Table of Contents

Overview

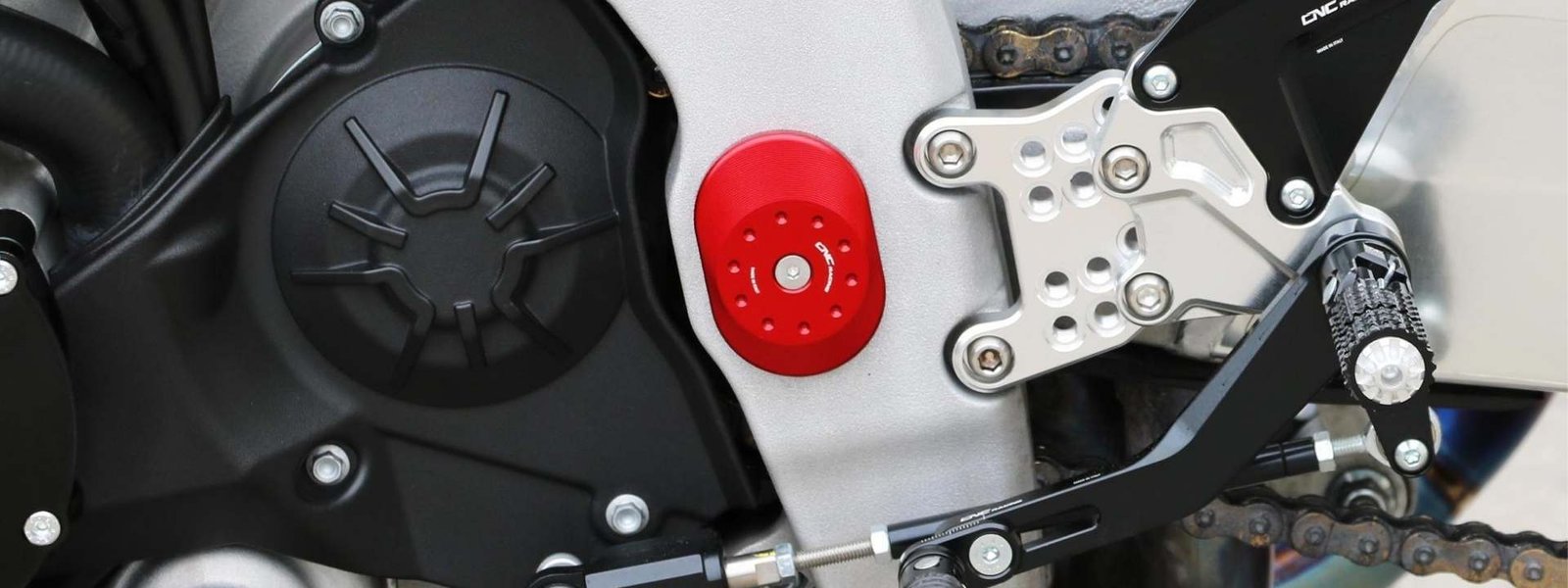

If you’re a car enthusiast or a racer, you’ve likely heard of CNC racing fuel caps. These small but vital components play a significant role in optimizing your vehicle’s performance. In this comprehensive guide, we will explore the world of CNC racing fuel caps, answering all your burning questions and shedding light on their purpose, materials, manufacturing processes, benefits, and more.

Understanding CNC Racing Fuel Cap

CNC racing fuel caps are specialized fuel caps designed to enhance the performance of racing vehicles. These caps are precision-engineered using Computer Numerical Control (CNC) machining, a process known for its accuracy and consistency.

The Purpose of a Racing Fuel Cap

Racing fuel caps serve a crucial purpose in optimizing a vehicle’s performance. They ensure a secure and airtight seal, preventing fuel from leaking or evaporating during high-speed races. Additionally, they allow for efficient refueling, saving valuable seconds on pit stops.

Materials Typically Used for Racing Fuel Caps

Racing fuel caps are typically crafted from lightweight yet durable materials. Common choices include aluminum, carbon fiber, and high-grade plastics. These materials offer a perfect balance between strength and weight, crucial for racing.

