CNC Machining Titanium Materials

HDC for CNC Machining Titanium Materials

Titanium is a popular material nowadays, as its desirable strength-to-weight ratio, and high corrosion resistance, are widely used in medical, automotive, and aerospace industries.

Titanium Grade 1, Titanium Grade 2, and Titanium Grade 5 are the three common titanium materials we machine, we can machine custom titanium parts for your projects

Why Choose Us

High Accuracy

Equipped with an industry-leading 5 Axis machine and skilled technician team, we can meet your high precision requirements, not only in prototyping but also in production.

On-Time delivery

We make the delivery as promised schedule, we do as we said, we can the delivery for samples in 20 days and production in 30 days

Quality Assurance

We have an experienced quality control team to ensure all the measures within the tolerance As ISO9001 certificated manufacturer, we have a complete quality system from the material, machine, and surface treatment to packing.

Design Protected

We protect your designs, all your designs are not allowed to show to any third party, and will have a Non-disclosure Agreement with you

Available materials

Titanium Grade 1, is commercially pure metal, unalloyed, and widely used in lots of applications, due to its excellent corrosion resistance property, good machinability, and high weldability

Titanium Grade 2, similar to Titanium Grade 1, is unalloyed titanium, also equally corrosion resistant, but it is a bit stronger, and widely used in aerospace, marine, and medical industries.

Titanium grade 5 is the most widely used alloy titanium, with 800+ MPA yield strength, It is commonly suitable for many applications, such as aerospace it is harder than Titanium Grade 2

FAQ

Is Titanium hard to machine?

Titanium is one of the most difficult machinability materials, but due to its desirable properties, Titanium is commonly used in the medical and aerospace industries.

Is titanium easier to machine than steel?

As Titanium has high yield strength than steel, it is harder to machine than steel

Is Titanium harder to machine than stainless steel?

Titanium is harder to machine than stainless steel, as the yield strength of stainless steel 304 is around 170MPA, while it is 800 MPA for Titanium Grade5

Why does titanium have poor machinability?

Titanium is very strong, with excellent material properties

What are the grades of titanium?

Titanium has commercially pure grades and titanium alloy grades,

-Grade 1 to Grade 4 are commercially pure grades, see below the difference

–Grade 7, Grade 11, and Grade 12 are titanium alloy grades, but near commercially pure titanium.

–Titanium Grade 5, the most common use industrial Titanium, we also call Titanium 6Al-4V

Is Titanium Grade 2 or Grade 5 better?

Titanium Grade 2 is, unalloyed, All Titanium, Titanium Grade 5 is alloy Titanium,

Titanium grade5 is stronger than grade 2, it depends on your requirements to choose which one.

CNC Machining Titanium Materials FAQS

CNC machining titanium materials is a manufacturing process that’s farfetched, especially for some suppliers. But we here at HDC Manufacturing are more than happy to help you with all the CNC titanium parts and components you need!

Before we get to that, though, our team prepared this guide to help and guide you from A to Z when it comes to CNC machining titanium materials!

Can You Cut Titanium on a CNC Machine?

Figure 1 –PVD-coated titanium part

Yes, thanks to titanium’s desirable properties, titanium will not give you any type of headache when it comes to machining – not to mention CNC machining, in itself, too. Just like stainless steel, titanium can easily be welded and machined in an inert standard atmosphere.

In addition to this flexibility, titanium can also be bent and bowed multiple times in necessary conditions. So, to help you out with this further, do you know what specific CNC machines are used in processing or machining titanium?

What Material is Used to Machine Titanium?

