Overview

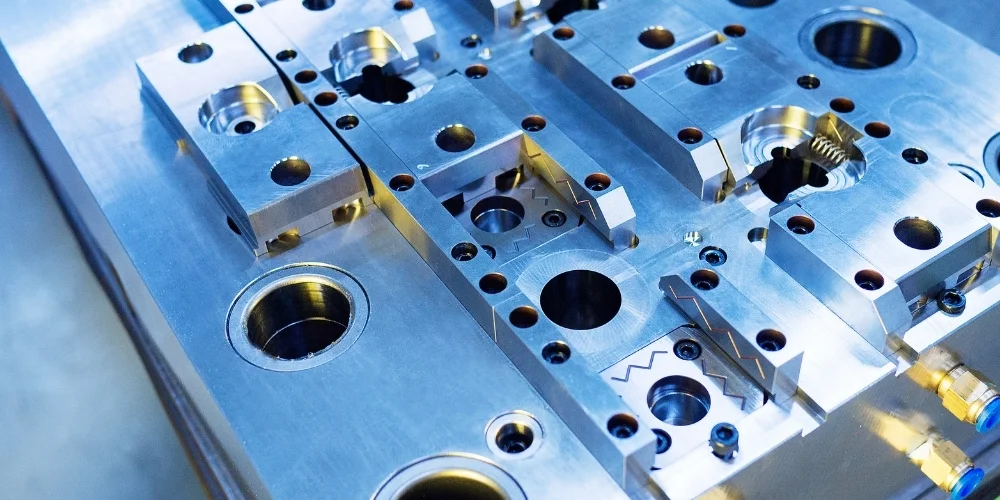

Nurturing a specialized adeptness in the meticulous casting of 303 stainless steel, we underscore our unwavering commitment to eminence within the realm of metal fabrication. Employing avant-garde technology and a proficient workforce, we distinguish ourselves in the convoluted procedures entailed in casting components of 303 stainless steel.

Our proficiencies in the casting of 303 stainless steel encompass a sweeping array of methodologies, embracing molding, pouring, and finalizing. This extensive acumen empowers us to navigate the distinctive tribulations presented by this grade of stainless steel, assuring superlative outcomes in both quality and efficiency.

Upholding an unswerving devotion to quality assurance, we steadfastly adhere to stringent benchmarks throughout the casting continuum. This pledge ensures the precision, uniformity, and dependability anticipated by our clientele. Opt for our services for your 303 stainless steel casting requisites, and witness the transformative impact that our proficiency and unwavering dedication to eminence can impart to your ventures.

[toc]

What is 303 Stainless Steel?

303 stainless steel is in fact, free-machine variant of the common austenitic 18/8 stainless steel (namely, 304 stainless steel). This form has added sulfur or selenium to increase its machinability characteristic, which makes it better to cut, drill, and do all machining operations compared to the standard 304 grade stainless steel. Sulfur or selenium modification causes the formation of chips as internal tearing points, thus, improving the chip formation process and reducing the tool life. Machinability of 303 stainless steel is good. Though 303 stainless steel has less corrosion resistance and weldability compared to 304 stainless steel. The material is often used in machining where there are many machining procedures, such as turning, tapping, and milling of parts.

What Are the Characteristics of the 300 Series Stainless Steel?

The 300 series stainless steels which include 304and 316 grades are characterized by good corrosion resistance, non-magnetic properties in the annealed state and high ductility, strength, and formability, making them suitable materials for different applications. This property is due to the presence of chromium, and as such they have resistance to chlorides in the sea or in brackish water. Because of their attractive formability and high-temperature resistance, they are perfect for manufacturing complex products and demanding applications where the parts are subjected to high temperatures, like heat exchangers and exhaust systems. These so-called stainless steels are widely used throughout the automotive, aerospace, food processing, chemical, architectural, and medical industries because of the combination of properties that they offer, enabling them to operate in situations requiring that combination.

What Are the Differences Between the 200, 300, and 400 Series Stainless Steel?

