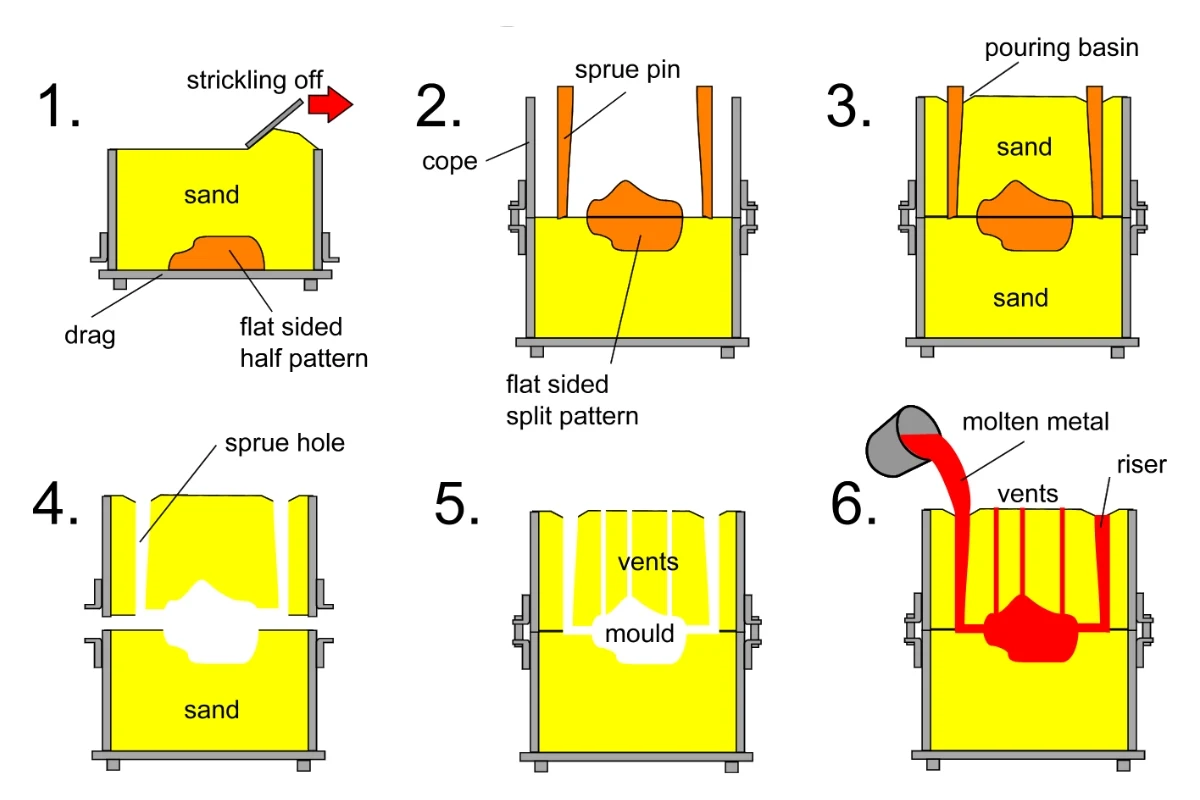

Basic Concepts of Metal Stamping

- Bending

- Blanking

- Coining

- Flanging

- Punching

- Embossing

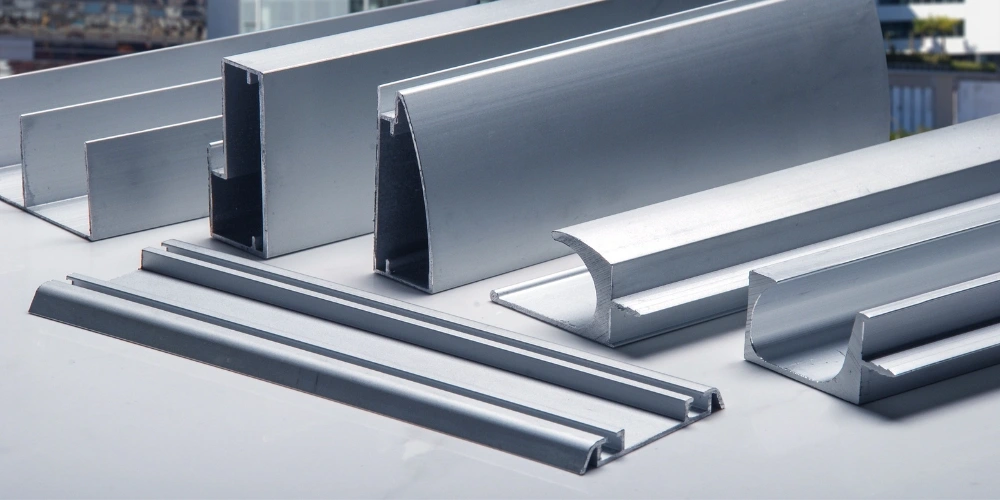

Types of Metal Stamping Parts

There are many different types and kinds of metal stamping parts you can purchase, but among the most common are medical, medicinal, and pharmaceutical components, furniture parts, appliance parts, automotive and motor vehicle components, and many more.