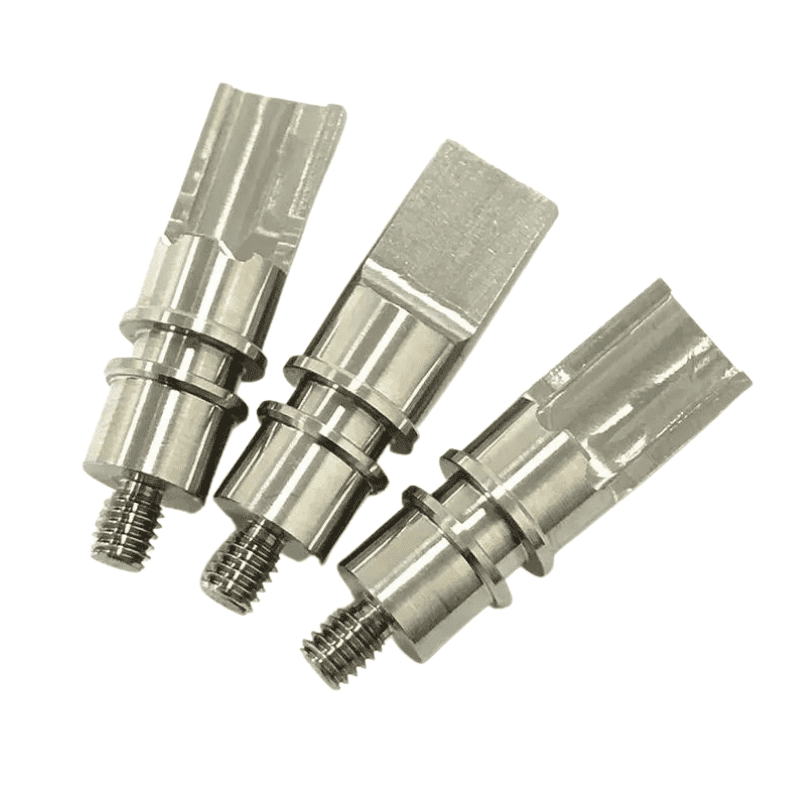

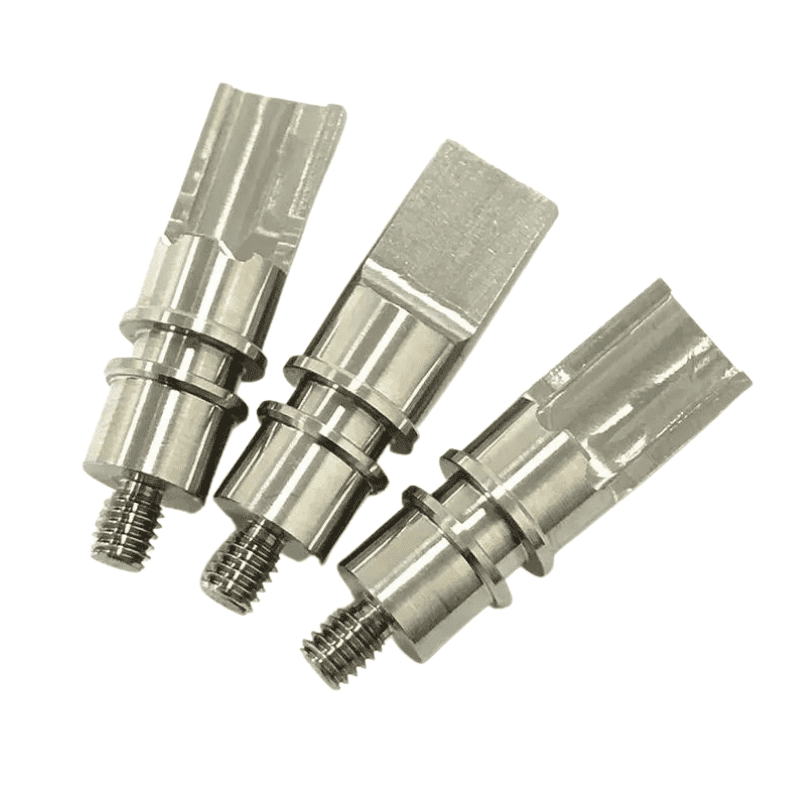

Figure 2 – A titanium part or component cut by carbide

There is a wide array of materials used for the purpose of cutting, slicing, processing, and machining titanium. However, the most trusted material for machining titanium is none other than carbide.

Being one of the hardest and yet ductile materials in the market, carbide will never fail you when you are looking to machine titanium.

Besides the fact that it has a wide temperature range, it also boasts of a high thermal conductivity, high elasticity modulus, and it would not break down even if subdued to pressure and force – that is tolerable, of course.