The 200,300, 400 series of stainless steel have compositional differences, corrosion resistance, magnetic properties and applications. The 200 series is made of chromium, nickel, and manganese which present some minor corrosion resistance, being at the same time non-magnetic. On the other hand, 300 series which is known due to its composition from chromium and nickel, stands out as a material with excellent corrosion resistance property, non-magnetic property, as well as versatility for various industries. In the 400 series, with chromium as the primary alloying metal, it shows a lesser degree of corrosion resistance and is magnetic, hence, commonly used in cutlery and decorative trims. In general, the 200 series is used for the cookware and the 300 series is highly applicable for the corrosion resistance and wide availability, therefore, the 400 series is intended for the magnetic applications that require a moderate corrosion resistance.

Chemical Composition of 303 Stainless Steel

| Component | Wt.% |

| Carbon (C) | 0.0 – 0.15 % |

| Chromium (Cr) | 18.0 % |

| Iron (Fe) | 69.0 % |

| Manganese (Mn) | 0.0 – 2.0 % |

| Molybdenum (Mo) | 0 – 0.6 % |

| Nickel (Ni) | 9.0 % |

| Phosphorus (P) | 0.0 – 0.2 % |

| Silicon (Si) | 0.0 – 1.0 % |

| Sulfur (S) | 0.15 % |

The Influence of Elemental Composition on the Properties of Stainless Steel 303

Elemental composition being a key factor, the properties of stainless steel 303 largely depend on the type of the material. Unlike the tool steel 18-8 (304) grade which is a free-machining version of the basic austenitic 18-8 stainless steel, this grade contains sulphur or selenium added to improve machinability. The sulfur and selenium inclusions are present, and such characteristics act as chip breakers that aid chip formation by diminishing tool wear. Even though this alloy is a bit less corrosion resistant and weldable than normal 304 stainless steel. Indeed it is, however, stainless steel 303 has excellent general corrosion resistance, mechanical properties, as well as formability, that make it suitable for numerous applications, including screw machining, fittings, shafts, valves, and fasteners which need extensive machining operations. Therefore, when the component has the right alloy composition and atomic distribution, machinability is optimized, but preservation of the other important properties, say, corrosion resistance, becomes a challenge.

Mechanical Properties of 303 Stainless Steel

| Mechanical Properties | Metric | English |

| Ultimate Tensile Strength | 690 MPa | 100000 psi |

| Tensile Yield Strength | 415 MPa | 60200 psi |

| Elongation at Break | 40 % | 40 % |

| Hardness, Rockwell B | 96 | 96 |

| Hardness, Brinell | 228 | 228 |

| Hardness, Knoop | 251 | 251 |

| Hardness, Vickers | 240 | 240 |

| Modulus of Elasticity | 193 GPa | 28000 ksi |

| Shear Modulus | 77.2 GPa | 11200 ksi |

Physical Properties of 303 Stainless Steel

| Physical Properties | Metric | English | Comments |

| Density | 8.0 g/cc | 0.289 lb/in² | |

Electrical Properties | |||

| Electrical Resistivity | 7.2e-005 ohm-cm | 7.2e-005 ohm-cm | |

| Magnetic Permeability | 1.008 | 1.008 | at RT |

Thermal Properties | |||

| CTE, linear 20°C | 17.2 µm/m-°C | 9.56 µin/in-°F | from from 0-100°C |

| CTE, linear 250°C | 17.8 µm/m-°C | 9.89 µin/in-°F | at 0-315°C (32-600°F) |

| CTE, linear 500°C | 18.4 µm/m-°C | 10.2 µin/in-°F | at 0-540°C, 18.7 µm/m-C at 0-650°C |

| Heat Capacity | 0.5 J/g-°C | 0.12 BTU/lb-°F | from 0-100°C (32-212°F) |

| Thermal Conductivity | 16.2 W/m-K | 112 BTU-in/hr-ft²-°F | at 100°C (212°F), 21.5 W/m-K at 500°C (930°F) |

| Melting Point | 1400 – 1420 °C | 2550 – 2590 °F | |

| Solidus | 1400 °C | 2550 °F | |

| Liquidus | 1420 °C | 2590 °F | |

Equivalent Materials of 303 Stainless Steel

| EU | USA | Japan | France | England | Sweden |

| EN | – | JIS | AFNOR | BS | SS |

| X8CrNiS18-9 (1.4305) | 303 | SUS303 | Z8CNF18-09 | 303S31 | 2346 |

The Price of 303 Stainless Steel

The price of 303 stainless steel is determined by other things like market demand, availability of raw materials, manufacturing costs, and existing economic conditions. Normally, 303 stainless steel is cheaper relative to other high-grade stainless steels such as 304 or 316, because it is simpler in composition and its nickel content is lesser. Nevertheless, there is an on-going trend for prices to change in reaction to the fluctuations of the market. To get the most recent and accurate pricing information, stainless steel suppliers can be consulted or industry publications, which keep track of metal prices on a regular basis, can be referred to.

