Precision Engineering Investment Casting Service One-stop investment casting service from...

Expert Superalloy Casting Service

Leading superalloy foundry providing precision superalloy casting parts to the global markets, for aerospace, energy, and industrial applications.

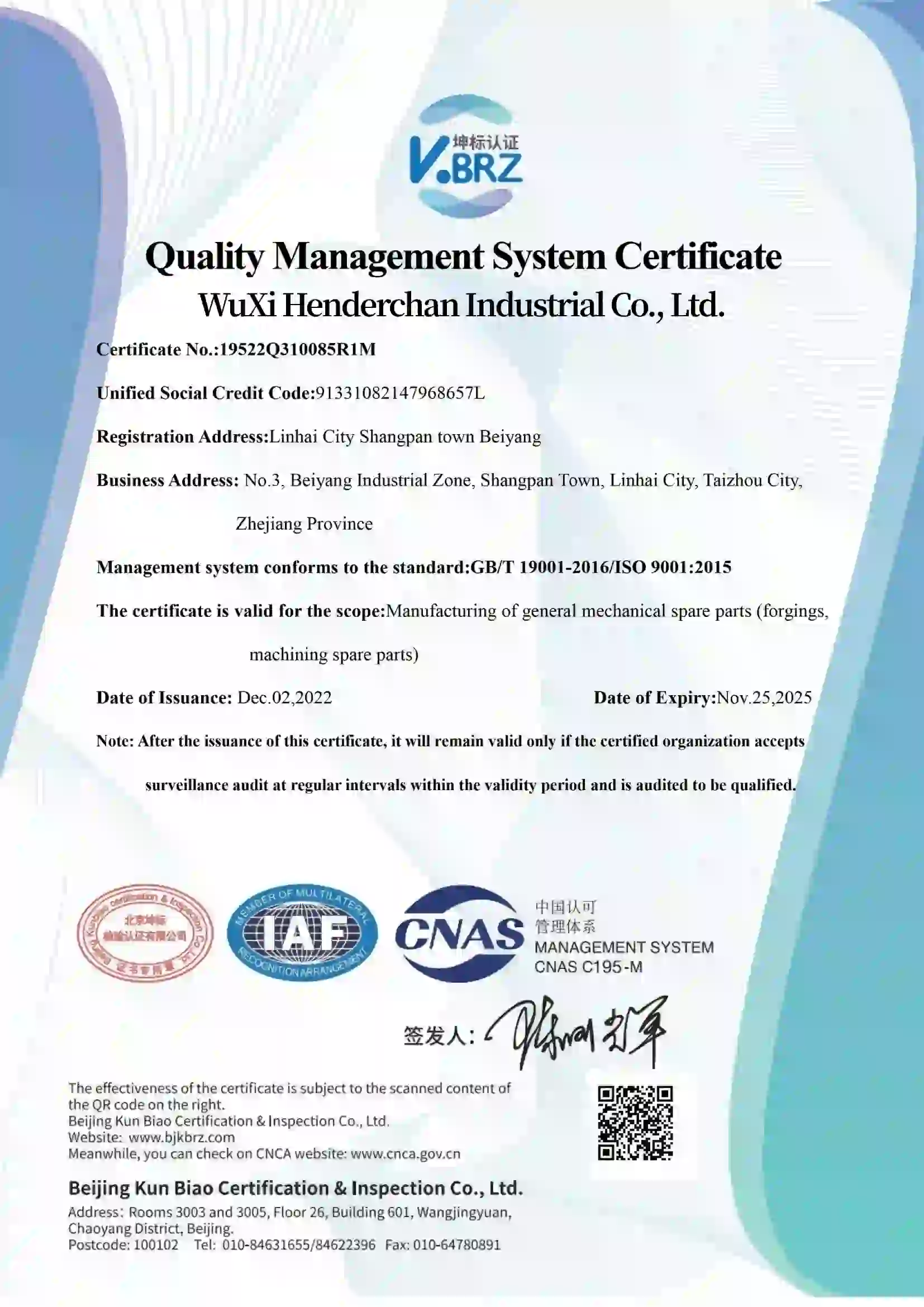

• ISO 9001 Certified

• Global Service

• One-Stop Solution

Our Casting Services

One-stop casting services from casting to final finishing, designed for high-demand applications

Investment Casting

Precision lost-wax casting for complex geometries with exceptional surface finish and dimensional accuracy.

- Complex internal geometries

- Tight tolerances ±0.05mm

- Superior surface finish Ra 1.6μm

- Near-net-shape manufacturing

Learn More

Heat Treatment

Advanced thermal processing to optimize mechanical properties and microstructure for superior performance.

- Solution annealing treatments

- Aging and precipitation hardening

- Stress relief annealing

Learn More

CNC Machining

Precision machining services for tight tolerances and superior surface finishing.

- 5-axis CNC machining center

- Tolerances to ±0.05mm

- Surface finishes to Ra 0.8μm

- Thread cutting and tapping

- In-process quality control

Learn More

Materials & Surface Finishes

Over 20+ metal materials are available in HDC to satisfy requirements in different applications

Superalloys

Nickel-Based Superalloys

Inconel 713C, Inconel 738LC, Mar-M 247, Hastelloy X

Cobalt-Based Superalloys

X-40, Mar-M 509

Iron-Nickel-Based Superalloys

A-286, Incoloy 901, Incoloy 800H

Surface Treatments

Pickling

Remove oxide scale, residual shell material, release agent, etc.

Sand Blasting

Remove surface impurities and improve surface roughness for coating

Bead Blasting

Improve surface stress and enhance stress corrosion resistance

Electroplating

Improve wear resistance and corrosion resistance

Need Custom Solutions?

With rich experience in the casting process, material configuration, composition analysis, physical property testing, heat treatment technology, etc., HDC provides you with the best solution

Industry We Serve

HDC superalloy casting serves industries worldwide, which mainly include the following industries

Aerospace

Turbine blades, compressor disks, combustion chambersEnergy

Gas turbine blades, heat exchangers, nuclear reactor componentsAutomotive

Turbocharger turbines, exhaust valves, turbocharger housingsIndustrial

Chemical reactor vessels, pump impellers, furnace partsMarine

Propeller shafts, marine turbine blades, exhaust systems

Quality Assurance & Certifications

Our commitment to excellence is backed by comprehensive quality management systems and international certifications. Every casting undergoes rigorous testing and inspection to ensure it meets the highest industry standards.

Testing Capabilities:

- Chemical composition analysis (RSA)

- Mechanical property testing (Hardness, Tensile)

- Dimensional inspection (CMM)

Why Choose HDC

Advanced Facilities

Advanced casting equipment ensure consistent quality and precision in every product.

Expert Team

15+ years of experience in superalloy casting with capabilities in metallurgical engineering

Global Certification

Process global certificates, including: ISO 9001:2015, ISO 14001:2015, IATF 16949, ISO 45001:2015

Custom Solutions

Tailored casting solutions designed to meet your specific requirements and application challenges.

R&D Support

In-house research and development capabilities for alloy optimization and process improvement.

Global Reach

Worldwide shipping and logistics support with established partnerships in major industrial markets.

How HDC Cast Superalloy

Learn about our comprehensive casting service workflow

Superalloy is hard to process by manufacturing methods like CNC machining, forging, and welding due to its superior mechanical properties.

The most commonly used method to process superalloy is investment casting. Its ability to cast complex internal cavities, thin-walled structures, curved surfaces, and nearly any shape of parts makes it preferred by industries that require high-temperature resistant components.

As a factory specializing in investment casting, we have over 15 years of experience and provide custom superalloy investment casting services tailored for your projects.

HDC has developed a detailed casting process and strictly implemented it to ensure the quality of superalloy castings, and the complete workflow is shown in the figure.

More About HDC

Discover HDC's advanced machinery and casting facility for precision superalloy castings

| Equipment | Specifications | Quantity |

| Wax Injection Machines | – | 5 |

| Vacuum Melting Furnaces | 50kg, 100kg capacity | 2 |

| Medium Frequency Induction Furnaces | 250kg (2 units), 100kg (1 unit) | 3 |

| Shell Baking Furnaces | – | 2 |

| Heat Treatment Furnaces | – | 2 |

| Shot Blasting Machines | – | 5 |

| Sand Blasting Machines | – | 2 |

| Spectrometer | SPECTRO Germany, 5th Gen. Direct-Reading | 1 |

| Tensile Testing Machine | – | 1 |

| Power Supply System | 630kVA Box-type Transformers | 2 |

What is Super Alloy

Superalloy, also known as “high-temperature alloy”, is a type of high performance metal material specially developed for applications under extremely high temperatures over 1000°C.

Key Properties of Superalloy

- Superior high-temperature strength

- Excellent creep resistance

- Excellent resistance to oxidation and corrosion

- Good fatigue resistance

Types of Super Alloy

Based on the main matrix elements, superalloys can be primarily divided into three categories:

- Nickel-based: The most widely used, offering the best overall high temperature performance.

- Cobalt-based: Superior resistance to thermal corrosion and thermal fatigue at higher temperatures, but also has higher density and cost.

- Iron-nickel-based: Relatively low cost, performance between nickel-based and heat-resistant stainless steels, use at lower temperatures or in environments that require less extreme.

In addition to the base elements, the key alloying elements of superalloy include chromium, aluminum, titanium and some elements with extremely high melting points, such as tungsten, molybdenum, rhenium, tantalum and niobium. By adjusting the content of various elements, the performance of superalloy can be precisely controlled to adapt to various application scenarios.

FAQ

We cast parts from 0.5 kg to 50 kg with tolerances as tight as ±0.1 mm. Complex geometries with thin walls (as thin as 0.5 mm) are achievable.

We use vacuum melting and advanced shell systems to minimize impurities. Each batch undergoes chemical analysis and mechanical testing per ASTM standards.

We accept common CAD file formats, including STEP, DWG. PDF drawings are also acceptable.

For prototypes, the lead time is typically around 4-6 weeks, and for production runs, typically 8-12 weeks.

Yes, we provide certificates per the customer's requirements.

We ship globally via DHL/FedEx (small parts) or air/ocean freight (large batches), with FOB or DDP incoterms options. Export documentation is provided.

Yes, we are responsible for defects caused by casting process and materials, and provide free remake service.

Request Free Quote

Related Resources

316 Stainless Steel: Composition,

316 stainless steel is austenitic type alloy which possesses good...

Die Casting Service

Custom Die Casting Service, Global Trusted OEM Factory One-stop die...

Steel Casting Service

One-Stop Steel Casting Products Solution Provider As an expert steel...

Aluminum Casting Service

Precision Custom Aluminum Casting Service Transform your designs into precision...