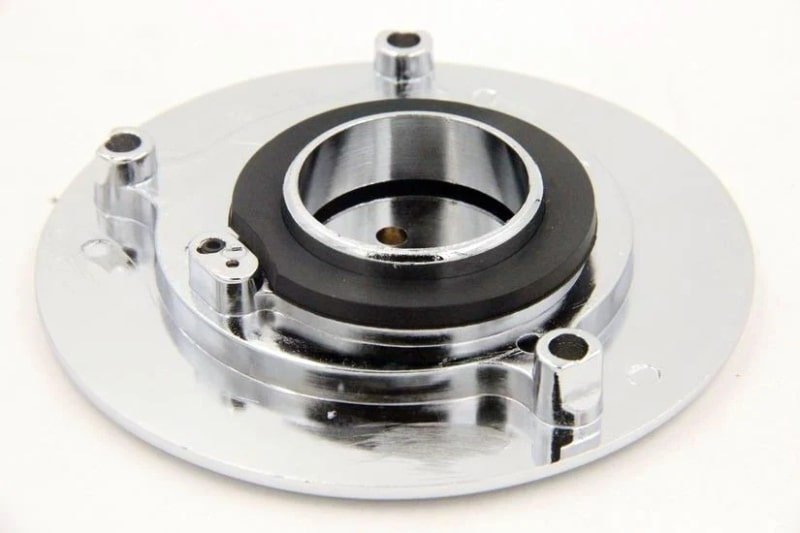

Processes Typically Used for Manufacturing Racing Fuel Caps

The manufacturing of racing fuel caps is a highly specialized process. CNC machining is the preferred method due to its precision. This process involves computer-guided machines that carve out intricate designs from raw materials with incredible accuracy. It ensures a tight seal and longevity.

Benefits of Using CNC Machining for Racing Fuel Caps

Using CNC machining for racing fuel caps offers several advantages. First and foremost, it ensures the highest level of precision and consistency. This leads to a secure seal, preventing any fuel leakage during races. Additionally, CNC machining allows for intricate designs and lightweight construction, contributing to overall vehicle performance.

Finishes Available for CNC Racing Fuel Caps

CNC racing fuel caps come in a variety of finishes to suit different preferences. Some popular options include polished aluminum, matte black, and carbon fiber patterns. The choice of finish not only affects aesthetics but can also impact durability.

Choose the Right Racing Fuel Cap

Selecting the right racing fuel cap is crucial for optimal performance. Consider factors like compatibility with your vehicle, the material used, the type of racing you’re involved in, and personal preferences. Consult with experts or refer to your vehicle’s manual for guidance.

The Universality of CNC Racing Fuel Caps

While many CNC racing fuel caps are designed to fit a wide range of vehicles, they may not be entirely universal. It’s essential to check compatibility with your specific make and model. Custom options are available for those with unique needs.

Impact of Racing Fuel Cap Types on Fuel Efficiency

The type of fuel you use can impact the choice of your racing fuel cap. Different fuels have varying characteristics, and some caps may be better suited for specific types. Ensure compatibility with your chosen fuel to prevent any issues.

Performance Enhancement of CNC Racing Fuel Caps

CNC racing fuel caps enhance performance by maintaining a secure seal, preventing fuel wastage, and enabling quick refueling. Their lightweight construction also reduces the vehicle’s overall weight, improving speed and handling.

Maintaining CNC Racing Fuel Caps

While CNC racing fuel caps are durable, they do require periodic maintenance. Regular cleaning and lubrication ensure their continued performance and longevity. Refer to the manufacturer’s guidelines for proper maintenance.

Cost Consideration When Custom CNC Racing Fuel Caps

While determining custom CNC racing fuel caps cost, a number of important factors must be taken into consideration. However, the selection of materials determines to a large extent equipment prices with high-end ones such as aluminum or titanium being costlier. Furthermore, the design’s intricacy and customization level could have a major influence on such cost increases since more complicated or peculiar designs may need greater inputs.

The quantity of fuel caps ordered is also essential; ordering larger quantities usually reduces the unit cost per cap because economies of scale are achieved. Other additions to the final cost can be custom finishes or coatings like anodizing, powder coating. Keeping in consideration the expertise of manufacturer and his reputation, as manufacturers may charge premium but their assurance can justify investment. Lastly, shipping and logistics expenses should be included as well because it is a vital factor for the international orders. A detailed cost estimate inclusive of all these parameters should be done in conjunction with the manufacturer to facilitate a decision based on an informed opinion.

Guidance for Custom CNC Racing Fuel Caps From Manufacturers

A systematic approach is necessary when looking for custom CNC racing fuel caps from the manufacturers. Carefully specify your needs, choose reliable manufacturers with appropriate certifications and ask for detailed estimates. Evaluate proposals by cost, lead time and modifications. Work together on the choice of materials, finalize designs that will make prototypes and develop an all-encompassing contract. Keeping the lines of communication open and conducting detailed inspections when you get your custom fuel caps ensures that they live up to specifications and performance standards. This systematic approach ensures a win-win partnership and quality manufactured custom fuel caps.

Conclusion

CNC racing fuel caps are more than just simple components; they are integral to enhancing your vehicle’s performance on the racetrack. By understanding their purpose, materials, manufacturing processes, and benefits, you can make an informed choice when selecting the right cap for your racing needs. Don’t forget to ensure compatibility, and remember that proper maintenance is key to their long-lasting performance.

Resources: