Black oxide is a time-honored and widely used metal surface treatment. This blog outlines the process, benefits, and other aspects of black oxide. It serves as a reliable reference to help you choose the best surface finish, which can maximize the functionality of your custom metal products.

What is black oxide?

Black oxide, which is also called blackening, is a type of chemical conversion coating process mainly applied to ferrous materials like steel or iron. The metal reacts chemically with a specific alkaline oxidising solution to produce an extremely thin layer of iron oxide(Fe₃O₄) film. This film(about 0.5-1.5μm)is uniformly black and tightly bonded to the metal substrate.

Unlike iron-based materials that naturally oxidize and rust in air, black oxidation can serve as a surface treatment method. The core reason lies in the fact that in an alkaline environment, a dense black oxide film is formed through the combined effects of high temperature and oxidants, tightly bonded to the iron substrate.

Types of black oxide

Based on the operating temperature and the chemical solvent used, black oxide is generally divided into the following types:

Hot black oxide

The hot black oxide process operates at 140℃- 155℃. Immerse the metal workpiece in strong alkaline solutions such as NaOH and NaNO₂ to form a deep black and wear-resistant film on its surface.

This type is more suitable for high-performance tools and key precision parts.

Mid-temperature black oxide

The mid-temperature black oxide needs 90℃-120℃. Use modified alkaline solutions, which can react effectively at a lower temperature, to transform the workpiece surface into a black oxide film.

This type is safer and energy-efficient, while the coating performance is close to that of hot black oxide.

Cold black oxide

Unlike the above methods, cold black oxide utilizes acidic or neutral solutions (such as selenate and copper salts) to deposit black Cu2Se compounds.

This type may not be as perfect in performance, but it is fast and cost-effective, making it ideal for decorative pieces or indoor hardware.

The process of black oxide

Cleaning

Before black oxide, remove the grease and dust on the metal surface by using a hot alkaline cleaner. And then, rinse the workpieces with clean water to eliminate any residue of these solutions.

Pickling

Use an acidic solution, usually a diluted solution of hydrochloric acid or sulfuric acid, to dissolve the rust and oxide film on the workpiece. Afterwards, rinse with clean water to remove any residue to prevent it from contaminating the alkaline oxidation solution.

Black oxide reaction

This is the core step in the black oxide process. Metal parts are immersed in a specific black chemical oxidation solution to form a dense, black oxide film. This reaction typically takes 5-40 minutes, depending on the metal type and operating temperature.

Rinsing

After the black oxidation achieves the desired effect, take out the workpiece and clean it thoroughly with clean water and saponification solution to prevent the residual chemical solution from continuing to react chemically and causing corrosion.

Sealing/Oiling

Dip the parts that have been oxidized to black in oil, wax, or other sealants. When the sealant penetrates and fills the dense micropores on the surface of the parts, it enhances the rust resistance of the parts and provides a better visual appearance.

Pros and cons

Advantages

Dimensional stability

Because the black oxide film is very thin, about 0.5-1.5μm, it does not affect the size of metal parts at all, ensuring that high-precision parts meet tolerance requirements.

Corrosion resistance

The black oxide film after post-processing has an oil film or wax film that makes it waterproof, thus enhancing the corrosion resistance of carbon steel and other alloy steels, especially in humid and salt spray environments.

Durability

The black oxide film is tightly bonded to the metal substrate, it will not peel off by itself, nor will it come off due to changes in temperature, and it cannot be washed away with water or cleaners, so it can be used for a long time.

Reduce glare

The black matte finish can limit glare and light reflection, especially in bright environments, thus effectively meeting the lighting requirements of optical instruments and medical devices.

Lubricity

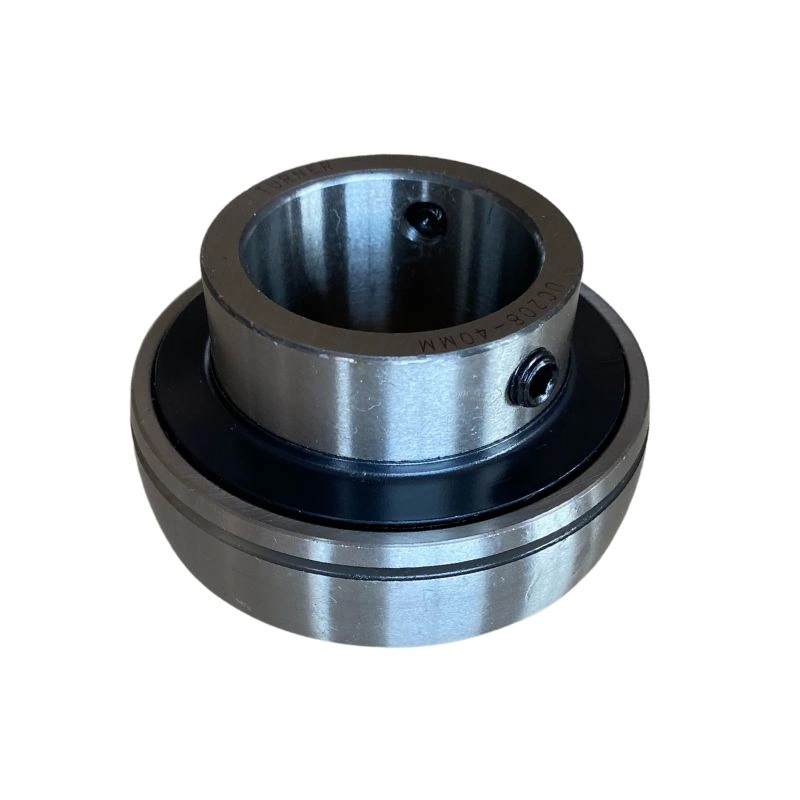

The oil film from post-processing provides lubrication to the black oxidized parts, which helps reduce the risk of friction, wear, and jamming in moving components such as gears and bearings during use.

Cost-friendly

Compared with other surface treatments, such as electroplating and powder coating, black oxidation has a low initial investment cost and mass production cost for your products.

Aesthetics

Black oxidation provides a uniform black appearance to your workpiece, offering decorative options for custom product surface design.

Disadvantages

- During the black oxidation reaction, wastewater containing acids, alkalis, and heavy metal ions is produced, which can pollute the environment if not properly treated.

- The surface pretreatment requirements are very high, and any residues on the surface will affect the final quality of metal products.

- The range of applicable materials is relatively narrow. It can only process materials such as carbon steel, stainless steel, and other alloy steels, but cannot process materials like aluminum and magnesium.

Application

Medical devices

Black oxidized parts are often used in medical devices, such as surgical knives and hemostatic forceps, to reduce the impact of light reflection on the doctor’s vision.

Hardware and tools

If you have mass-produced hardware parts waiting for surface treatment, such as hinges, nuts, bolts, and fasteners, black oxidation is a cost-effective method.

Automotive and aerospace parts

Black oxidation is a commonly used surface treatment process for critical components in automotive and aerospace applications, like suspension springs, shift forks, and landing gear components.

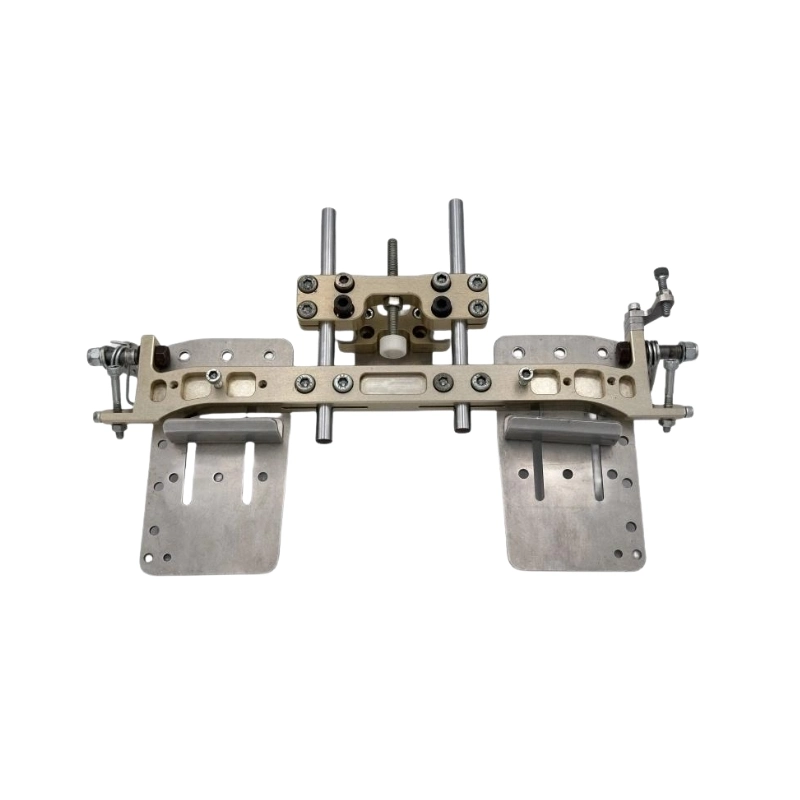

Mechanical components

Black oxidation ensures high-precision components such as gears, bushings, and drive shafts fit better during operation, which can enhance the performance and lifespan of your products.

Compared with other surface treatments

Black oxide vs black anodizing

Black oxide is suitable for carbon steel, stainless steel, and other alloy steel. While black anodizing is mainly applied to aluminum and aluminum alloys.

Black oxide vs zinc plating

Zinc-plated products allow for more color options, but the dimensions of parts will be affected by the thickness of the zinc coating. Generally, the thickness of the zinc coating is about 10 times that of the black oxide film.

Black oxide vs black phosphate

Black phosphate uses a completely different chemical solution with black oxide: acid phosphate, resulting in a grayish-black, thicker, better corrosion resistance film, whose main component is phosphate crystals, making it more suitable for an anti-rust bottom layer or pre-coating treatment.

Black oxide vs powder coating

Compared to black oxidation, powder coating offers a wider range of color options and is more corrosion-resistant; however, the thickness of the coating is about 100 times that of black oxidation, and the processing costs are also higher.

Conclusion

Black oxide is a cost-effective and reliable surface treatment for carbon steel, stainless steel and other alloy steel parts. If you have customized products that need black oxidation, whether they are forged, cast, CNC machined, or sheet metal processed, HDC can provide you with one-stop customized processing services. If you are interested, feel free to inquire about pricing, and we will promptly provide a quote based on your drawings or samples and offer high-quality product processing services.

Discover more with our blog posts.

Recent Posts

Discover more about our products

HDC Products

Instant Quote!