There are literally limitless applications of these metal stamping parts – whatever industry or equipment you can think of that utilizes customized sheet metal, you can consider them as metal stamping parts and/or components.

Applications of Metal Stamping Parts

Metal stamping components find extensive applications across a myriad of industries, spanning automotive, electronics, and construction. Revered for their exactitude and cost-efficiency, these integral elements play a pivotal role in the fabrication of body panels, connectors, and structural components, among others. The automotive domain relies on metal stamping to yield uniform, top-tier parts, while the aerospace sector capitalizes on its adeptness in crafting lithe yet enduring elements. Medical apparatus, consumer commodities, telecommunications, and the energy realm similarly exploit metal stamping for bespoke and standardized components. The adaptability and efficacy inherent in metal stamping position it as the method of choice for large-scale production of meticulous metal parts across a spectrum of applications.

Different Types of Stamping Dies

In metal stamping, there are quite a few types and categories of stamping dies. However, the most common are: progressive, line, and transfer.

Line production is the type of production ideal for extremely large parts and components and those that do not fit a single press. Transfer production, on the other hand, is slightly similar to line production but the dies are timed and used together.

Progressive production, lastly, considered the most used is the type of stamping where all dies are activated and tied together.

Metals Commonly Used in Metal Stamping

- Aluminum

- Stainless Steel

- Low Carbon Steel

- Copper

- Brass

- High-Speed Steel (HSS)

Pros of Metal Stamping

- Lower costs for dies

- Minimal and lower secondary costs

- Higher level of automation

- Less labor workforce

- Less expensive and cost-efficient

- Fast and easy to operate

Cons of Metal Stamping

- Separate acquisition of the dies is required

- Changing or modifying dies is difficult – the need to create a new one arises

- Higher upfront costs because of purchasing of presses and dies

Choose The Best Chinese Metal Stamping Parts Manufacturer

Chinese manufacturers of metal stamping parts are extremely trustworthy and reliable. In fact, a lot of businesses, companies, and organizations worldwide rely on Chinese metal stamping parts suppliers for the bulk or wholesale orders of their components!

Other than the fact that they can get it for extremely low costs, Chinese manufacturers of metal stamping parts also have proven track records of quality service, premium quality products, speed in delivery, and many more!

But which Chinese metal stamping parts manufacturer can you fully trust and bank on?

Get High-Quality Metal Stamping Parts

For all the metal stamping part needs you have, you can bank and count on us here at HDC Manufacturing. For 12+ years in service, we have produced and manufactured some a ton of different types and categories of metal stamping parts.

We’ve produced everything from metal stamped parts for construction, for appliances, for medical and medicinal equipment, for automotive and aerospace components, and many more!

Besides our expertise in the production of metal stamping parts, we’re also the best company when it comes to CNC rapid prototyping, laser cutting services, sheet metal fabrication services, and many others more!

Reach out to us if you ever find yourself in need of metal stamping parts whether in bulk or retail! Get a free estimate of the orders you need!

Custom Metal Stamping Parts From Manufacturers

In the quest for custom metal stamping components, embark on an exploration of esteemed fabricators renowned for their mastery and favorable commendations. Clearly delineate your requisites, encompassing materials, dimensions, and quantity. Dispatch a meticulous Request for Quote (RFQ) to the chosen manufacturers.

Assess quotations, contemplating not solely expenditure but also quality, manufacturing proficiencies, and delivery timelines. Assure that the designated fabricator aligns with stringent quality benchmarks and possesses pertinent certifications, ensuring alignment with your stipulated part specifications.

Foster transparent communication with fabricators, soliciting elucidation on uncertainties and engaging in discourse regarding potential alterations. Engage in negotiations covering terms and conditions, encompassing remuneration and delivery timetables. Document comprehensively within a formalized contractual agreement.

Conduct prototype examinations, when applicable, to ascertain the mettle of stamped components, particularly for extensive or pivotal orders. Conclude the accord with the chosen fabricator and uphold consistent communication during the production continuum to facilitate prompt issue resolution.

Conclusion

HDC, a trusted Chinese manufacturer of metal stamping parts for over 12 years, delves into the intricacies of metal stamping in industries like automotive, aerospace, and medical instruments. The blog focuses on the cost-efficiency and automation advantages while discussing the pros and cons of metal stamping. Globally, HDC and similar Chinese manufacturers play a vital role in fulfilling large orders due to their reliability and cost-effectiveness. With a proven track record, HDC excels not just in metal stamping but also provides a variety of high-quality metal components tailored to specific requirements.