Carbide is labelled only as the best in machining titanium. However, apart from carbide, you’ll also be able to find other materials such as ceramics, cast alloys, and even high-speed steel.

NOTE: Some manufacturers also use laser cutting, waterjet cutting, and even plasma cutting machines in slicing and machining titanium!

What Titanium Parts and Components Can You CNC Machine?

Figure 3 – Titanium-built turbine blades

There are a lot of titanium parts and components you can find that are actually made via CNC machines. And although the majority of these products would have the subtlest and slightest of differences, you will notice their indifferences especially when it comes to the measurements and overall precision and accuracy of the parts and components.

To name some of the few most common parts and components CNC machines have made in history, here they are:

- Turbine Blades and Engines

- Engine Parts and Components

- Medical Screws and Latches

- Dental and Medical Implants

- Discs and Shafts

- And Many More!

What Grade of Titanium is the Easiest to Machine?

According to expert structural engineers and professional manufacturers, the best and most convenient titanium grade to manufacture is Pure Titanium. The reason for this is because of three (3) major factors:

- They have extremely high flexibility

- The heat conductivity of titanium is low

- Most titanium alloys have high hardness levels

- They are ultimately lightweight, making it easy to machine

Although pure titanium alloys are what many experts consider the easiest and most convenient to machine, we here at HDC Manufacturing choose Titanium Grade 5 for most parts and components that require it.

Besides the fact that it has a relatively low thermal conductivity, it’s also not going to mess and tamper with the overall condition of it because the temperature will be maintained even while it’s being processed or machined.

CNC Machining Titanium vs. Stainless Steel

Figure 4 – CNC machined titanium (left); CNC machined stainless steel (right)

Usability-wise, titanium and stainless steel are two (2) very different materials. They’re set on the same foot, and it’s something that needs to be identified by manufacturers as it is an important ingredient in making sure that the parts and components are highly accurate.

We want to make your lives easier, and for that, we’re presenting a table that you can look back to in case you want to check the better material for the current project you are on.

Titanium | Stainless Steel | |

Composition | Nitrogen, Oxygen, Carbon, Iron, Nickel, and Hydrogen | Almost the same composition, but they have about 11% more Chromium (also has molybdenum, selenium, nickel, sulphur, etc.) |

Corrosion Resistance | More corrosion resistant than stainless steel | Corrosion resistant but will come at a time where it can be corroded |

Thermal Conductivity | Conductivity runs from 118 BTU-in/hr-ft²-°F | Conductivity runs from 69.4 to 238 BTU-in/hr-ft²-°F |

Electrical Conductivity | Poor electrical conductivity | Poor electrical conductivity, but about 0.4% better than titanium |

Melting Point | Titanium has a melting point of 3000 to 3040 °F | Stainless Steel has a melting point of 2250 to 2790°F |

Hardness | Fairly hard in the Brinell scale | Fairly hard in the Brinell scale |

So, in case you have questions and doubts between using stainless steel and titanium in terms of machining, here are the differences they have! Now, you don’t have to guess what’s better for the current project that you are working on!

Where Can You Get High-Quality CNC Machining Titanium Materials?

If you are looking for high-quality CNC machining titanium parts and components, you can never go wrong in choosing us here at HDC Manufacturing. We are experts and professionals in the processing and machining of various categories of titanium, including Titanium Grades 1, 2, and even 5!

You can bank and count on us here at HDC Manufacturing if you are looking for CNC machining titanium materials for automotive, medical, aerospace and aeronautical, and even manufacturing industries!

We have exceptional skill and experience when it comes to producing premium quality CNC machining titanium materials such as jet engine parts, ship components, rocket engine cases, airframe components, chemical parts and components, medical and medicinal parts, and many more!

What Other Services Can HDC Manufacturing Help You With?

Apart from CNC machining titanium materials, we here at HDC Manufacturing are also trustworthy when it comes to laser cutting services, aluminum forging, sheet metal fabrication service, CNC rapid prototyping, and many more!

Contact us and we’ll be more than happy to help you by sending a free estimate of what you’re planning to order!

[toc]