What Challenges Are Encountered in Processing Stainless Steel 303?

Stainless steel 303 though being machined is far better than austenitic standard stainless steels but still needs special attention. Contemporary problems may comprise the adverse effects of hardening induced by the machining process, scuffing in high loads, and the presence of sulfur inclusions that negatively affect surface finish and mechanical properties. However, weldability difficulties arise after sensitization of welded joints and need for post-weld heat treatments or low-carbon filler metal. The attainment of a smooth surface finish, is sometimes challenging due to hardening and sulfur inclusions which requires proper tooling and processing. The right chip management is a vital requirement to prevent chip agglomeration and tool jamming during the machining process. As a whole, these problems require good control of machining parameters, preferable selection of tools and efficient process optimization to gain the wished part quality and productivity levels.

Applications of 303 Stainless Steel

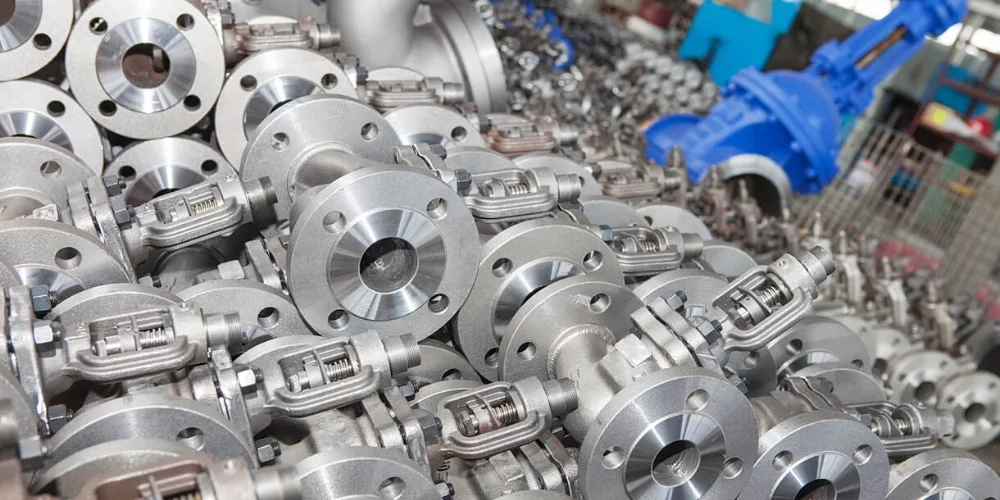

303 stainless steel, renowned for its corrosion resistance and machinability, plays a vital role in diverse industries:

- Automotive: Precision-crafted components like wheel spacers, block guards, valve covers, and intake flanges find frequent use in the automotive sector through the versatility of 303 stainless steel machining.

- Aerospace: Elevating aerospace applications, exhaust manifolds, impellers, pipe fittings, and valve bodies benefit from the excellence of 303 stainless steel machining, ensuring both durability and precision.

- Medical: In the medical field, 303 stainless steel lends its properties to create crucial components, including medical sensor power supply housings, precision elements, and prosthetic components, ensuring reliability and biocompatibility.

- Motorcycle: Revving up the motorcycle industry, 303 stainless steel is chosen for crafting radiator guards, exhaust end caps, clutch covers, and footpegs, delivering durability with a sleek finish.

- Trailer: Within the trailer manufacturing sector, the robust nature of 303 stainless steel is harnessed to create trailer hitch ball mounts, channel brackets, couplers, and pintle hooks, ensuring longevity and strength.

- Bicycle: Pedaling into the bicycle industry, 303 stainless steel components such as bike stems, chainrings, bicycle hubs, and cranksets contribute to lightweight and durable cycling solutions.

- Kart: Racing ahead in the kart industry, 303 stainless steel components like sprockets, wheel rims, wheel spacers, and wheel hubs enhance performance with their corrosion-resistant and machinable properties.

In each application, 303 stainless steel machining proves advantageous, offering a harmonious blend of corrosion resistance and ease of machining, making it the material of choice for intricate and complex parts.